Nitric acid corrosion resistant titanium-based neutron absorbing material and preparation method thereof

A technology of absorbing material and nitric acid, which is applied in the field of nitric acid corrosion-resistant titanium-based neutron absorbing material and its preparation, can solve the problems of high radioactivity and strong corrosiveness, high difficulty in equipment maintenance, and personnel injured by radiation, and achieves strong absorption. effect of sub-capacity, good hot workability, good weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

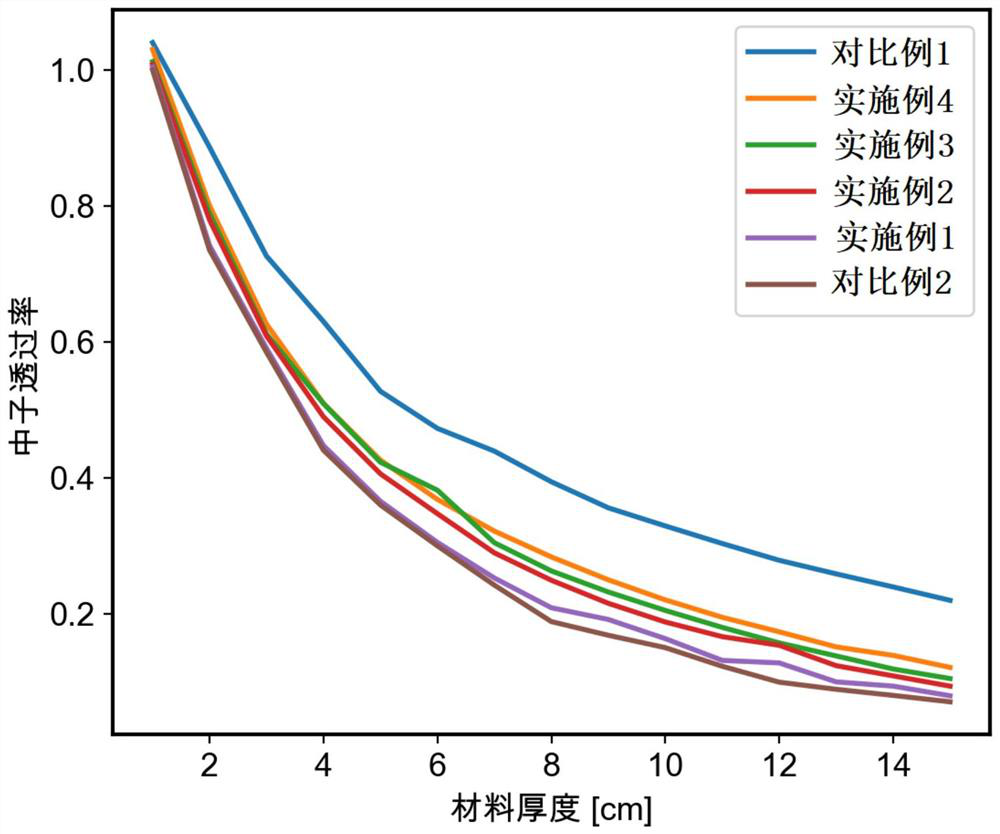

[0033] The nitric acid corrosion-resistant titanium-based neutron absorbing material of this embodiment is composed of the following components in mass content: Ta 6%, Gd 15%, and the balance is Ti and unavoidable impurities.

[0034] This embodiment includes the following steps;

[0035] Step 1. After mixing titanium-tantalum master alloy scraps, gadolinium scraps and titanium sponge, they are smelted to obtain titanium alloy ingots; the melting method is vacuum consumable arc melting; the amount of gadolinium scraps added is theoretically Increase by 30% on the basis of quantity;

[0036] Step 2, forging the titanium alloy ingot obtained in step 1 to obtain a titanium alloy forging; the forging process is: sequentially carry out billet forging, intermediate forging and finished product forging, wherein the temperature of billet forging is 1080°C, The temperature of the intermediate forging is 980°C, the firing times of the intermediate forging are 2 times, and the temperatu...

Embodiment 2

[0059] The nitric acid corrosion-resistant titanium-based neutron absorbing material of this embodiment is composed of the following components in mass content: Ta 6%, Gd 10%, and the balance is Ti and unavoidable impurities.

[0060] This embodiment includes the following steps;

[0061] Step 1: Melting titanium-tantalum master alloy scraps, gadolinium scraps and titanium sponge after mixing to obtain titanium alloy ingots; the smelting method is a non-consumable vacuum electric arc furnace melting method; the amount of gadolinium scraps added is theoretically Add 20% on the basis of the added amount;

[0062] Step 2. Forging the titanium alloy ingot obtained in step 1 to obtain a titanium alloy forging; the forging process is: sequentially carry out billet forging, intermediate forging and finished product forging, wherein the temperature of billet forging is 1060°C, The temperature of the intermediate forging is 950°C, the firing times of the intermediate forging are 3 tim...

Embodiment 3

[0067] The nitric acid corrosion-resistant titanium-based neutron absorbing material of this embodiment is composed of the following components in mass content: Ta 6%, Gd 5%, and the balance is Ti and unavoidable impurities.

[0068] This embodiment includes the following steps;

[0069] Step 1: Melting titanium-tantalum master alloy scraps, gadolinium scraps and titanium sponge after mixing to obtain titanium alloy ingots; the melting method is a cold hearth smelting method; the addition of the gadolinium scraps is within 15% increase on the basis;

[0070]Step 2, forging the titanium alloy ingot obtained in step 1 to obtain a titanium alloy forging; the forging process is: sequentially carry out blank forging, intermediate forging and finished product forging, wherein the temperature of blank forging is 1070°C, The temperature of the intermediate forging is 1000°C, the fire time of the intermediate forging is 1 time, and the temperature of the finished forging is 860°C; Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com