Purification method of high-purity tacrolimus

A technology of tacrolimus and purification method, which is applied in the field of biopharmaceutical engineering, can solve the problems of poor separation effect, low purification yield, high product cost, etc., and achieve the improvement of purity and yield, large amount of separation and preparation, and high selectivity separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

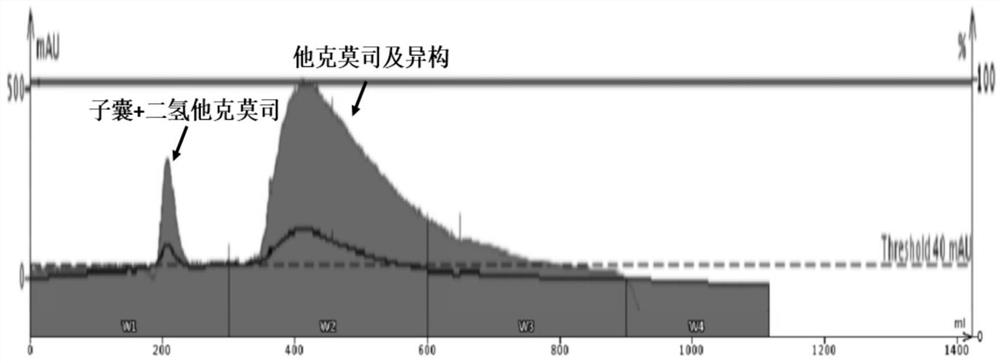

Method used

Image

Examples

Embodiment 1

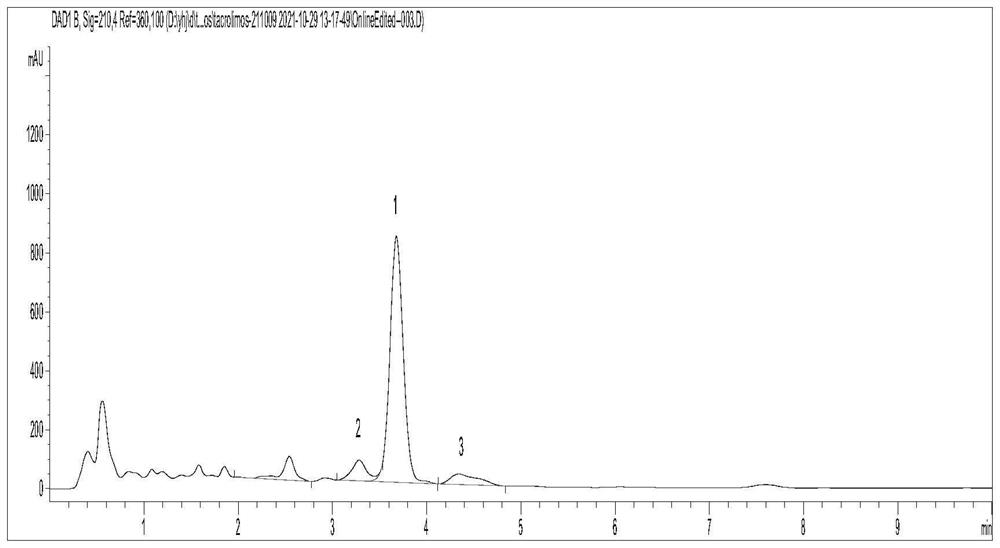

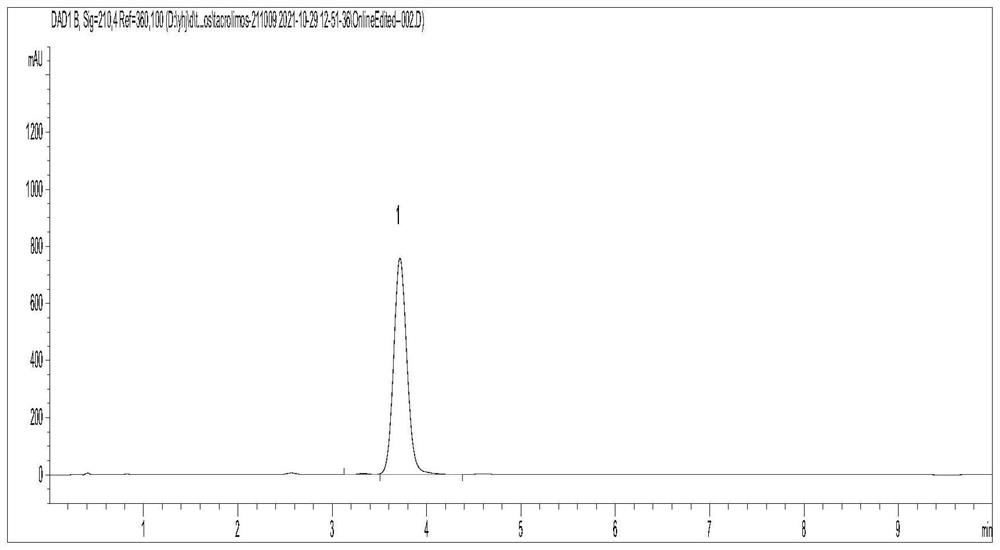

[0036] 20 g of the crude extract of tacrolimus was fully dissolved with 50 ml of acetone, and filtered. The chromatographic column is equipped with a silver nitrate-treated silica gel packing bound with 3-mercaptopropyl (particle size 40um, pore size ) 1.0L, the chromatographic column is pre-balanced with petroleum ether, the sample solution is adsorbed on the normal phase column, first eluted with petroleum ether for 3 times the column volume, and then with acetone / petroleum ether (1:5) mixed solution eluent isocratic Elution, control the elution flow rate 1.0BV / h, the eluate obtained by separation and purification is analyzed for purity by UHPLC method and the collected solution is determined, and the combined tacrolimus collected solution with a purity greater than 99% has a yield of 98.2% (yield =Pure product weight×purity / (crude extract loading weight×crude extract purity)). The collected liquid was concentrated to dryness, a small amount of acetone was saturated and di...

Embodiment 2

