Photo-thermal interface evaporator and preparation method and application thereof

An evaporator and interface technology, applied in the field of photothermal interface evaporator and its preparation, can solve the problems of heat dissipation and inability to be effectively utilized by interface evaporation, so as to reduce heat dissipation, increase evaporation rate and energy efficiency, and improve The effect of heat buildup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

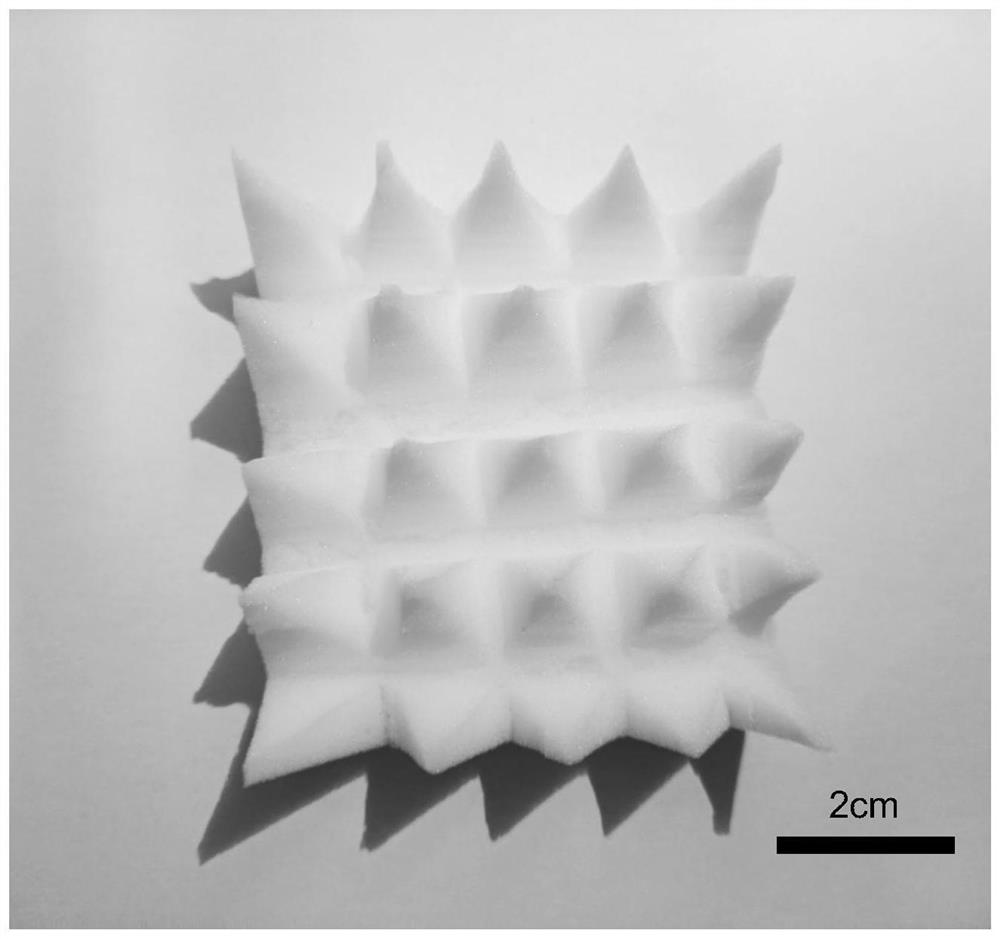

[0047] Cut the upper surface of a rectangular parallelepiped melamine foam (5cm × 5cm × 3cm) into an array of pyramidal protrusions, and the number of pyramidal protrusions is 5 × 5 ( figure 1 ), the height of the pyramid is about 1.5cm. figure 1 It is a digital photo of the melamine foam base with pyramidal protrusion array prepared in Example 1 of the present invention.

[0048] Mix 50g of graphene oxide aqueous dispersion with a concentration of 1wt%, 2.5g of carbon fiber, and 32.5g of deionized water evenly, mix at high speed for 10min, spread it on the PET base film and dry it to prepare a photothermal film. Fig. 2 is a digital photo of the dried photothermal film prepared in Example 1 of the present invention.

