Porous battery diaphragm material and manufacturing method and application of porous battery diaphragm material

A technology of battery diaphragm and font, which is applied in the field of porous battery diaphragm material preparation, can solve the problems of inability to meet the requirements of high-rate alkaline batteries, equipment investment, high comprehensive production cost, poor electrolyte permeability, etc., and achieve excellent chemical stability The effect of ensuring high temperature safety performance, improving safety and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) The "rice" type PP / PE bicomponent composite fiber with a fiber diameter of 11 μm was cut into short fibers with a length of 5 mm by a disc fiber cutter.

[0027] (2) The short fiber prepared in the step (1) is subjected to a high-speed rotary cutting beating treatment to prepare a fiber slurry with a concentration of 5%, using water as a dispersion medium, and sodium dodecylsulfonate as a dispersant.

[0028] (3) The fiber slurry prepared in step (2) is subjected to isobaric sizing by a central sizing device, and then passed through a hydraulic inclined-net headbox to form a single-network and double-layer inclined-network.

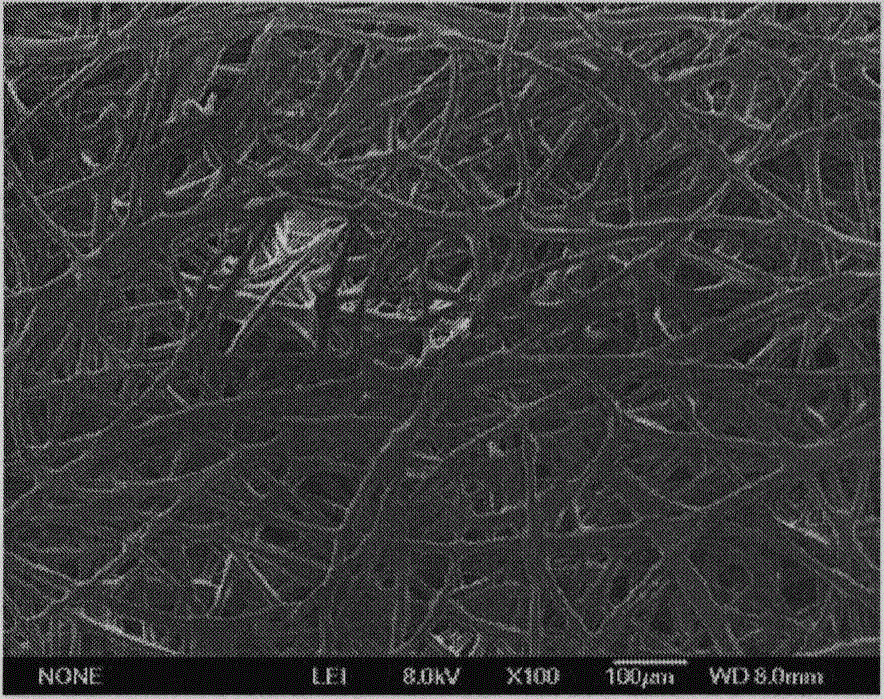

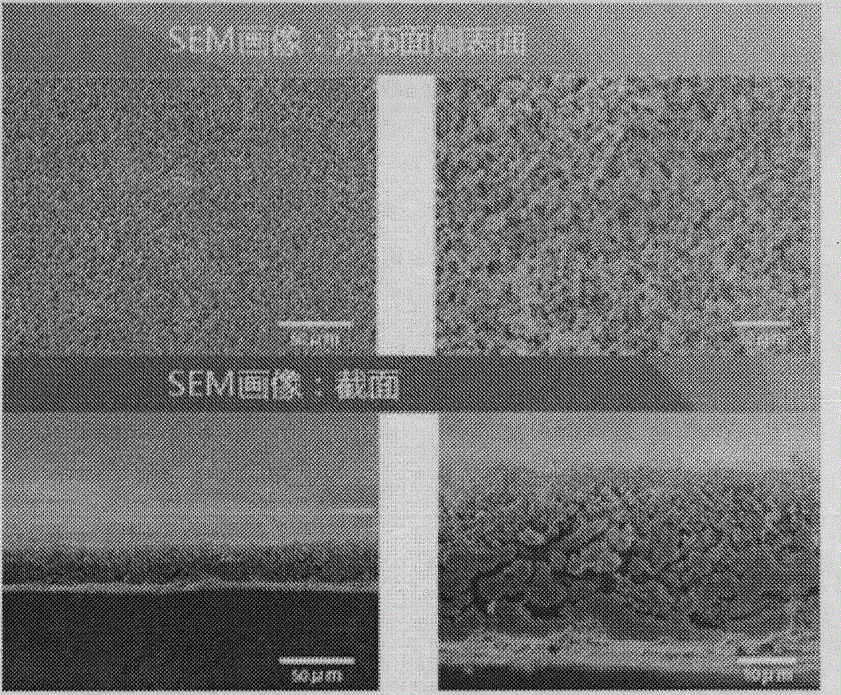

[0029] (4) After dehydration and pressing, dry in a drying tunnel with hot air at 135°C, and prepare a surface density of 60g / m 2 The porous battery separator material, its structure see figure 1 .

