Complete gradient alloy quantum dot and preparation method thereof

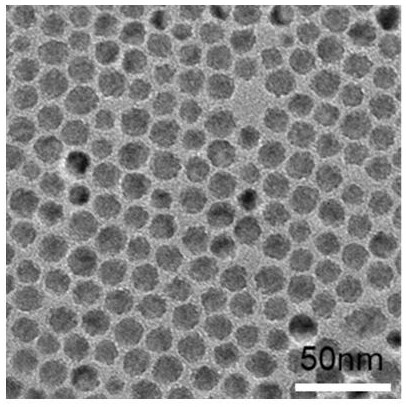

A gradient alloy and quantum dot technology, which is applied in chemical instruments and methods, nanotechnology for materials and surface science, luminescent materials, etc., can solve the problem of many defects at the interface, and achieve the reduction of lattice defects and stability Good, uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

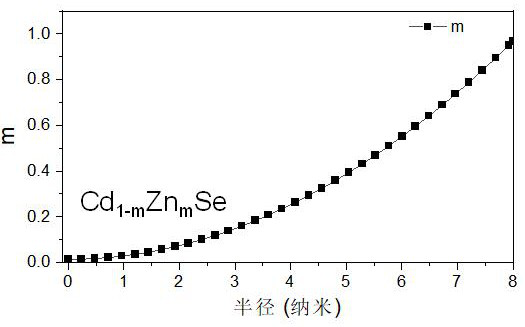

[0085] Preparation of Cd 1-m Zn m Se (0

[0086] Mix 1.2mmol zinc oleate, 1.6mmol cadmium oleate and 18mL octadecene to obtain a zinc source-cadmium source mixture; mix 10mmol selenium powder, 10mL trioctylphosphine and 10mL octadecene to obtain a selenium source material liquid;

[0087] The zinc source-cadmium source mixed material solution was heated up at a rate of 10°C / min from room temperature (25°C) to 310°C, then the selenium source material solution was added, and the reaction was carried out at 310°C for 60 minutes; after the reaction was completed, the obtained material was Naturally cool down to room temperature to obtain the cooled material, mix the cooled material with chloroform and ethyl acetate for sedimentation, and then centrifuge to obtain a solid phase of Cd 1-m Zn m Se (0<m<1) quantum dots; when the material is mixed with chloroform and ethyl acetate after cooling, the volume ratio of the material, chl...

Embodiment 2

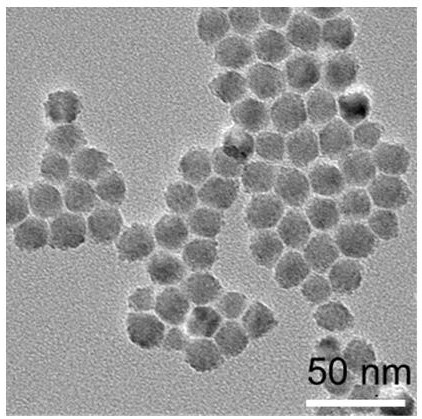

[0092] Preparation of Cd 1-m Zn m Se@8ZnSe y S 1-y (0

[0093] Mix 1.2mmol zinc oleate, 1.6mmol cadmium oleate and 18mL octadecene to obtain a zinc source-cadmium source mixture; mix 10mmol selenium powder, 10mL trioctylphosphine and 10mL octadecene to obtain a selenium source material 10mmol of sulfur powder, 10mL of trioctylphosphine and 10mL of octadecene were mixed to obtain a sulfur source mixture; 2mmol of zinc oleate and 5ml of octadecene were mixed to obtain a zinc source of liquid.

[0094] Get different volumes of selenium source material liquid and sulfur source material liquid and mix to obtain selenium source-sulfur source mixed material liquid; 2. Correspondingly recorded as selenium source-sulfur source mixed liquid Ⅰ, Ⅱ, Ⅲ, Ⅳ respectively.

[0095] The zinc source-cadmium source mixed material solution was heated at a rate of 10°C / min from room temperature (25°C) to 310°C, then the selenium source mat...

Embodiment 3

[0101] Preparation of Cd 1-m Zn m Se@10ZnSe y S 1-y (0

[0102] Preparation of Cd 1-m Zn m Se@10ZnSe y S 1-y (0

[0103] Mix 1.2mmol zinc oleate, 1.6mmol cadmium oleate and 18mL octadecene to obtain a zinc source-cadmium source mixture; mix 10mmol selenium powder, 10mL trioctylphosphine and 10mL octadecene to obtain a selenium source material 10mmol of sulfur powder, 10mL of trioctylphosphine and 10mL of octadecene were mixed to obtain a sulfur source mixture; 2mmol of zinc oleate and 5ml of octadecene were mixed to obtain a zinc source of liquid.

[0104] Raise the temperature of the zinc source-cadmium source mixed liquid at a rate of 10°C / min from room temperature (25°C) to 310°C, then add the selenium source liquid, and react at 310°C for 60 minutes; obtain Cd 1-m Zn m Se quantum dot solution.

[0105] Get different volumes of selenium source material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com