Three-function heterostructure catalyst as well as preparation method and application thereof

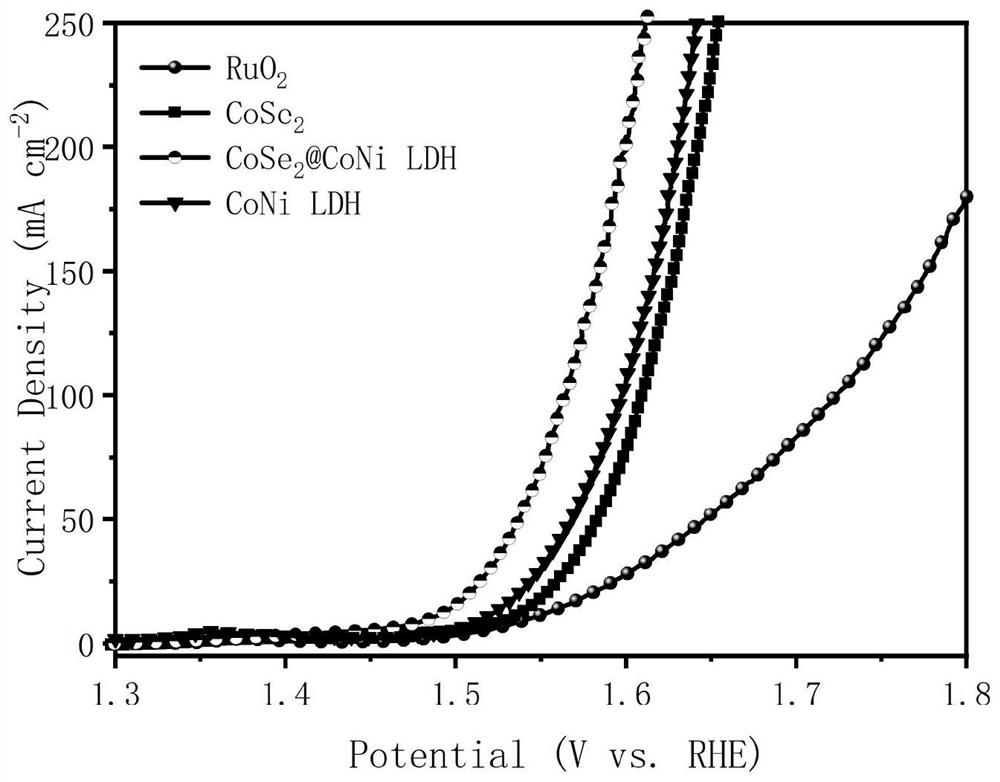

A heterogeneous structure, three-function technology, applied in the direction of structural parts, electrolytic components, electrolytic process, etc., can solve the problems that restrict the large-scale commercial development of electrolyzed water and metal-air batteries, and achieve good catalytic activity, stability, and multi-activity The effect of site and structure stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

