Single-fiber vortex optical tweezers and manufacturing method and modulation method thereof

A production method and vortex light technology, applied in the field of optical tweezers, can solve the problems of inability to achieve four-dimensional over-control, and the inability of fiber optical tweezers to fully meet new requirements, and achieve the effects of simple and easy operation, cost, and strong focusing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

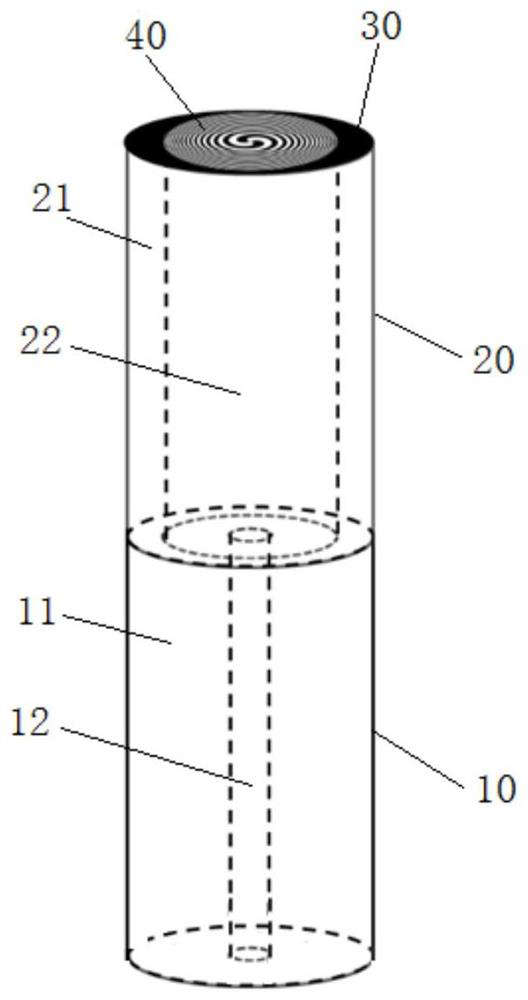

[0057] A specific embodiment of the present application provides a single-fiber vortex optical tweezers for etching a helical zone plate 40 on an optical fiber end face.

[0058] Such as figure 1 As shown, the single-fiber vortex optical tweezers include a single-mode fiber 10 and a graded-index multimode fiber 20 . Single-mode fiber, English name Single Mode Fiber, referred to as SMF. Graded Index Fiber, English name Graded IndexFiber, referred to as GIF. Wherein, one end of the single-mode optical fiber 10 is directly fused with the graded-index multimode optical fiber 20 to form a combined single-fiber vortex optical tweezers. There is a light-shielding film layer 30 on the fiber end face of the graded-index multimode fiber 20 ; the helical zone plate 40 is formed on the light-shielding film layer 30 . The spiral zone plate 40 forms a light-transmitting bright zone and an opaque dark zone on the light-shielding film layer 30 .

[0059] In this application, the single-mo...

Embodiment 2

[0092] A specific embodiment of the present application provides a method for manufacturing a single-fiber vortex optical tweezers for etching a spiral zone plate 40 on the end face of an optical fiber described in Embodiment 1, including the following steps:

[0093] S1, splicing a section of graded-index multimode optical fiber 20 at the end of the single-mode optical fiber 10;

[0094] S2, prepare a spiral zone plate formed by a light-shielding film layer on the fiber end face of the graded-index multimode optical fiber 20, and the spiral zone plate 40 forms a light-transmitting bright wave zone and an opaque wave zone on the light-shielding film layer 30 dark band.

[0095] In step S1, the single-mode fiber 10 and the graded-index multimode fiber 20 can be spliced by a fiber fusion splicer first, and then the graded-index multimode fiber 20 is cut to a corresponding required length by a fiber precision cutter. The precision cutting system consists of an optical fiber cu...

Embodiment 3

[0123] A specific embodiment of the present application provides a single-fiber vortex optical tweezers modulation technology, and the single-fiber vortex optical tweezers are as described above. Light with different wavelengths is input at the end of the single-mode optical fiber 10, and the axial capture of particles is controlled by controlling the wavelength of the incident light, so that the position of the focused light field can be adjusted in the axial direction.