[0030] (5) The prepared porous battery diaphragm material is subjected to sulfur trioxide gas-phase sulfonation treatment to obtain an alkaline ...

Embodiment 2

[0034] (1) The "ten" type PET / PP bicomponent composite fiber and single component polyester fiber with a fiber diameter of 3 μm were cut into short fibers with a length of 5 mm by a disc fiber cutter.

[0035] (2) The short fiber PET / PP composite fiber, polyester fiber and nanocellulose fiber, aluminum oxide fiber prepared by step (1) are uniformly prepared in a mass fraction of 40:35:10:5 with the absolute dry mass of the fiber Mixing, high-speed rotary cutting, beating, and dissolving treatment, to prepare fiber slurry with a concentration of 2%, using water as the dispersion medium, and sodium dodecylbenzenesulfonate as the dispersant.

[0036] (3) The fiber slurry prepared in step (2) is subjected to isobaric sizing by a central sizing device, and then passed through a hydraulic inclined-net headbox to form a single-network and double-layer inclined-network.

[0037] (4) After dehydration and pressing, dry in a drying tunnel with hot air at 170°C, and prepare a surface den...

Embodiment 3

[0042] The specific implementation steps are as follows:

[0043] (1) The "rice" type PET / PP bicomponent composite fiber and single component polyester fiber with a fiber diameter of 3 μm were cut into short fibers with a length of 5 mm by a disc fiber cutter.

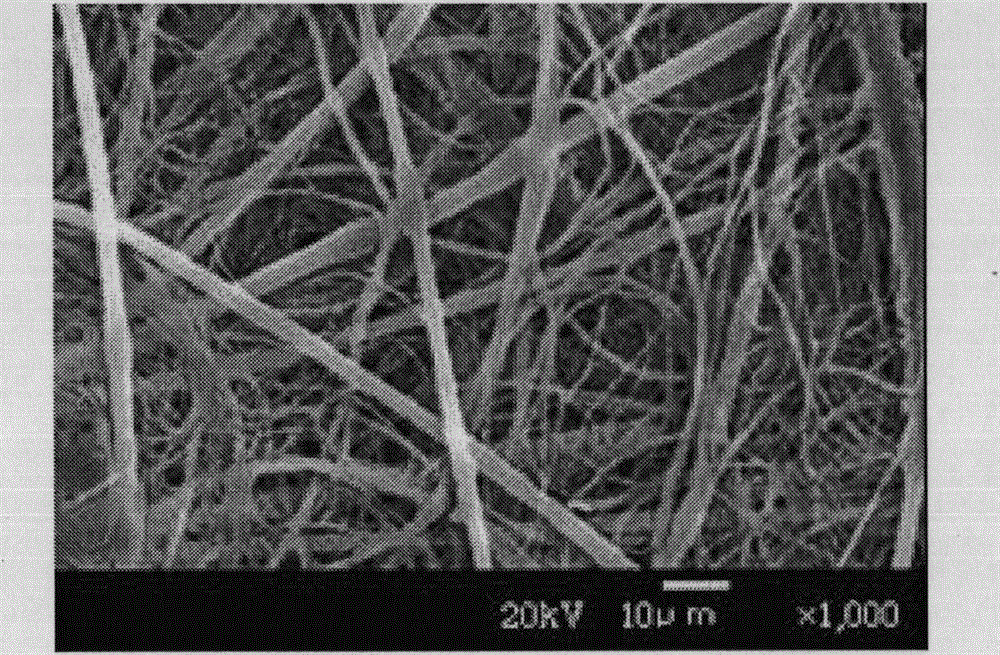

[0044] (2) The cut PET / PP composite staple fibers, polyester staple fibers and nanocellulose fibers are uniformly mixed with the absolute dry weight of the fibers at a mass fraction of 10:10:80, and are treated by high-speed rotary cutting beating and dissolving, A fiber slurry with a concentration of 1% is prepared, water is used as a dispersion medium, and sodium dodecylbenzenesulfonate is used as a dispersant.

[0045](3) The fiber slurry prepared in step (2) is subjected to isobaric sizing by a central sizing device, and then passed through a hydraulic inclined-net headbox to form a single-network and double-layer inclined-network.

[0046] (4) After dehydration and pressing, dry in a drying tunnel with hot air at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com