Preparation method of polycarbonate high-temperature-resistant degradation agent and polycarbonate composition

A polycarbonate, high temperature resistant technology, applied in the field of polycarbonate compositions, polycarbonate high temperature degradation agents, and preparation fields, can solve the problems of increasing production costs, poor high temperature degradation resistance of antioxidants, etc., and achieves easy operation. , The effect of post-processing purification is convenient and efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

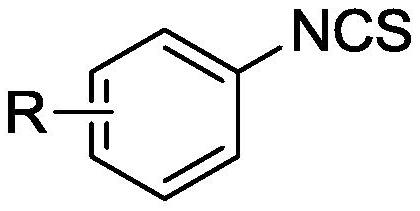

[0039] Acetonitrile (40ml) and phenyl isothiocyanate (2.70g, 20mmol) are added successively in the reactor that thermometer and reflux condenser are housed, one-shot adds indium trichloride (8.85g, 40mmol) in the reactor, will The temperature of the reaction system was raised to 80°C, the boiling point of acetonitrile, and refluxed. After the indium trichloride was completely dissolved, the reaction was refluxed for another 4 hours. The filtrate was obtained by filtration, and the solvent in the filtrate was evaporated by a rotary evaporator to obtain a crude product. The obtained crude product was recrystallized with ethyl acetate, and the white solid was filtered out with suction to obtain 2.62 g of polycarbonate anti-high temperature degradation agent A, with a yield of 97%. The reaction formula is as follows:

[0040]

[0041] 1 H NMR (CDCl 3,500MHz): δ9.23(s,1H),7.53-7.57(m,2H),8.23-8.33(m,1H),8.09-8.13(m,1H).

[0042] Then, take 12kg of polycarbonate powder and 0.1...

Embodiment 2

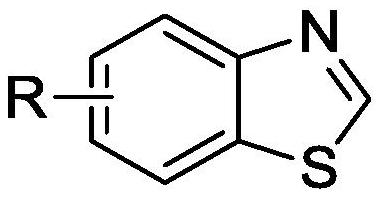

[0045] Toluene (40ml) and p-methylphenylisothiocyanate (2.98g, 20mmol) were added successively in the reactor equipped with a thermometer and a reflux condenser, and indium trichloride (6.64g, 30mmol) was added to the reactor at one time. ), the temperature of the reaction system was raised to 110°C, the boiling point of toluene, and refluxed. After the indium trichloride was completely dissolved, the reaction was refluxed for 4 hours, and the filtrate was filtered, and the solvent in the filtrate was evaporated by a rotary evaporator to obtain a crude product. The obtained crude product was recrystallized with ethyl acetate, and the white solid was filtered out with suction to obtain 2.80 g of polycarbonate anti-high temperature degradation agent B with a yield of 94%. The reaction formula is as follows:

[0046]

[0047] 1 H NMR (CDCl 3 ,500MHz): δ9.11(s,1H),7.89-8.02(m,1H),7.79(s,1H),7.21-7.35(s,1H),2.52(s,3H).

[0048] Then, take 12kg polycarbonate powder and 0.12g p...

Embodiment 3

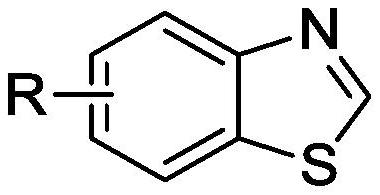

[0050] Chlorobenzene (40ml) and o-methyl phenylisothiocyanate (2.98g, 20mmol) are added successively in the reactor that thermometer and reflux condenser are housed, one-time adds indium trichloride (4.43g, 20mmol), the temperature of the reaction system was raised to 132°C, the boiling point of chlorobenzene, and refluxed. After the indium trichloride was completely dissolved, the reaction was refluxed for 3.5h, and the filtrate was filtered, and the solvent in the filtrate was evaporated by a rotary evaporator to obtain a crude product. The obtained crude product was recrystallized with ethyl acetate, and the white solid was filtered out with suction to obtain 2.68 g of polycarbonate anti-high temperature degradation agent C, with a yield of 90%. The reaction formula is as follows:

[0051]

[0052] 1 H NMR (CDCl 3 ,500MHz): δ9.17(s,1H),7.78-7.87(m,1H),7.30-7.47(m,1H),7.01-7.16(m,1H),2.02(s,3H).

[0053] Then, take 12kg polycarbonate powder, 0.12g polycarbonate anti-hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com