Heavy oil hydrogenation reaction system and heavy oil hydrogenation method

A heavy oil hydrogenation and reaction system technology, applied in the field of heavy oil hydrogenation, can solve the problems of high energy consumption and investment, complex process flow, etc., and achieve the effects of high material viscosity, improved reaction rate, and wide applicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

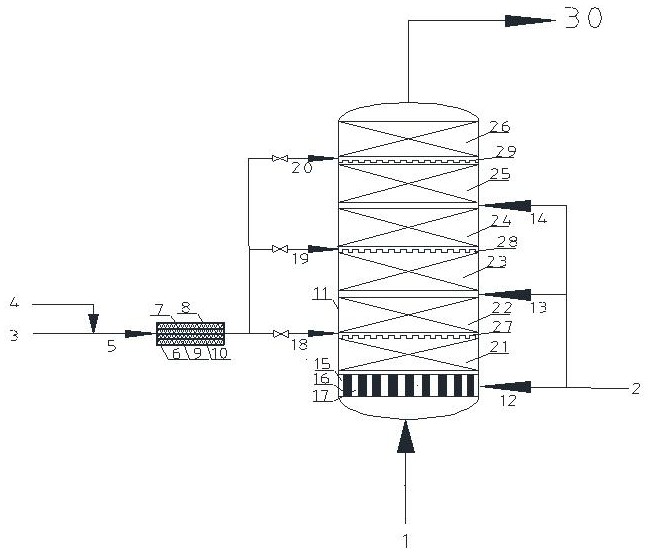

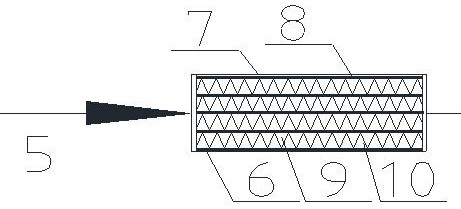

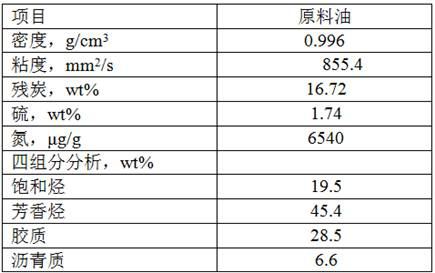

[0046] Using the heavy oil hydrogenation reaction system and heavy oil hydrogenation method described in the present invention, firstly, the heavy oil raw material and hydrogen II are respectively introduced into the bottom and side of the heavy oil hydrogenation reactor, the hydrogen II enters the shell space of the feed mixer, and the heavy oil The raw material enters the membrane dispersion tube bundle of the feed mixer, and the hydrogen II permeates and diffuses into the membrane dispersion tube bundle from the shell space under the pressure difference, mixes with the heavy oil in the tube bundle to form a homogeneous phase, and then enters the first catalyst bed layer to generate gasification. hydrogen reaction. The heavy oil hydrogenation reactor is divided into 2 beds. From bottom to top, the first bed is filled with hydrogenation protection agent (70v%) and hydrodemetallization agent (30v%) in sequence, and the second bed is filled with Hydrodesulfurization agent (60v%...

Embodiment 2

[0051] Using the heavy oil hydrogenation reaction system and heavy oil hydrogenation method described in the present invention, firstly, the heavy oil raw material and hydrogen II are respectively introduced into the bottom and side of the heavy oil hydrogenation reactor, the hydrogen II enters the shell space of the feed mixer, and the heavy oil The raw material enters the membrane dispersion tube bundle of the feed mixer, and the hydrogen II permeates and diffuses into the membrane dispersion tube bundle from the shell space under the pressure difference, mixes with the heavy oil in the tube bundle to form a homogeneous phase, and then enters the first catalyst bed layer to generate gasification. hydrogen reaction. The heavy oil hydrogenation reactor is divided into 3 beds. From bottom to top, the first catalyst bed is filled with hydrogenation protection agent, and the second catalyst bed is filled with hydrodemetallization agent (60v%) and hydrodesulfurization agent (40v%)...

Embodiment 3

[0056] Using the heavy oil hydrogenation reaction system and heavy oil hydrogenation method described in the present invention, firstly, the heavy oil raw material and hydrogen II are respectively introduced into the bottom and side of the heavy oil hydrogenation reactor, the hydrogen II enters the shell space of the feed mixer, and the heavy oil The raw material enters the membrane dispersion tube bundle of the feed mixer, and the hydrogen II permeates and diffuses into the membrane dispersion tube bundle from the shell space under the pressure difference, mixes with the heavy oil in the tube bundle to form a homogeneous phase, and then enters the first catalyst bed layer to generate gasification. hydrogen reaction. The heavy oil hydrogenation reactor is divided into 4 beds. From bottom to top, the first bed is filled with hydrogenation protection agent, the second bed is filled with hydrodemetallization agent, and the third bed is filled with hydrodesulfurization agent. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com