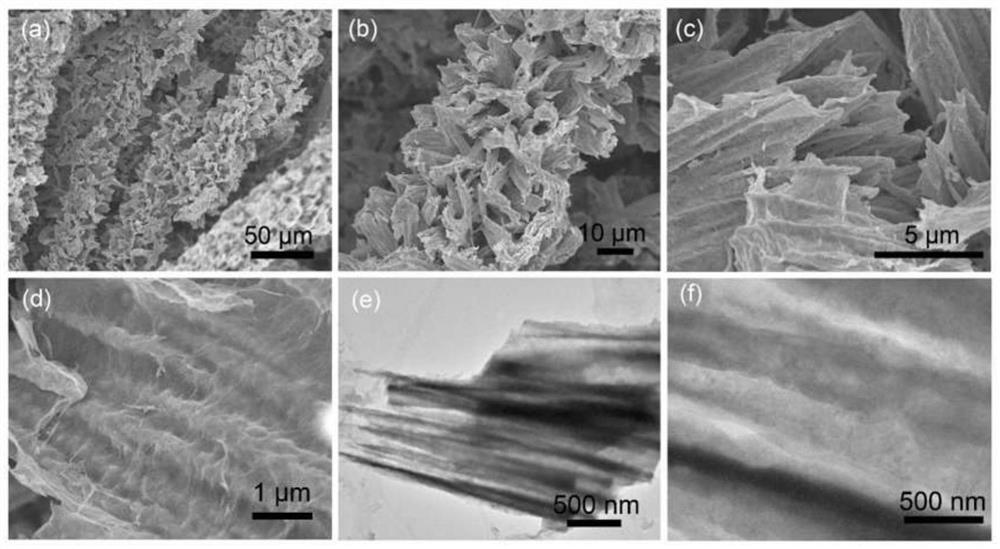

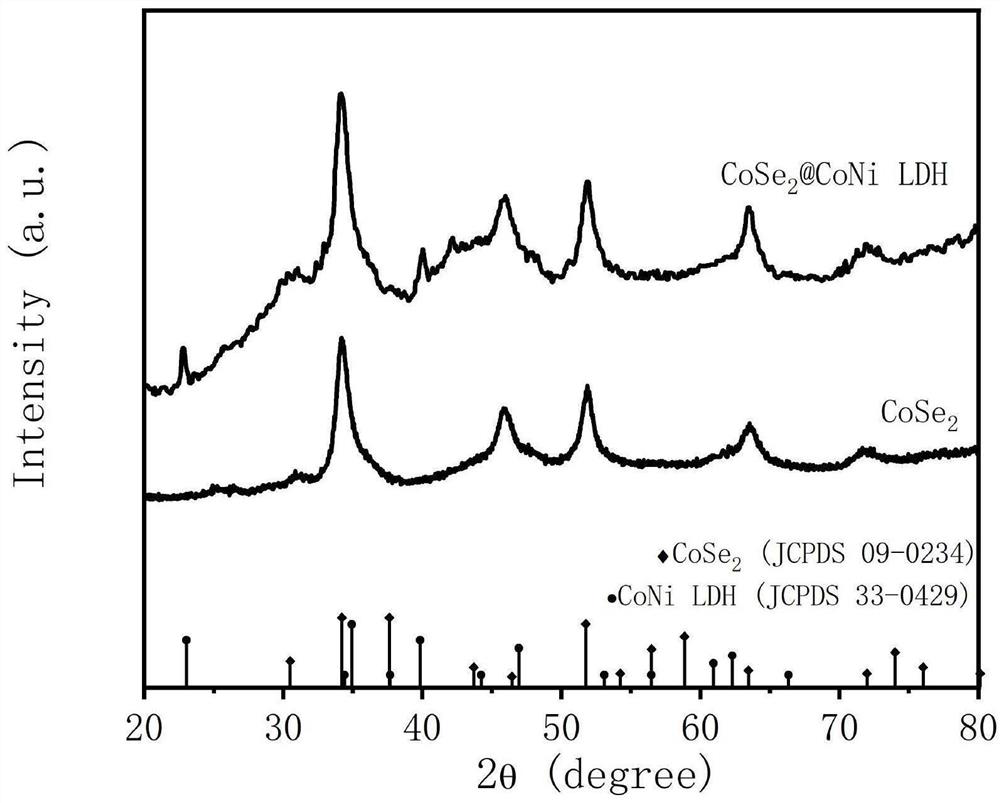

[0039] The present embodiment for a flexible zinc-air battery with a three-functional heterostructure catalyst comprises a carbon cloth and a composite layer disposed on the surface of the carbon cloth, the composite layer comprises CoSe 2 Nanotubes, CoSe 2 The nanotubes are coated with CoNi LDH material.

[0040] The preparation method of the present embodiment for a flexible zinc-air battery with a three-functional heterostructure catalyst comprises the following steps:

[0041] 1) Carbon cloth pretreatment

[0042] Cut the carbon cloth into 1.0cm*2.5cm, sonicate in 1mol / L aqueous hydrochloric acid solution, deionized water and ethanol in turn, and then dry in a vacuum drying box at 60 °C;

[0043] 2) Generation of nanowire precursors

[0044]1.0 g of cobalt chloride hexahydrate, 0.3 g of urea and 0.3 g of ammonium fluoride were added to 30 mL of deionized water, well stirred to dissolve, and then transferred to a 50 mL reactor; then added two pieces of carbon cloth treated in ...

Embodiment 2

[0050] The present embodiment for a flexible zinc-air battery with a three-functional heterostructure catalyst comprises a carbon cloth and a composite layer disposed on the surface of the carbon cloth, the composite layer comprises CoSe 2 Nanotubes, CoSe 2 The nanotubes are coated with FeNi LDH material.

[0051] The preparation method of the present embodiment for a flexible zinc-air battery with a three-functional heterostructure catalyst comprises the following steps:

[0052] 1) Carbon cloth pretreatment

[0053]Cut the carbon cloth into 1.0cm*2.5cm, sonicate in 1mol / L aqueous hydrochloric acid solution, deionized water and ethanol in turn, and then dry in a vacuum drying box at 60 °C;

[0054] 2) Generation of nanowire precursors

[0055] 1.0 g of cobalt chloride hexahydrate, 0.3 g of urea and 0.3 g of ammonium fluoride were added to 30 mL of deionized water, well stirred to dissolve, and then transferred to a 50 mL reactor; then added two pieces of carbon cloth treated in ...

Embodiment 3

[0061] The present embodiment for a flexible zinc-air battery with a three-functional heterostructure catalyst comprises a carbon cloth and a composite layer disposed on the surface of the carbon cloth, the composite layer comprises CoSe 2 Nanotubes, CoSe 2 The nanotubes are coated with MnNi LDH material.

[0062]The preparation method of the present embodiment for a flexible zinc-air battery with a three-functional heterostructure catalyst comprises the following steps:

[0063] 1) Carbon cloth pretreatment

[0064] Cut the carbon cloth into 1.0cm*2.5cm, sonicate in 1mol / L aqueous hydrochloric acid solution, deionized water and ethanol in turn, and then dry in a vacuum drying box at 60 °C;

[0065] 2) Generation of nanowire precursors

[0066] 1.0 g of cobalt chloride hexahydrate, 0.3 g of urea and 0.3 g of ammonium fluoride were added to 30 mL of deionized water, well stirred to dissolve, and then transferred to a 50 mL reactor; then added two pieces of carbon cloth treated in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com