Composite nanoparticle as well as preparation method and application thereof

A nanoparticle, hydrolysis and condensation technology, applied in the direction of pharmaceutical formulations, drug combinations, medical preparations of non-active ingredients, etc., can solve the problems of drug delivery systems without reducing ATO, and achieve good acid-responsive drug release ability and strong immune activation effect, the effect of avoiding early leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

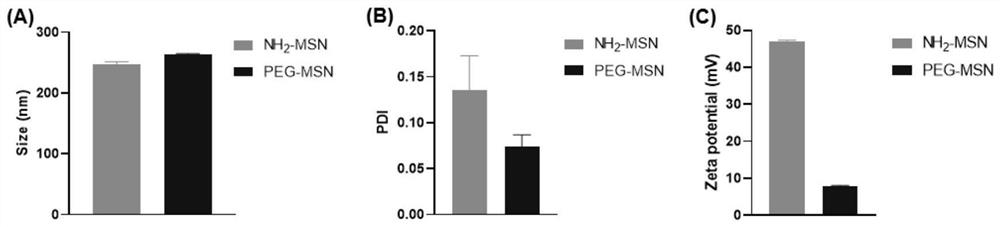

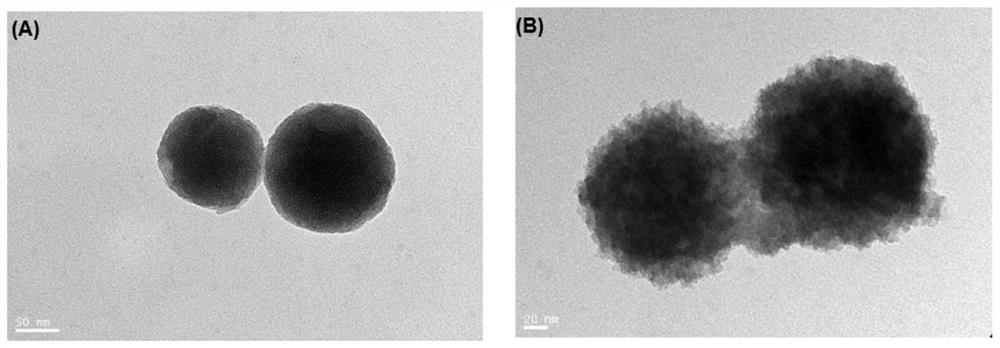

[0084] Example 1 Aminated mesoporous silica nanoparticles (NH 2 -MSN) preparation

[0085] In this example, the effect of the dosage of silicon source TEOS and silane coupling agent APTES on aminated mesoporous silica nanoparticles (NH 2 -MSN) particle size, PDI and the effect of surface potential. Specific steps are as follows:

[0086] Preparation of CTAB solution: Weigh 0.1 g of CTAB powder and dissolve it in 48 mL of ultrapure water, heat and stir it in an oil bath at 50° C. to dissolve, to prepare a CTAB solution with a concentration of 0.055 mM.

[0087]When the temperature of 48 mL of 0.055 mM CTAB solution rose to 70 °C, the mixture of TEOS and APTES was rapidly added dropwise thereto, and the reaction was carried out at 80 °C for 2 h under stirring conditions. After the reaction, cooled, centrifuged to remove the supernatant, collected the bottom precipitate, and dispersed it in acidic ethanol ((EtOH:HCL)=100:1(v / v)) containing concentrated hydrochloric acid (37% b...

Embodiment 2

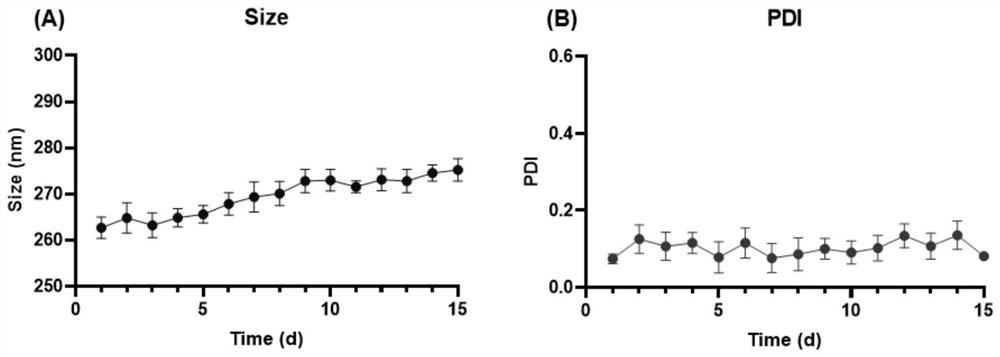

[0093] Example 2 Preparation of composite nanoparticles (PEG-MSN@ATO)

[0094] In this example, the aminated mesoporous silica nanoparticles (NH 2 -MSN) supported arsenic trioxide to obtain NH 2 -MSN@ATO followed by methoxypolyethylene glycol formaldehyde (mPEG-CHO) with NH 2 -MSN@ATO reaction to obtain composite nanoparticles (PEG-MSN@ATO); the aminated mesoporous silica nanoparticles (NH 2 -MSN) reacts with methoxy polyethylene glycol formaldehyde (mPEG-CHO) to obtain polyethylene glycol modified mesoporous silica nanoparticles (PEG-MSN), and the specific steps are as follows:

[0095] 1. Preparation of composite nanoparticles (PEG-MSN@ATO)

[0096] (1) Preparation of ATO solution: Weigh a certain amount of ATO powder and dissolve it in a NaOH solution with a pH value of 12. After the ATO is completely dissolved, adjust the pH to neutrality with concentrated hydrochloric acid, and then add ultrapure water to adjust the ATO solution to a certain value. volume so that the ...

Embodiment 3

[0107] Example 3 Detection of drug loading and encapsulation efficiency of composite nanoparticles (PEG-MSN@ATO)

[0108] In this example, the effects of different concentrations of ATO on drug loading and encapsulation efficiency were investigated, and the preparation method of PEG-MSN@ATO was the same as that in Example 2. It includes the following steps:

[0109] (1) Collection of supernatant: the supernatant A obtained in step (2) in Example 2 and the supernatant B obtained in (3) were combined and mixed, and the volume was precisely measured, and after the ultrapure water was diluted several times , take 10mL through a 0.22μm filter to obtain a filtrate.

[0110] (2) ICP-AES detection: get the filtrate of step (1) in the present embodiment of 5mL to detect the As concentration wherein with an inductively coupled plasma emission spectrometer, further convert into the content of free ATO wherein, calculate the encapsulation efficiency according to the formula ( Encapsulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com