Spray dry granular glaze for ceramic tile surface decoration and preparation method of spray dry granular glaze

A surface decoration, dry-grain glaze technology, applied in the field of ceramics, can solve the problems of low strength of ordinary spray dry-grain glaze particles, unfavorable transportation and water dissolution, no plasticity, and high production cost, and achieves good fluidity, good plasticity, and use. Safe and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

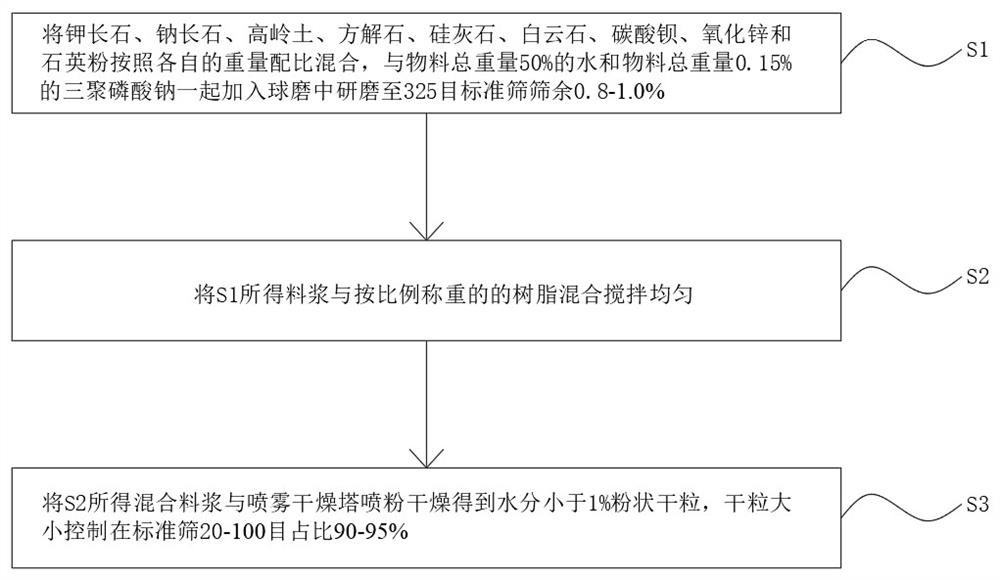

[0019] Such as figure 1 As shown, the present invention provides technical scheme, a kind of spray dry granular glaze that is used for ceramic tile surface decoration, comprises following raw material: potassium feldspar, albite, kaolin, calcite, wollastonite, Baiyunshan, barium carbonate, oxide Zinc, quartz powder, aluminum oxide, and resins to strengthen the pellets.

[0020] According to the above technical scheme, the raw materials are 25 parts of potassium feldspar, 30 parts of albite, 8 parts of kaolin, 5 parts of calcite, 8 parts of wollastonite, 6 parts of Baiyun Mountain, 5 parts of barium carbonate, and 6 parts of zinc oxide. 4 parts, 4 parts of quartz powder and one or several resin mixtures used to strengthen the strength of the particles, the total is 8 parts.

[0021] According to the above technical solution, the resin includes water-based fluorocarbon resin, water-based polyurethane resin, water-based acrylic resin, and water-based epoxy resin.

[0022] Accor...

Embodiment 2

[0027] Such as figure 1 As shown, the present invention provides technical scheme, a kind of spray dry granular glaze that is used for ceramic tile surface decoration, comprises following raw material: potassium feldspar, albite, kaolin, calcite, wollastonite, Baiyunshan, barium carbonate, oxide Zinc, quartz powder, aluminum oxide, and resins to strengthen the pellets.

[0028] According to the above technical scheme, the raw materials are 25 parts of potassium feldspar, 25 parts of albite, 10 parts of kaolin, 8 parts of calcite, 5 parts of wollastonite, 6 parts of Baiyun Mountain, 3 parts of barium carbonate, and 8 parts of zinc oxide. Parts, 2 parts of quartz powder and one or several resin mixtures for strengthening the strength of the particles, the total is 6 parts.

[0029] According to the above technical solution, the resin includes water-based fluorocarbon resin, water-based polyurethane resin, water-based acrylic resin, and water-based epoxy resin.

[0030] Accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com