MEMS resonant pressure sensor with on-chip in-situ temperature measurement compensation function

A pressure sensor and resonant technology, which is applied in the field of MEMS resonant pressure sensors, can solve the problems of large temperature hysteresis error of the sensor, difficulty in ensuring comprehensive accuracy, and long time to stabilize when power is turned on, so as to improve comprehensive accuracy, simple circuit, The effect of shortening the settling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

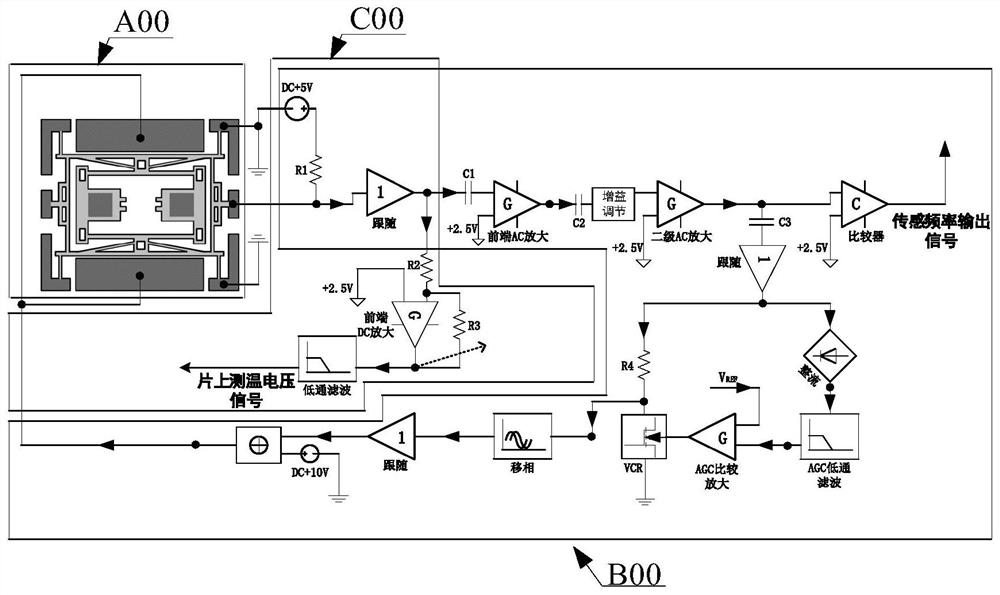

[0060] Such as figure 1 As shown, a MEMS resonant pressure sensor with an on-chip in-situ temperature measurement and compensation function includes a sensitive chip A00, a closed-loop resonant detection circuit B00 electrically connected to the sensitive chip A00, and a temperature detection circuit C00;

[0061] The sensitive chip A00 is used for resonant sensing pressure and in-situ temperature sensing, the closed-loop resonance detection circuit B00 is used for closed-loop detection of the frequency sensed by the sensitive chip A00 to reflect the pressure sensed by the sensitive chip A00, and the temperature detection circuit C00 is used for The voltage sensed by the sensitive chip A00 is detected to reflect the temperature sensed by the sensitive chip A00 in situ.

Embodiment 2

[0063] Such as figure 1 As shown, a MEMS resonant pressure sensor with an on-chip in-situ temperature measurement and compensation function includes a sensitive chip A00, a closed-loop resonant detection circuit B00 electrically connected to the sensitive chip A00, and a temperature detection circuit C00;

[0064] The sensitive chip A00 is used for resonant sensing pressure and in-situ temperature sensing, the closed-loop resonance detection circuit B00 is used for closed-loop detection of the frequency sensed by the sensitive chip A00 to reflect the pressure sensed by the sensitive chip A00, and the temperature detection circuit C00 is used for Detecting the voltage sensed by the sensitive chip A00 to reflect the temperature sensed by the sensitive chip A00 in situ;

