Metal ion-organic ligand flotation reagent as well as preparation method and application thereof

A technology of organic ligands and metal ions, which is applied in the fields of flotation reagents and their preparation, metal ion-organic ligand flotation reagents and their preparation, which can solve the collection of difficult collectors, and it is difficult to reduce sulfide ore residues, etc. problem, to achieve the effect of simple process, convenient large-scale industrial production and stable reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

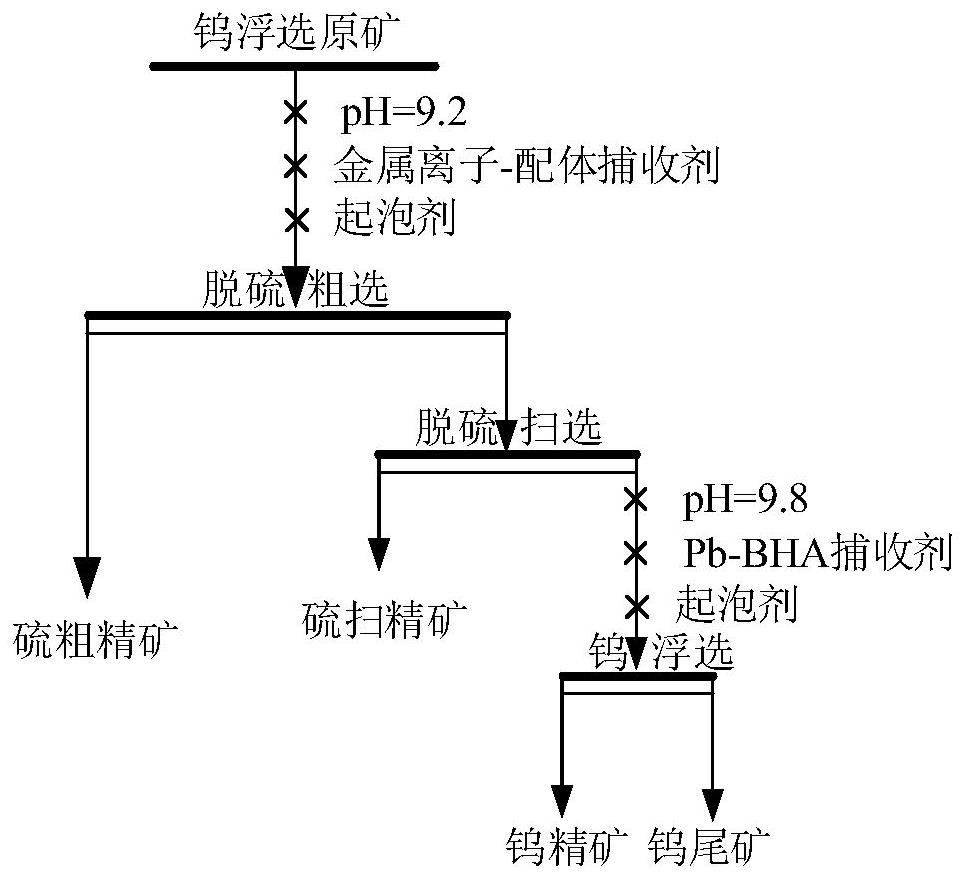

Embodiment 1

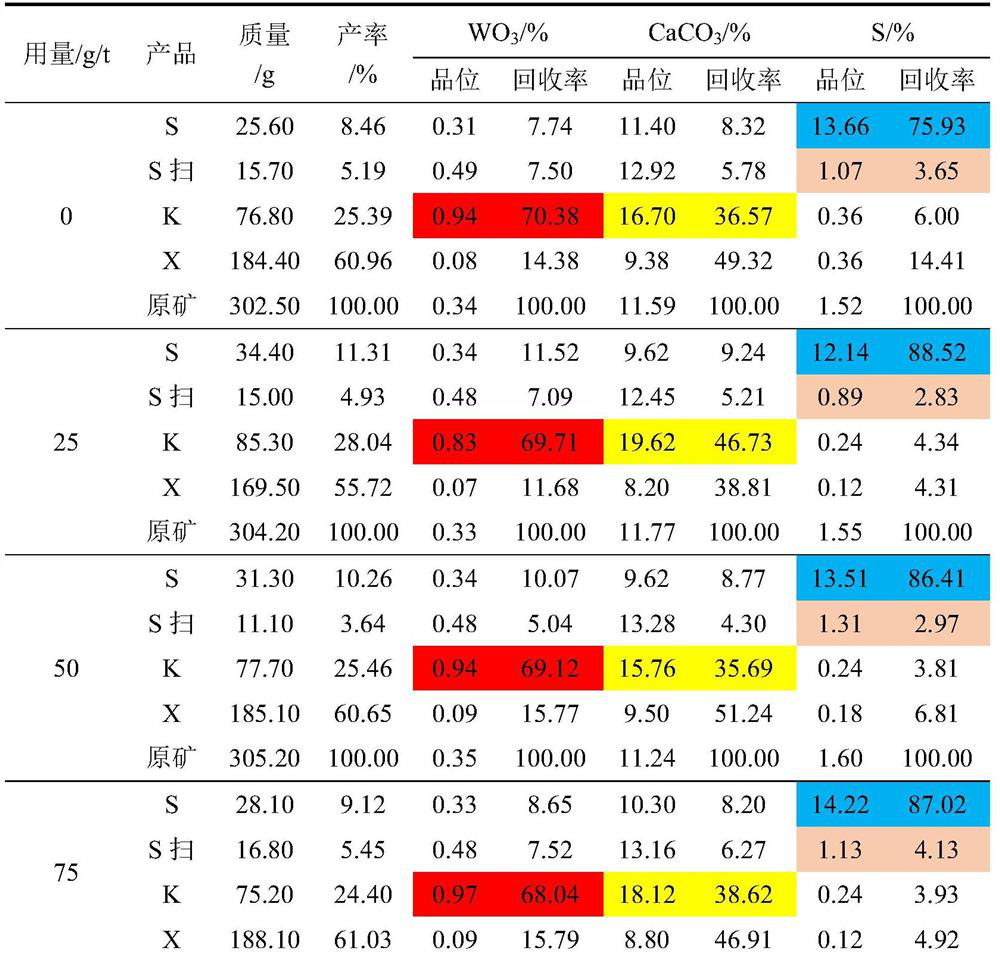

[0032] Taking a polymetal in Chenzhou, Hunan Province as the research object, the effect of the dosage of Cu-thiocarbamide flotation reagents on the flotation index in the front stage of tungsten selection was investigated. The flow chart is as follows, the desulfurization adopts a rough sweep process, the rough selection pH=9.2, and the collector is Cu-sulfur ammonium ester collector (Cu 2+ It is prepared by reacting with thiourethane at a mass ratio of 2:1 at 50°C and pH=9.0 for 30 minutes, and is purified by carrier adsorption); sulfur sweeping is blank flotation without flotation reagents. The tungsten selection process is a rough selection, using 500g / t lead benzhydroxamate (Pb-BHA) collector, pH=9.8. It can be seen from the results that with the increase of the ligand collector, the desulfurization amount and desulfurization efficiency are both improved, especially the recovery rate can be increased by about 10%. At the same time, this agent basically has no effect on the...

