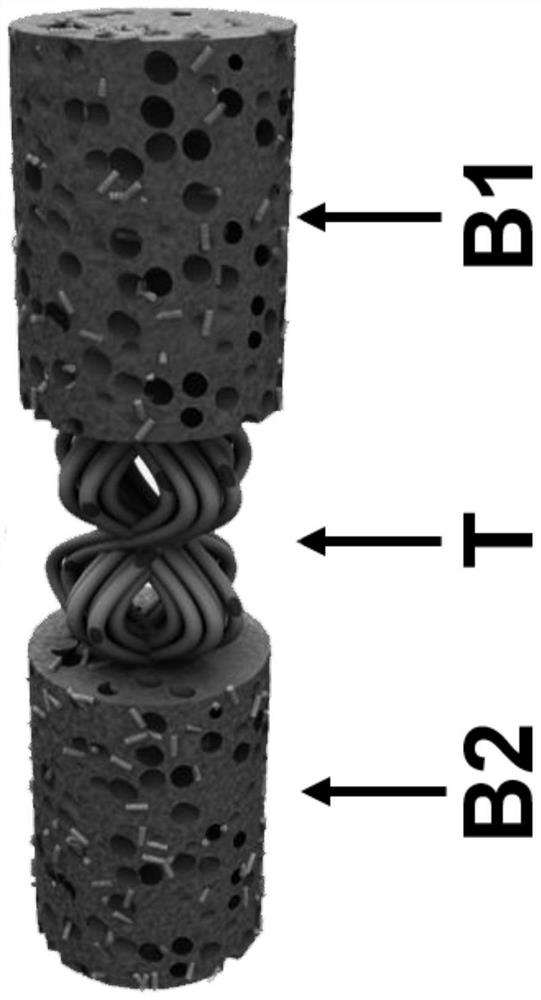

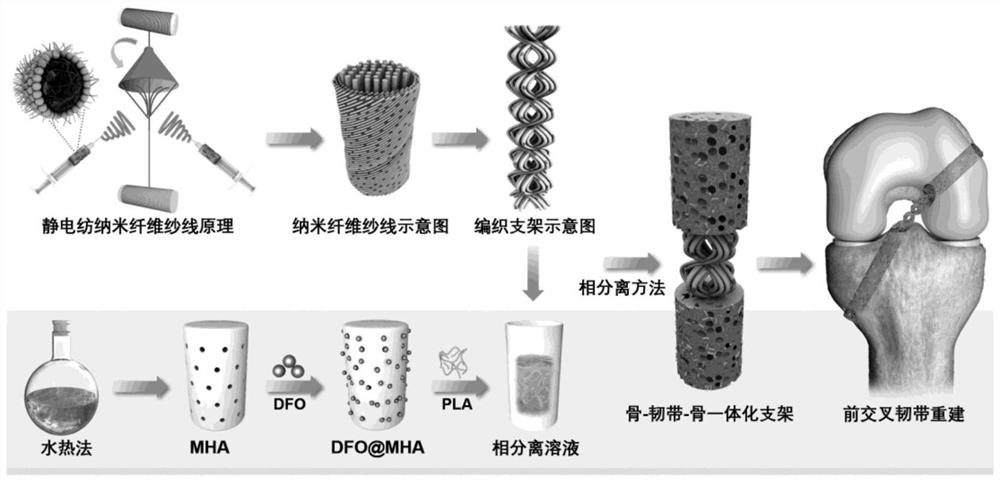

Bone-ligament-bone integrated stent and preparation method thereof

A technology of bone scaffold and ligament, which is applied in the field of bone-ligament-bone integrated scaffold and its preparation, can solve the problems of simultaneous repair of ligament and bone in the joint cavity, and achieve the advantages of cell ingrowth, strong mechanical properties, The effect of promoting bone healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