[0038] 50 g of the crude extract of tacrolimus was fully dissolved in 80 ml of butyl acetate, and filtered. The chromatographic column is equipped with silica gel packing (particle size 40um, pore size ) 3.0L, the chromatographic column is pre-balanced with petroleum ether, the sample solution is adsorbed on the normal phase column, first eluted with petroleum ether for 3 times the column volume, and then eluted with ethyl acetate / petroleum ether (1:3) mixture Isocratic elution, the elution flow rate was controlled at 1.0BV / h, the collected solution was determined by UHPLC method, and the collected solution of tacrolimus with a purity greater than 99% was combined, and the yield was 96.4%. The collected liquid was concentrated to dryness, a small amount of ethyl acetate was saturated and dissolved, filtered with suction, and allowed to stand for crystallization to obtain 42.8 g of pure tacrolimus.

Embodiment 3

[0040]20 g of the crude extract of tacrolimus was fully dissolved with 50 ml of acetone, and filtered. The chromatographic column is filled with rare earth ions Eu 3+ Treated bonded 2-mercaptobenzothiazole silica filler (particle size 40um, pore size ) 1.0L, the chromatographic column is pre-balanced with petroleum ether, the sample solution is adsorbed on the normal phase column, first eluted with petroleum ether for 3 times the column volume, and then with acetone / petroleum ether (1:5) mixed solution eluent isocratic For elution, the elution flow rate was controlled at 1.0 BV / h, and the collected solution was measured by UHPLC method, and the collected solution of tacrolimus with a purity greater than 99% was combined, and the yield was 93.4%. The collected solution was concentrated to dryness, a small amount of acetone was saturated and dissolved, filtered with suction, and allowed to stand for crystallization to obtain 16.8 g of pure tacrolimus.

[0041] The different...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com