Optimization design method for structural parameters of solid rocket engine jet pipe

An engine nozzle, solid rocket technology, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve problems such as calculation error, slippage between adhesive layers, thermal stress extreme value position deviation, etc. Safety and reliability, avoiding uncertain problems, reducing the effect of thermal damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

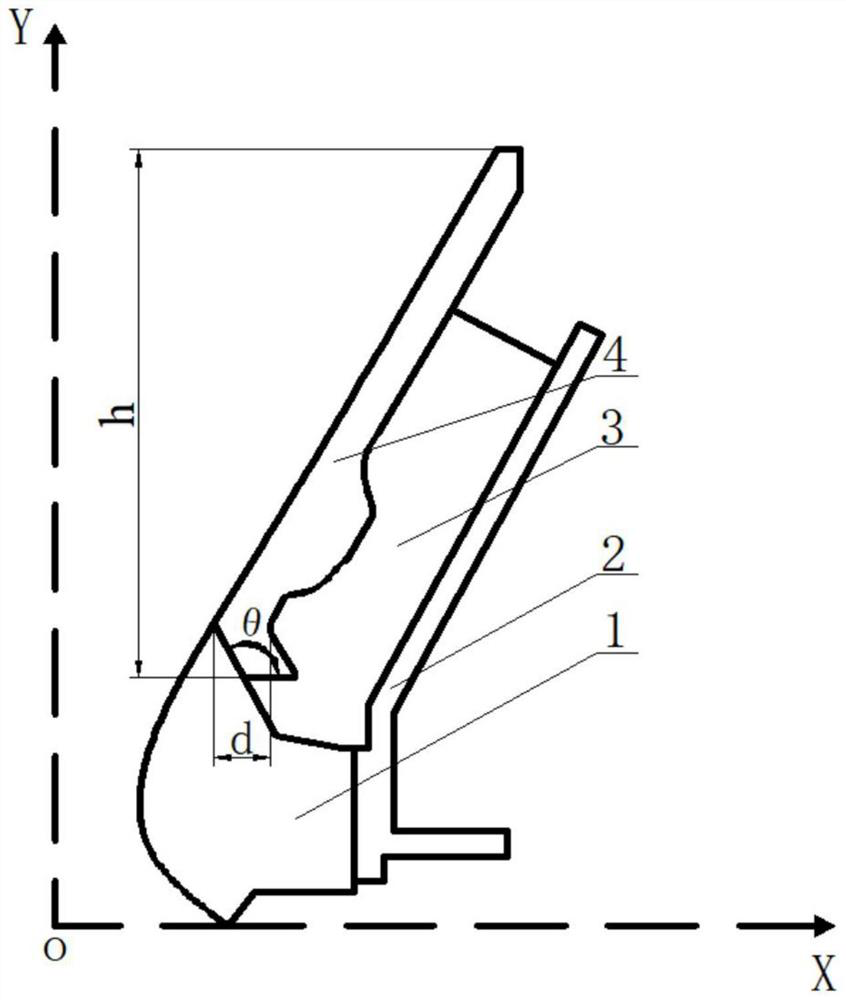

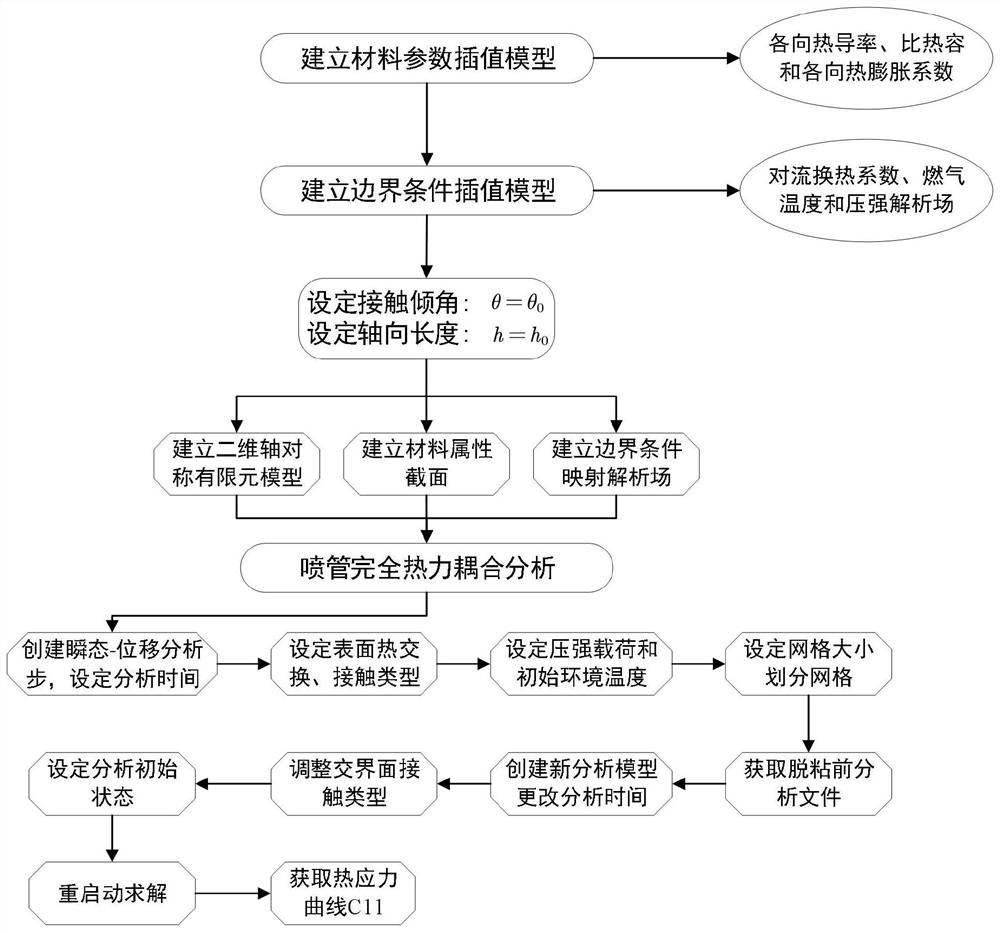

[0059] see figure 1 , in this embodiment, the solid rocket motor nozzle is composed of a throat lining 1, an outer casing 2, a thermal insulation layer 3 and an expansion section 4; in a method for optimizing structural parameters of a solid rocket motor nozzle, the optimally designed structure The parameters include: the contact inclination angle θ of the expansion section 4 and the throat liner 1, the axial length h of the expansion section 4 and the radial thickness d at the barb of the expansion section 4;

[0060] S1: Establish the material parameter interpolation model of the solid rocket motor nozzle according to the piecewise cubic Hermite interpolation method shown in formula (1), and obtain the material parameter value sequence:

[0061]

[0062] In formula (1), m represents the type of material parameter, the values are 1, 2, and 3, respectively, corresponding to thermal conductivity, specific heat capacity and thermal expansion coefficient, n represents the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com