Double-protein spoon-eating type fermented milk and preparation method thereof

A technology of fermented milk and double protein, which is applied in the direction of bacteria and lactobacillus used in dairy products and food preparation, can solve the problems of cumbersome preparation method of yogurt, increased product microbial risk, negative changes in product flavor and taste, etc. The effect of whey precipitation, unique milk flavor and stable product state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

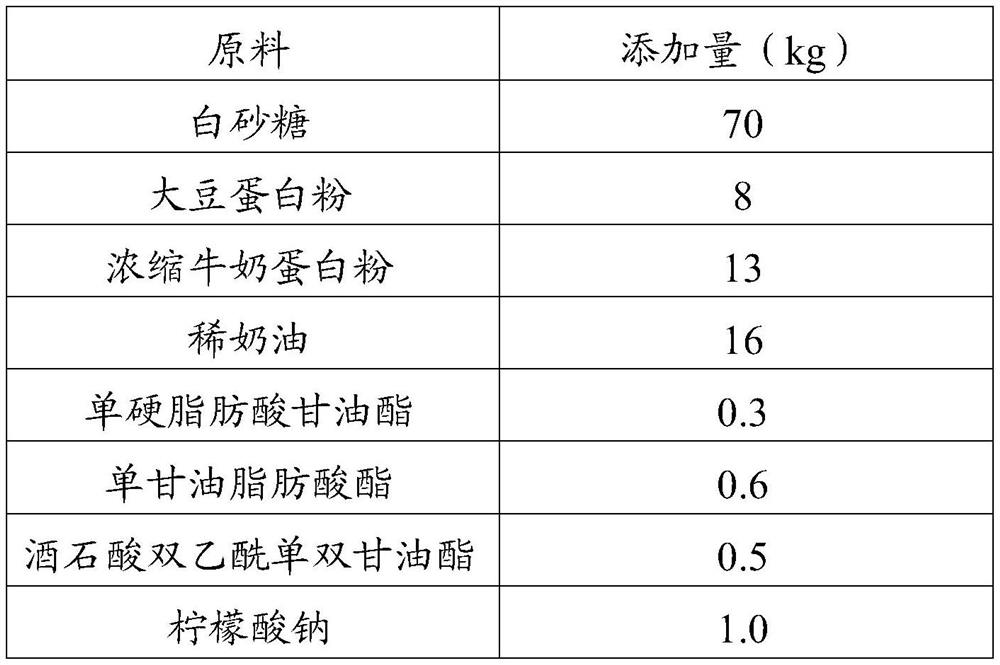

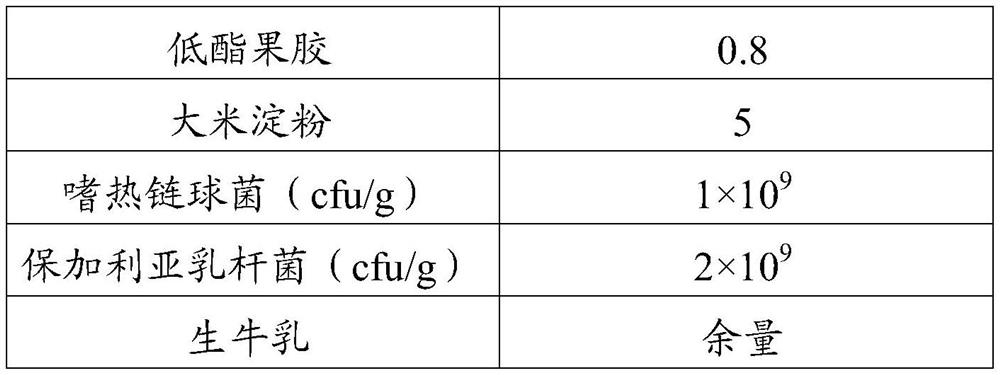

[0030] 1. Formula (contained in every 1000kg of raw materials)

[0031]

[0032]

[0033] 2. Preparation method:

[0034] (1) the white granulated sugar of 35kg, low-fat pectin and monostearic fatty acid glyceride, monoglyceride fatty acid ester, tartrate diacetyl mono-diglyceride are mixed, drop into the raw milk that is warming up to 75 ℃, circulate 20min and obtain batching milk.

[0035] (2) Cool the ingredient milk of step (1) to 55°C.

[0036] (3) Mixing the remaining amount of white granulated sugar with the remaining stabilizer, concentrated milk protein powder, soybean protein powder and sodium citrate to obtain ingredients.

[0037] (4) Put the ingredients obtained by mixing the cream and step (3) into the ingredient milk after cooling in step (2), and circulate for 30min.

[0038] (5) The ingredient milk of step (4) is reheated to 60° C., degassed and homogenized, and secondary homogenization is adopted, and the secondary pressure / total pressure is 30Bar / 18...