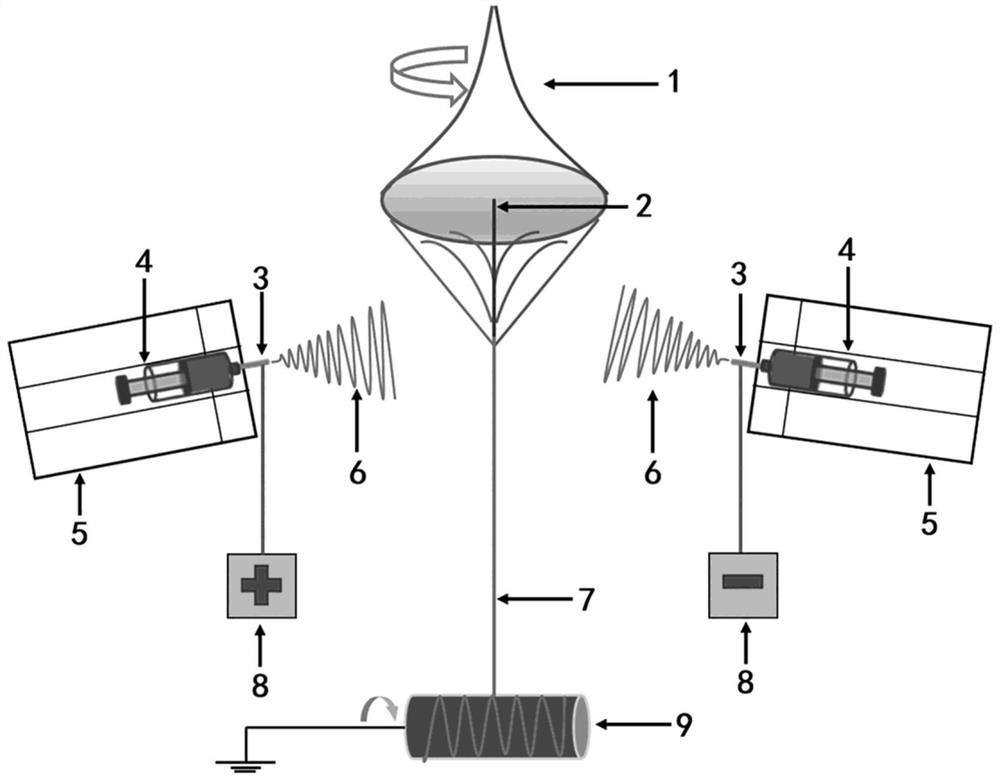

[0060] In this example, the silk fibroin thread (100-200 μm in diameter; Shanghai Tongjieliang Biomaterials Co., Ltd.) is used as the core layer of the nanofiber yarn, and the spinning solution is prepared by blending the polymer PLCL and the connective tissue growth factor CTGF , using mesoporous hydroxyapatite (MHA) to support deferoxamine (DFO) and polymer PLA to form a phase separation solution. Concrete preparation process is as follows:

[0061] S1: Preparation of spinning solution: prepare CTGF (PeproTech, USA) solution with a concentration of 2 μg / mL in phosphate buffer, accurately measure 10 mL of dichloromethane (purchased from Sinopharm Chemical Reagent Co., Ltd.) in a glass bottle, At the same time, 0.1 mL of Span 80 (purchased from Aladdin Biochemical Technology Co., Ltd.) and 0.5 mL of CTGF solution were added dropwise to the dichloromethane solution, then stirred at high speed for 12 h, and finally 1.0 g of PLCL (M w =80000, Jinan Daigang Biotechnology Co., Ltd...

Embodiment 2

[0082] In this example, PLA wires are used as the core layer of nanofiber yarns, the high molecular polymer PCL is used to prepare the spinning solution, and silicon dioxide and poly(lactic-co-glycolic acid) (PLGA) are used to form a phase-separated solution. Concrete preparation process is as follows:

[0083] S1: Preparation of spinning solution: accurately weigh 1.0g PCL (M w =100000, Shenzhen Guanghua Weiye Co., Ltd.) was dissolved in 10mL hexafluoroisopropanol (purchased in Shanghai Darui Fine Chemicals Co., Ltd.), stirred overnight, and was made into a PCL spinning solution with a mass volume concentration of 0.1g / mL .

[0084] S2: Preparation of nanofiber yarn: as figure 1 As shown, the PLA thread 2 (50-100 μm in diameter; Shanghai Tongjieliang Biomaterials Co., Ltd.) was passed through the middle rotating funnel 1 of the multifunctional electrospinning machine as the core layer, and 10 mL of the spinning solution in S1 was transferred to Among the two counter-jet i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com