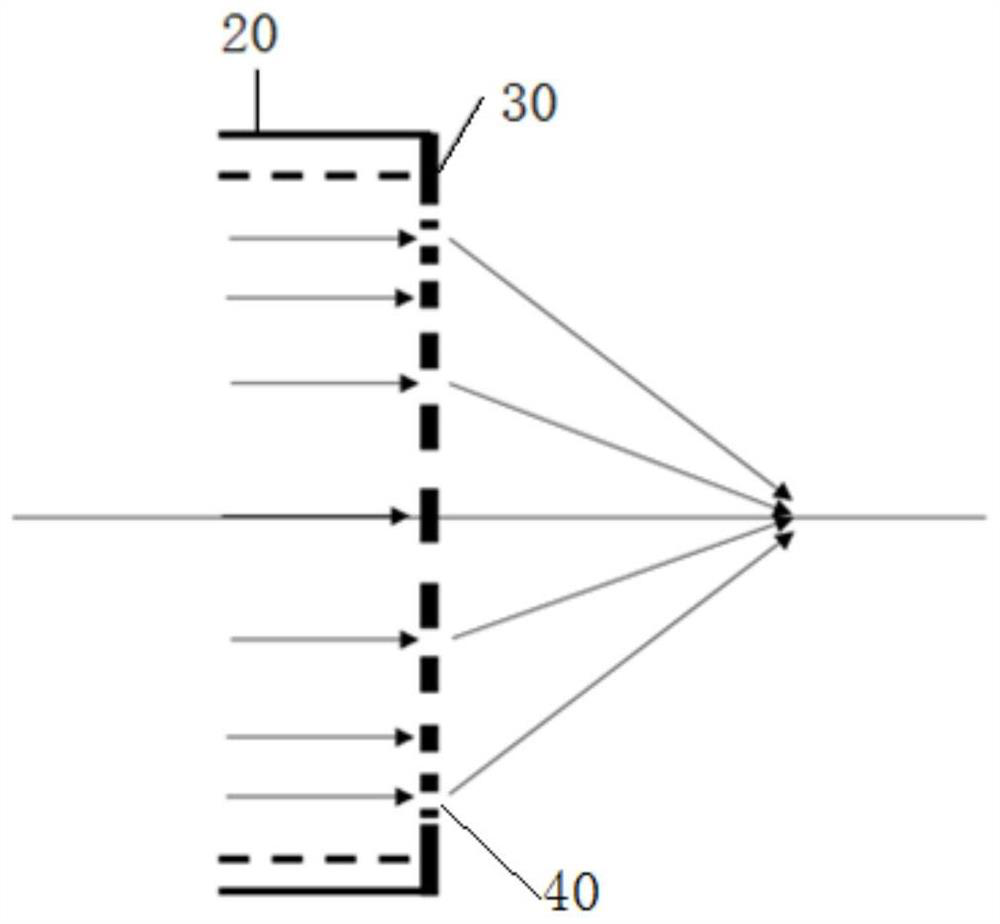

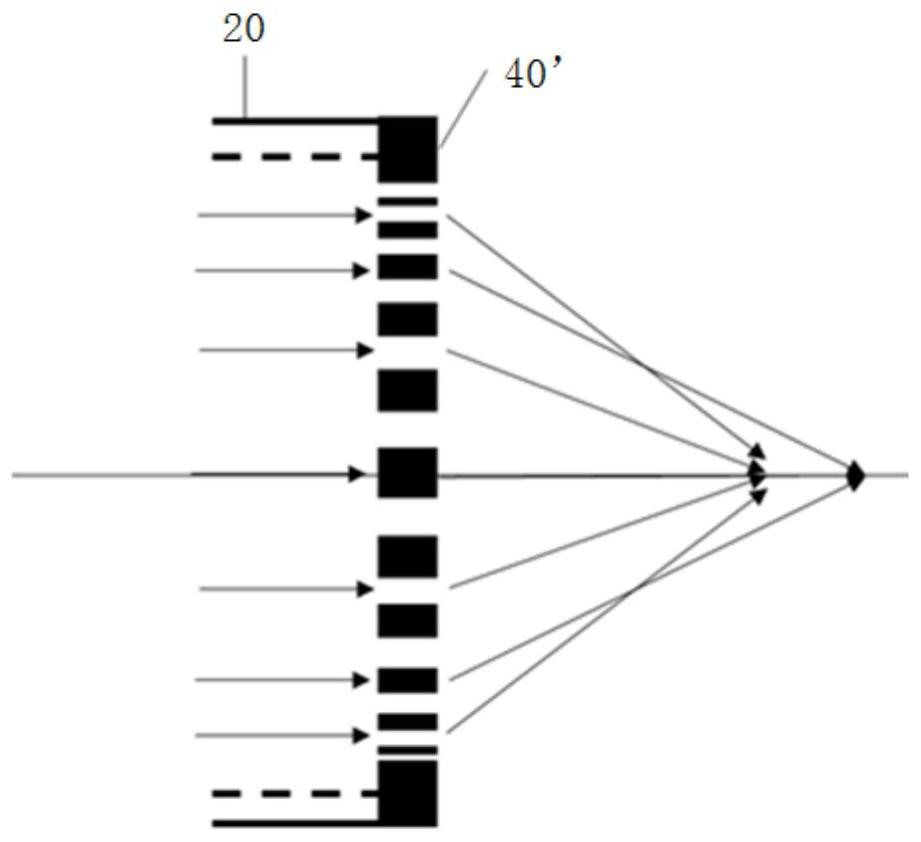

[0124] Since the primary diffraction point is uniquely determined, according to the design principle of the helical zone plate 40, when the size of the helical zone plate 40 is fixed, the focal length of the focused light field obtained will change when the optical fiber inputs different wavelengths, and the wavelength The longer the focal length is, the shorter the focal length is, and the focus of the beam is closer to the end face of the fiber; on the contrary, when the wavelength of the incident light dec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com