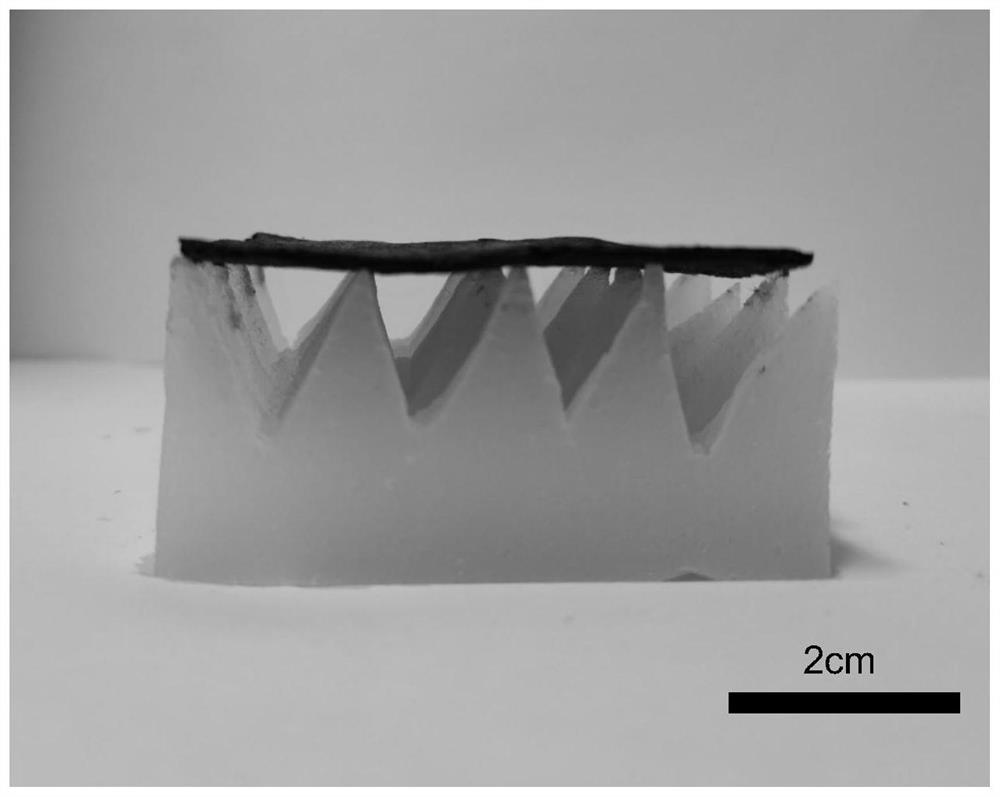

[0049] Fill the array of melamine foam pyramidal protrusions with water, cut the photothermal film to a suitable size, wet the surface with water, then place the photothermal film on the array, press lightly to make the two fit tightly, and form a photothermal i...

Embodiment 2

[0054] Cut the upper surface of a piece of cuboid polyvinyl alcohol foam into a triangular bar convex array, the size of the foam is 5cm×4cm×2cm, and the height of the protrusion is about 1cm. Figure 6 It is a digital photo of the polyvinyl alcohol foam triangular bar protrusion array prepared in Example 2 of the present invention.

[0055] 30g of copper nanowire aqueous dispersion with a concentration of 2wt% and 10g of polyaniline aqueous dispersion with a concentration of 2% were uniformly mixed by high-speed shearing, and then spread on a PTFE film to dry to prepare a photothermal film.

[0056] Absorb the protruding array of polyvinyl alcohol foam triangular strips with water, cut the photothermal film into a suitable size, wet the surface with water, then place the photothermal film on the array, press lightly to make the two fit tightly, and form a photothermal interface evaporator. With pure water as the evaporation object, at 1kw / m 2 The evaporation performance of ...

Embodiment 3

[0058] Cut the upper surface of a rectangular parallelepiped polyurethane sponge into an array of irregular protrusions, the size of the foam is 6cm×5cm×3cm, and the height of the protrusions is about 1.5cm. Figure 7 It is a digital photo of the polyurethane sponge special-shaped protrusion array prepared in Example 3 of the present invention.

[0059] 5 g of carbon black and 20 g of polypyrrole dispersion with a concentration of 1% were uniformly mixed by high-speed shearing, and then spread on a polypropylene film to dry to prepare a photothermal film.

[0060] Absorb the polyurethane sponge special-shaped convex array with water, cut the photothermal film into a suitable size, wet the surface with water, then place the photothermal film on the array, press lightly to make the two fit tightly, and form a photothermal interface evaporator . Taking seawater as evaporation object, at 1kw / m 2 The evaporation performance of the photothermal interface was tested under the simul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com