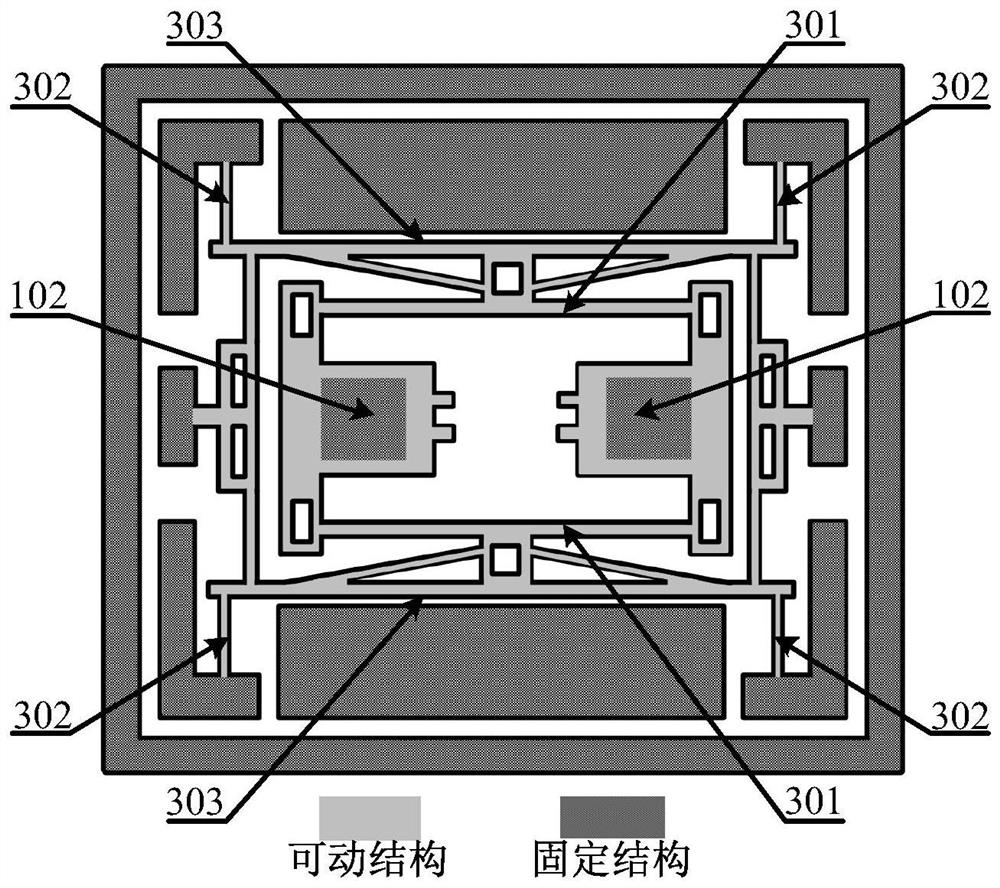

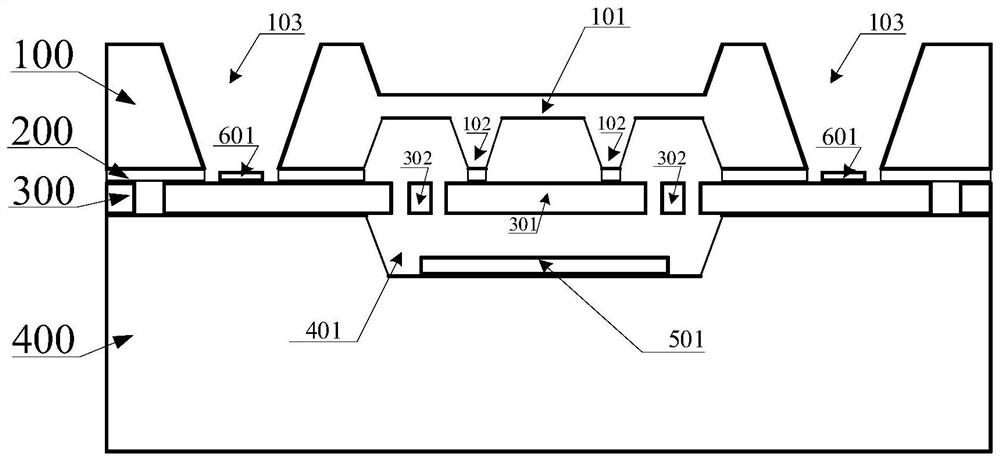

[0065] Such as Figure 2-3 As shown, the sensitive chip A00 includes Si pressure sensitive layer 100, SiO 2 Electrical isolation layer 200, Si resonator layer 300 and glass pit substrate layer 400;

[0066] T...

Embodiment 3

[0082] Such as figure 1 As shown, a MEMS resonant pressure sensor with on-chip in-situ temperature measurement and compensation function consists of three parts: a sensitive chip A00, a closed-loop resonant detection circuit B00, and a temperature detection circuit C00. The sensitive chip A00 is used for resonant sensing of pressure. The micro-nano structure and the micro-nano structure of resistance sensing temperature, the closed-loop resonant detection circuit B00 and the temperature detection circuit C00 are shared by the front-end resistor divider and voltage follower module circuit.

[0083] Such as figure 2 Shown is the top view of the sensitive chip of the sensor of the present invention, as image 3 Shown is the sectional view of the sensitive chip of the sensor of the present invention. It can be seen from the figure that the sensitive chip is composed of 4 layers, and the pressure sensitive layer 100 is SiO from top to bottom. 2 Electrical isolation layer 200, Si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com