Nickel-based positive electrode material of lithium secondary battery and preparation method of nickel-based positive electrode material

A lithium secondary battery and positive electrode material technology, applied in secondary batteries, battery electrodes, positive electrodes, etc., can solve the problems of high manufacturing cost, complicated manufacturing process, poor high-temperature cycle performance and safety performance, and improve the crystal structure The effect of stability, simple manufacturing process and equipment, excellent cycle and high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

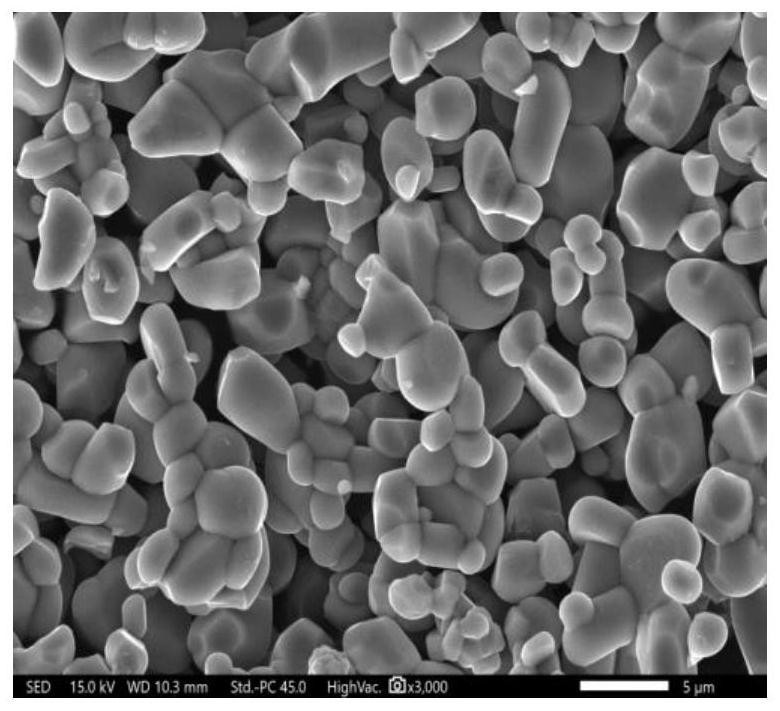

[0030] The nickel-based positive electrode material of this embodiment is

[0031] Li 1.03 (Ni 0.93 co 0.04 mn 0.02 al 0.01 ) 0.998 Mo 0.002 o 2 ·(LiSiAlWO 7 ) 0.001 The preparation method, concrete steps are as follows:

[0032] (1) Configure nickel chloride, cobalt chloride, manganese chloride, and aluminum chloride into a 2.0mol / L mixed salt solution according to the molar ratio of Ni:Co:Mn:Al=0.93:0.04:0.02:0.01. The solution is metered and sprayed from the top of the roasting furnace, and the spray reaction gas enters from the bottom of the roasting furnace through external preheating. By controlling the roasting temperature to 900°C, the spray gas flow rate to 60L / min, the spray gas oxygen concentration to 95%, and the spray gas heating temperature The temperature is 300℃, the spray gas pressure is 0.6Mpa, the nozzle diameter is 10mm and other parameters are used for high-temperature spray roasting reaction. The two rapid high-temperature hydrolysis reactions p...

Embodiment 2

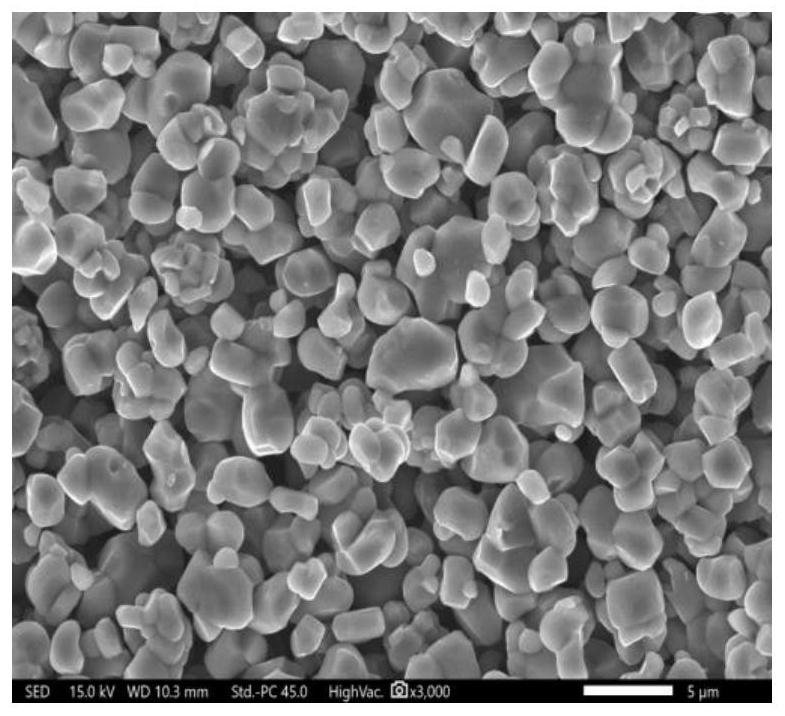

[0038] The nickel-based cathode material of this embodiment is Li 1.05 (Ni 0.93 mn 0.06 al 0.01 ) 0.998 Ba 0.002 o 2 ·(LiSiAlWO 7 ) 0.001 The preparation method, concrete steps are as follows:

[0039] (1) Configure nickel chloride, manganese chloride, and aluminum chloride into a 2.0mol / L mixed salt solution according to the molar ratio of Ni:Mn:Al=0.93:0.06:0.01, and spray the mixed salt solution from the top of the roasting furnace At the same time, the spray reaction gas enters from the bottom of the roasting furnace through external preheating. By controlling the roasting temperature to 915°C, the spray gas flow rate to 70L / min, the spray gas oxygen concentration to 97%, the spray gas temperature to 320°C, and the spray gas pressure to 0.7 Mpa, nozzle diameter 13mm and other parameters for high-temperature spray roasting reaction, the rapid high-temperature hydrolysis reaction of the two produces metal oxides that settle at the bottom of the roaster and are discha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com