Lithium ion battery positive pole material, preparation method of lithium ion battery positive pole material and lithium ion battery

A technology for lithium-ion batteries and cathode materials, which can be applied in battery electrodes, secondary batteries, circuits, etc., and can solve the problems of Mn material particle cracking and deterioration of cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the positive electrode material of lithium ion battery of an embodiment, comprises the following steps:

[0029] Step S110, mixing the nickel source, the manganese source and the aluminum source according to the stoichiometric ratio of each element in the chemical formula of the positive electrode material of the lithium ion battery, adding an organic solvent, and performing ball milling to obtain a mixture.

[0030] The chemical formula of lithium-ion battery cathode material is LiNi 0.5-y mn 1.5-2y al 2y o 4 , where 0<y≤0.3.

[0031] Preferably, the nickel source is selected from at least one of nickel chloride, nickel oxide, nickel sulfate, nickel nitrate and nickel acetate. Further, the nickel element in the nickel source is at least one of trivalent nickel and divalent nickel.

[0032] Preferably, the manganese source is selected from at least one of manganese chloride, manganese oxide, manganese sulfate, manganese nitrate and mangane...

Embodiment 1

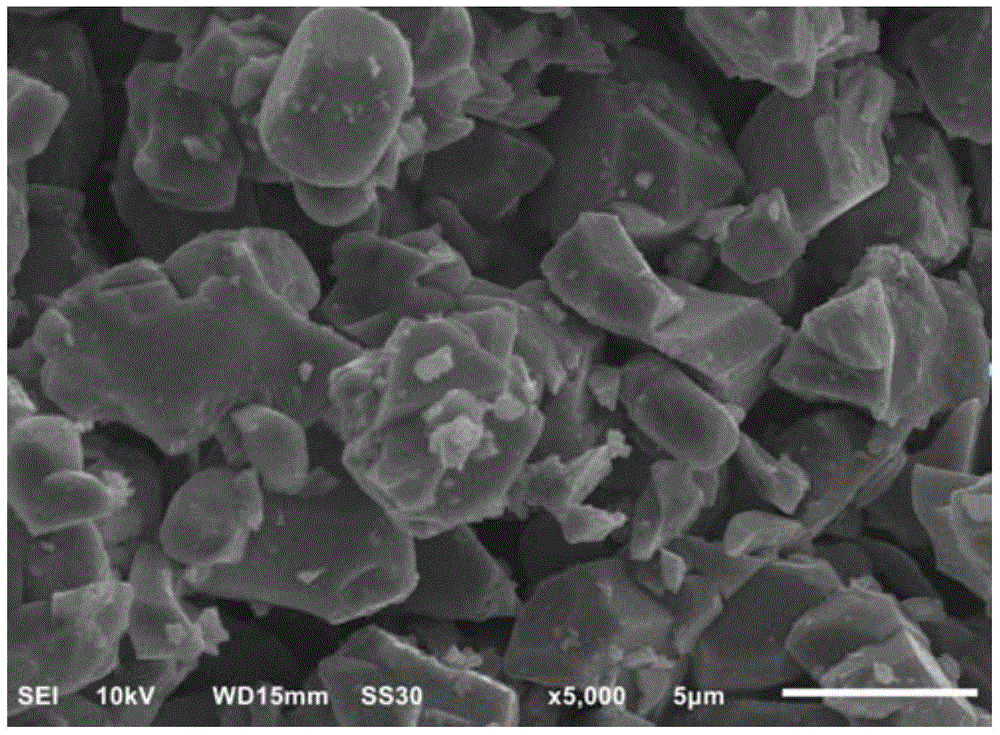

[0070] The chemical formula of the lithium-ion battery cathode material prepared in Example 1 is LiNi 0.5-y mn 1.5-2y al 2y o 4 , where y=0.3, that is, the chemical formula of the prepared lithium-ion battery cathode material is LiNi 0.2 mn 0.9 al 0.6 o 4 .

[0071] The preparation method of above-mentioned lithium-ion battery cathode material comprises the following steps:

[0072] (1) Weigh nickel nitrate hexahydrate, nickel nitrate tetrahydrate and aluminum hydroxide according to the ratio of element molar ratio Ni:Mn:Al=0.2:0.9:0.6 and put them into a ball mill jar, add acetone, the quality of acetone and nickel source Ratio is 0.2:1, with the speed of 650r / min, ball milling 10h to obtain the mixture;

[0073] (2) Transfer the mixture in step (1) to a muffle furnace, heat it to 700° C. at a heating rate of 10° C. / min in an air atmosphere, and calcine at a constant temperature for 10 hours;

[0074] (3) Then naturally cool to room temperature, take out the sample, ...

Embodiment 2

[0080] The chemical formula of the lithium-ion battery cathode material prepared in Example 2 is LiNi 0.5-y mn 1.5-2y al 2y o 4 , where y=0.25, that is, the chemical formula of the prepared lithium-ion battery cathode material is LiNi 0.25 mn 1 al 0.5 o 4 .

[0081] The preparation method of above-mentioned lithium-ion battery cathode material comprises the following steps:

[0082] (1) Weigh nickel sulfate hexahydrate, manganese sulfate tetrahydrate and aluminum chloride hexahydrate according to the ratio of element molar ratio Ni:Mn:Al=0.25:1:0.5 and put them into a ball mill jar, add suitable acetone, acetone and nickel The mass ratio of the source is 0.15:1, with the speed of 650r / min, ball milling 8h obtains the mixture;

[0083] (2) the mixture in the step (1) is transferred in the muffle furnace, and the oxygen flow rate is 18m 3 / h atmosphere, heated to 700°C at a heating rate of 10°C / min, and calcined at a constant temperature for 10h;

[0084] (3) Then natu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com