Wear-resistant anti-adhesion coating as well as preparation method and application thereof

An anti-adhesion and coating technology, applied in the direction of coating, metal material coating process, process efficiency improvement, etc., can solve the problem that the coating structure is easily damaged by sharp objects, polymer materials adhere to the roller surface, and affect the product Problems such as processing quality, to achieve the effect of reducing unstable pores, excellent densification speed, and ensuring densification and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A wear-resistant anti-adhesion coating, each component and its corresponding weight are as shown in Table 1, and are obtained by the following preparation method:

[0045] Put silicon carbide powder, sintering aid, binder, calcium aluminate titanate powder, titanium dioxide powder and zirconium silicide into the ball mill according to the corresponding parts by weight, and use water as the ball milling liquid to carry out wet ball milling and mixing for 3 hours to obtain wear-resistant and anti-corrosion powder. Adhesive paint; wherein the sintering aid is boron carbide; the binder is epoxy resin.

Embodiment 2-6

[0047] A wear-resistant anti-adhesion coating, the difference from Example 1 is that each component and its corresponding weight are shown in Table 1.

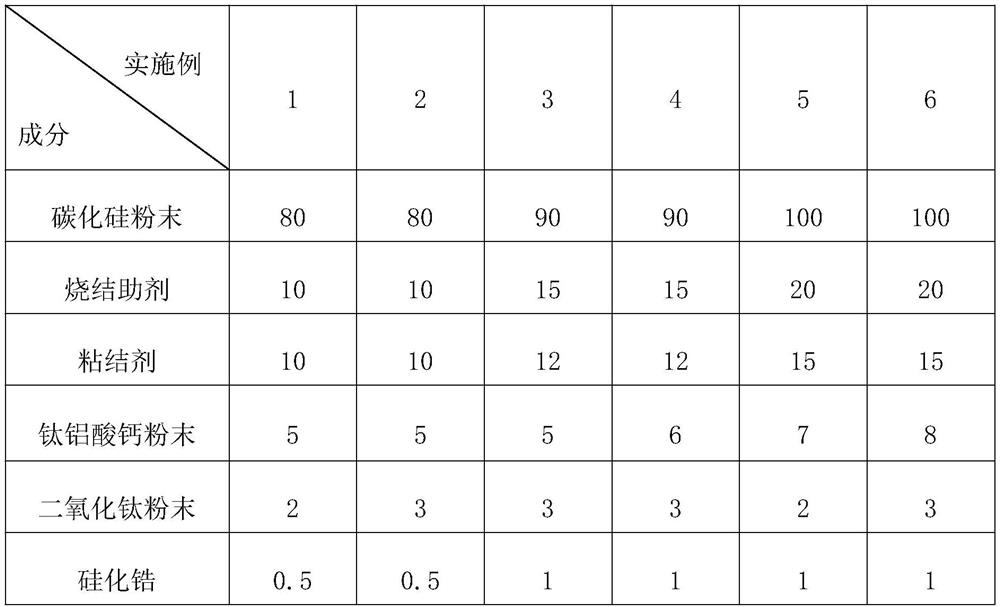

[0048] Table 1: Each component and its weight (kg) among the embodiment 1-6

[0049]

Embodiment 7

[0051] A wear-resistant and anti-adhesion coating, except that the sintering aid is zinc fluorosilicate, the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com