Composite electrolyte film, preparation method thereof and application of composite electrolyte film in solid-state lithium battery

A technology of composite electrolyte and gel electrolyte, which is applied in the field of composite electrolyte film and its preparation, can solve the problems of poor chemical properties and mechanical properties, and achieve the effects of ensuring uniform dispersion, increasing interface contact area, and improving structural uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1: The preparation method of the composite electrolyte film of the present embodiment is carried out according to the following steps:

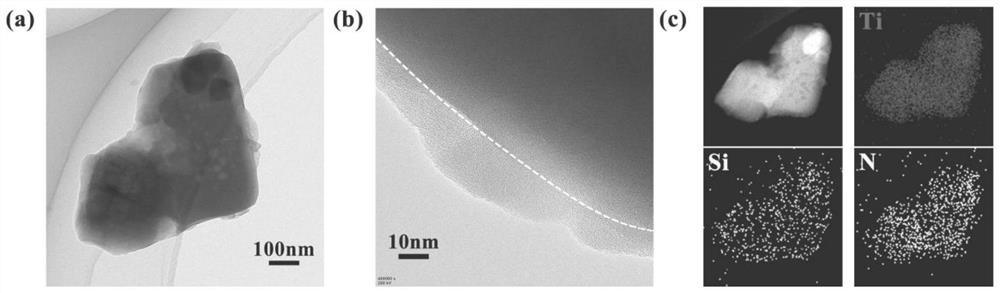

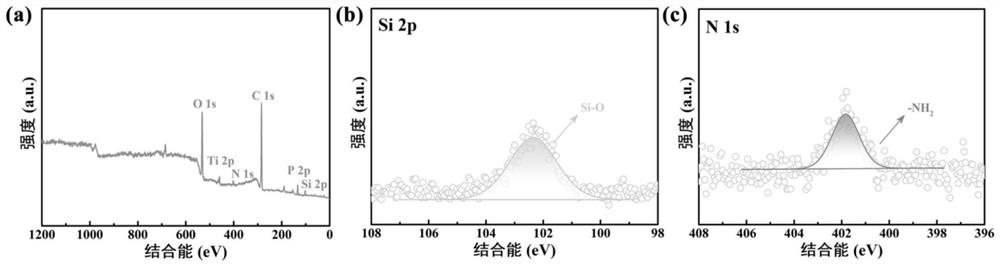

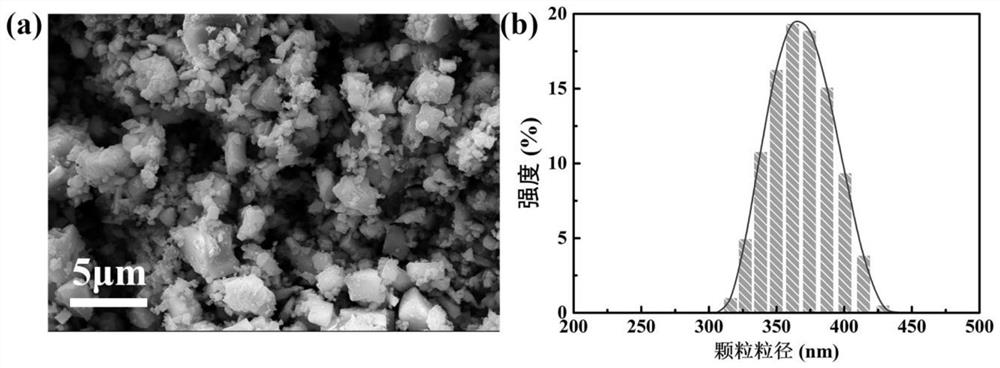

[0058] 1. Preparation of surface treatment agent-coated lithium ion conductor filler: Mix 45mL of absolute ethanol, 2.5mL of deionized water and 1.25mL of glacial acetic acid evenly, stir for 3 hours to stabilize the pH value, and then add 5mL of surface treatment agent 3-aminopropyl base triethoxysilane, continue to stir for 5h to obtain a mixed solution; 1g of lithium ion conductor type filler aluminum doped titanium lithium phosphate (Li 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 , LATP) were dispersed in the mixed solution, and stirred at a temperature of 60°C for 10 hours to obtain a dispersion; the dispersion was centrifuged and washed in turn, and repeated three times; Vacuum drying at ℃ for 12 hours to obtain polysiloxane-coated aluminum-doped lithium titanium phosphate particles;

[0059] 2. Preparation of electrospinning sol...

Embodiment 2

[0102] Embodiment 2: The preparation method of the composite electrolyte film of the present embodiment is carried out according to the following steps:

[0103] 1. Preparation of surface treatment agent-coated lithium ion conductor filler: Mix 45mL of absolute ethanol, 2.5mL of deionized water and 1.25mL of glacial acetic acid evenly, stir for 3 hours to stabilize the pH value; add 5mL of surface treatment agent 3-aminopropyl Triethoxysilane, continue to stir for 5h; 1g of lithium ion conductor type filler aluminum doped titanium lithium phosphate (Li 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 , LATP) dispersed in the above solution, heated and stirred at 60°C for 10h to form a dispersion; centrifuged and washed the obtained dispersion in turn, and repeated three times; sucked out the upper solvent after the third centrifugation, and took out the remaining solid phase at the bottom , after vacuum drying at 60°C for 12 hours, polysiloxane-coated aluminum-doped lithium titanium phosphate ...

Embodiment 3

[0110] Embodiment 3: The preparation method of the composite electrolyte film of the present embodiment is carried out according to the following steps:

[0111] 1. Preparation of surface treatment agent-coated lithium ion conductor filler: Mix 45mL of absolute ethanol, 2.5mL of deionized water and 1.25mL of glacial acetic acid evenly, stir for 3 hours to stabilize the pH value; then add 5mL of surface treatment agent 3-aminopropyl base triethoxysilane, continue to stir for 5h; 1g of lithium ion conductor type filler aluminum doped lithium titanium phosphate (Li 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 , LATP) dispersed in the above solution, heated and stirred at 60°C for 10 hours to form a dispersion; centrifuged and washed the obtained dispersion in turn, and repeated three times; sucked out the upper solvent after the third centrifugation, and took out the remaining solid phase at the bottom After vacuum drying at 60°C for 12 hours, polysiloxane-coated aluminum-doped lithium titani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com