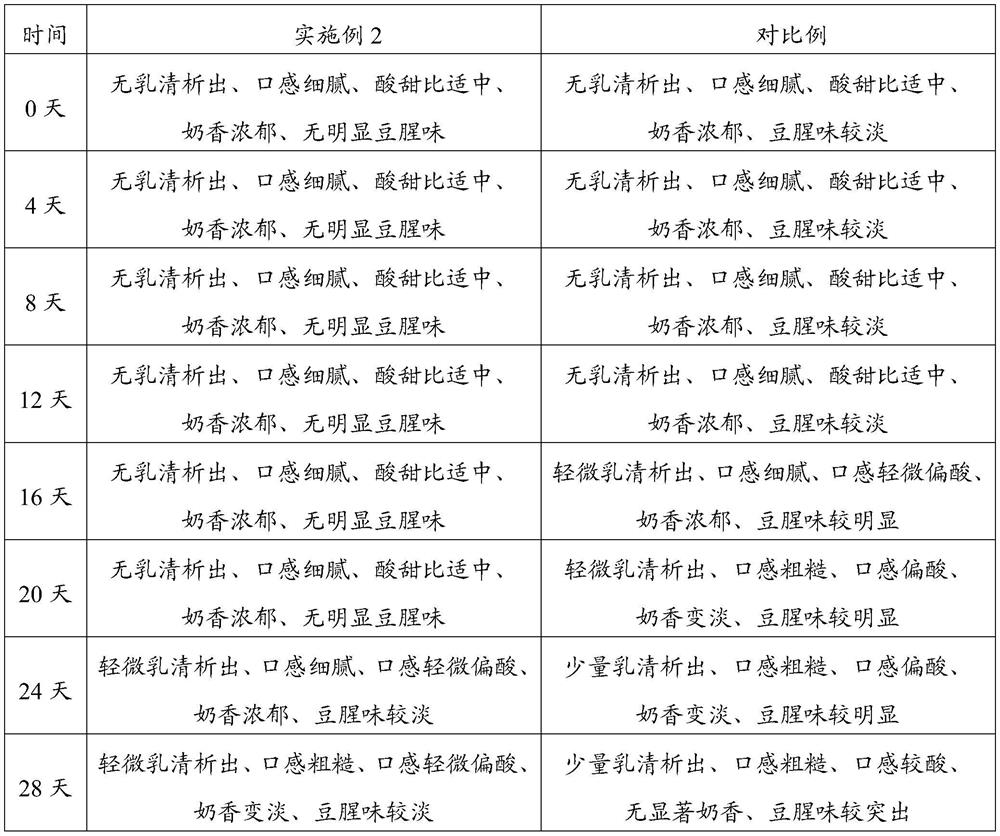

Embodiment 2

[0044] 1. Formula (contained in every 1000kg of raw materials)

[0045] raw material Addition amount (kg) White sugar 75 soy protein powder 8 Concentrated Milk Protein Powder 13 cream 11.5 Glyceryl monostearate 0.2 Diacetyl mono-diglyceride tartrate 0.4 Sodium citrate 1.3 low ester pectin 0.7 rice starch 5 Streptococcus thermophilus (cfu / g) 1.5×10 9

Lactobacillus bulgaricus (cfu / g) 2×10 9

raw milk margin

[0046] 2. Preparation method:

[0047] (1) 37.5kg of white granulated sugar, low-fat pectin, monostearic fatty acid glyceride and tartrate diacetyl mono-diglyceride are mixed, put into the raw milk that is warming up to 72 ° C, and circulate 25min to obtain ingredient milk.

[0048] (2) Cool the ingredient milk of step (1) to 53°C.

[0049] (3) Mixing the remaining amount of white granulated sugar with the remaining stabilizer, concentrated milk protein powder, soybean protein powd...

Embodiment 3

[0057] 1. Formula (contained in every 1000kg of raw materials)

[0058] raw material Addition amount (kg) White sugar 65 soy protein powder 8 Concentrated Milk Protein Powder 13 cream 23 monoglyceride fatty acid ester 0.6 Diacetyl mono-diglyceride tartrate 0.8 Sodium citrate 0.8 low ester pectin 0.8 rice starch 5 Streptococcus thermophilus (cfu / g) 1×10 9

Lactobacillus bulgaricus (cfu / g) 1.5×10 9

raw milk margin

[0059] (1) 32.5kg of white granulated sugar, low-fat pectin, monostearic fatty acid glyceride and tartrate diacetyl mono-diglyceride are mixed, put into the raw milk that is warming up to 75 ℃, circulate 25min to obtain ingredient milk.

[0060](2) Cool the ingredient milk of step (1) to 58°C.

[0061] (3) Mixing the remaining amount of white granulated sugar with the remaining stabilizer, concentrated milk protein powder, soybean protein powder and sodium citrate to obtain i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com