Preparation method and application of Gr/BPA-Si nano hybrid material and fireproof coating

A technology of nano-hybrid materials and fire-resistant coatings, applied in fire-resistant coatings, epoxy resin coatings, coatings, etc., can solve the problems of low carbon layer strength, uneven foaming, poor oxidation resistance, etc., and achieve high carbon layer strength. , The effect of improving the strength of the carbon layer and the strong oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

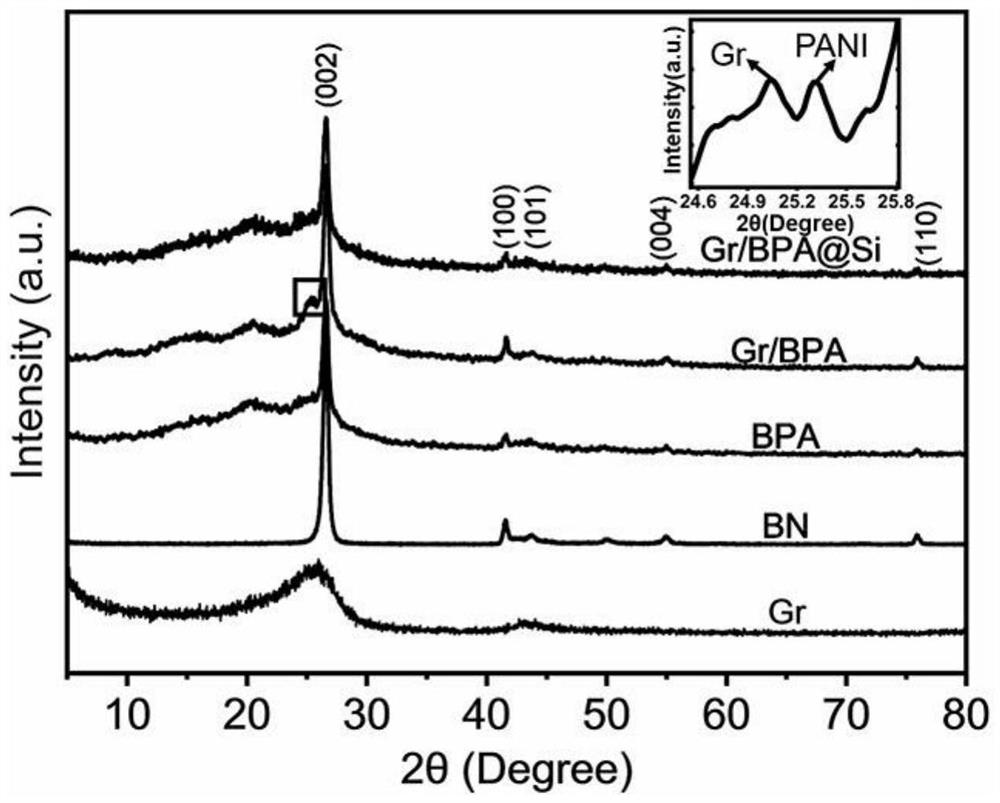

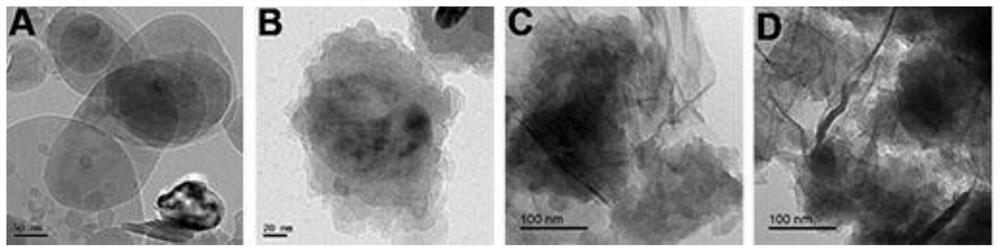

[0055] A preparation method of a Gr / BPA@Si nano-hybrid material, comprising: S1. dispersing BPA in anhydrous ethanol to obtain a first dispersion; S2. dispersing Gr in the first dispersion to obtain a second dispersion liquid; S3. Under stirring, drop the ethanol solution of oligomeric silsesquioxane into the second dispersion liquid at 75 °C, react for 45 h, and obtain Gr / BPA@Si nano-hybrid material after treatment; BPA and low The mass ratio of polysilsesquioxane was 1:0.4.

[0056] The preparation method of BPA includes: T1. mixing hexagonal boron nitride, aniline monomer and water to obtain a suspension; T2. adding dropwise an aqueous hydrochloric acid solution of ammonium persulfate to the suspension (the concentration of HCl in the aqueous hydrochloric acid solution is 0.05mol / L), and BPA was obtained after 6 hours of reaction at 0 °C; the mass ratio of aniline monomer and ammonium persulfate was 1:2.5; the mass ratio of BPA and hexagonal boron nitride was 1:0.05.

[00...

Embodiment 2

[0059] A preparation method of a Gr / BPA@Si nano-hybrid material, comprising: S1. dispersing BPA in anhydrous ethanol to obtain a first dispersion; S2. dispersing Gr in the first dispersion to obtain a second dispersion liquid; S3. Under stirring, drop the ethanol solution of oligomeric silsesquioxane into the second dispersion liquid at 85 °C, react for 55 h, and obtain Gr / BPA@Si nanohybrid material after treatment; BPA and low The mass ratio of polysilsesquioxane was 1:0.5.

[0060] The preparation method of BPA includes: T1. mixing hexagonal boron nitride, aniline monomer and water to obtain a suspension; T2. adding dropwise an aqueous hydrochloric acid solution of ammonium persulfate to the suspension (the concentration of HCl in the aqueous hydrochloric acid solution is 0.05mol / L), BPA was obtained after 6h reaction at 5°C; the mass ratio of aniline monomer and ammonium persulfate was 1:3.5; the mass ratio of BPA and hexagonal boron nitride was 1:0.15.

[0061] The prepar...

Embodiment 3

[0063] A preparation method of a Gr / BPA@Si nano-hybrid material, comprising: S1. dispersing BPA in anhydrous ethanol to obtain a first dispersion; S2. dispersing Gr in the first dispersion to obtain a second dispersion liquid; S3. Under stirring, drop the ethanol solution of oligomeric silsesquioxane into the second dispersion liquid at 80 °C, react for 48 h, and obtain Gr / BPA@Si nano-hybrid material after treatment; BPA and low The mass ratio of polysilsesquioxane was 1:0.45.

[0064] The preparation method of BPA includes: T1. mixing hexagonal boron nitride, aniline monomer and water to obtain a suspension; T2. adding dropwise an aqueous hydrochloric acid solution of ammonium persulfate to the suspension (the concentration of HCl in the aqueous hydrochloric acid solution is 0.05mol / L), and BPA was obtained after 8 hours of reaction at 3 °C; the mass ratio of aniline monomer and ammonium persulfate was 1:3; the mass ratio of BPA and hexagonal boron nitride was 1:0.1.

[0065...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com