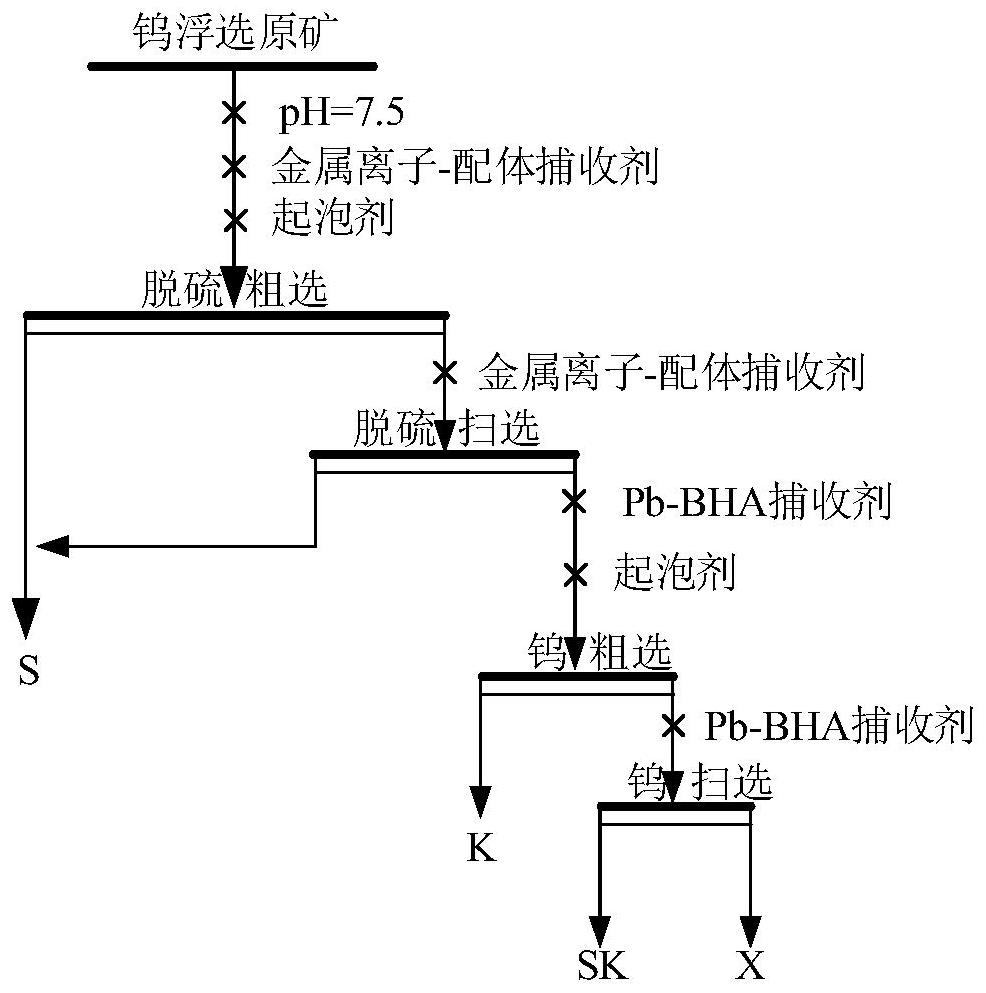

Embodiment 2

[0037] A tungsten polymetallic field ore in Hunan was selected to carry out the step-by-step release test of Pb-ethyl sulfide enhanced desulfurization. Preparation conditions: Pb 2+ React with ethion at a mass ratio of 1:1 at 45°C and pH=9.5 for 40 min; flotation conditions: pH=9.0, 100g / t Pb-ethion. The results are shown below. It can be seen from the results that the desulfurization flotation has the highest grade and recovery rate in the first 1 minute; Pb-ethyl sulfide can strengthen the desulfurization flotation and improve the flotation efficiency of sulfide ore; Pb-ethyl sulfide can reduce the tungsten separation section after the activated desulfurization. The sulfur content has no effect on the flotation of tungsten.

[0038] Table 2 The results of the enhanced desulfurization test of a tungsten polymetallic ore in Hunan

[0039]

Embodiment 3

[0041] Cu-Ethylnitrogen (Cu 2+ With ethyl sulfide nitrogen in a ratio of 1.5:1 by mass, react at 55 ° C and pH = 8.5 for 50 min) to strengthen the industrial experimental research on desulfurization. The S grade in the tungsten concentrate product before and after the addition was monitored by the shift sample, and the results are as follows. It can be seen that the S content in the tungsten concentrate is significantly reduced after the addition of Cu-ethyl sulfide, and the grade of the tungsten concentrate is improved to a certain extent.

[0042] Table 3 The results of the industrial test of enhanced desulfurization in Shizhuyuan

[0043]

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com