High-temperature gel channeling sealing agent as well as preparation method and application thereof

A technology of high temperature resistant gel and sealing and channeling agent, which is applied in the field of oil production, can solve the problems of plugging and channeling agent sedimentation at the bottom of the well and block the wellbore, and achieves the effects of controllable plugging strength, low initial viscosity and good suspension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

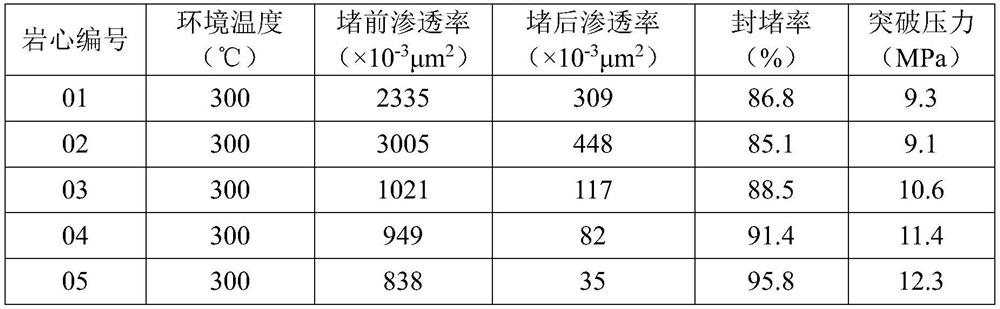

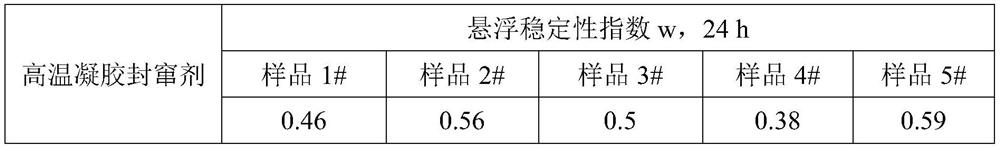

Examples

Embodiment 1

[0030] The present embodiment provides a high-temperature gel sealing and channeling agent. In mass percentage, the raw materials for preparing the high-temperature gel sealing and channeling agent include:

[0031] 6% mineral powder;

[0033] 0.3% glycerol polyoxyethylene ether cocoate;

[0034] 0.2% calcium lignosulfonate;

[0035] 0.25% carbon black;

[0036] 0.8% fly ash;

[0037] 0.016% sodium carbonate;

[0038] 0.01% β-naphthalene sulfonate formaldehyde condensate;

[0039] 0.006% ethylene-vinyl acetate copolymer;

[0040] 0.007% tetradecyldimethylbenzylammonium chloride

[0041] balance of water.

[0042] The specific preparation process is:

[0043] (1) successively adding mineral powder, sodium bentonite, glycerol polyoxyethylene ether cocoate, calcium lignosulfonate, carbon black, fly ash and sodium carbonate components into a liquid dispensing tank containing an appropriate amount of water, At room temperature, stir for 25 mi...

Embodiment 2

[0070] The present embodiment provides a high-temperature gel sealing and channeling agent. In mass percentage, the raw materials for preparing the high-temperature gel sealing and channeling agent include:

[0071] 9% mineral powder;

[0072] 4% sodium bentonite;

[0073] 0.5% glycerol polyoxyethylene ether cocoate;

[0074] 0.3% calcium lignosulfonate;

[0075] 0.35% carbon black;

[0076] 1.2% fly ash;

[0077] 0.02% sodium carbonate;

[0078] 0.012% β-naphthalene sulfonate formaldehyde condensate;

[0079] 0.008% ethylene-vinyl acetate copolymer;

[0080] 0.01% tetradecyldimethylbenzylammonium chloride

[0081] balance of water.

[0082] The specific preparation process is:

[0083] (1) successively adding mineral powder, sodium bentonite, glycerol polyoxyethylene ether cocoate, calcium lignosulfonate, carbon black, fly ash and sodium carbonate components into a liquid dispensing tank containing an appropriate amount of water, At room temperature, stir for 30 min...

Embodiment 3

[0112] The high temperature gel sealing and channeling agent prepared in Example 2 was applied to profile control and channeling sealing of huff and puff wells in heavy oil reservoirs.

[0113] Specifically, taking Well Du H5, a production well in Block Du 813 of Liaohe Oilfield, as an example, the well mainly has problems such as serious steam channeling and high water cut. At the same time, the casing of the wellbore has become serious, and conventional production stimulation control measures cannot be carried out, resulting in shut-in. In order to restore the productivity of the well, high temperature profile control and channeling sealing were implemented for the well.

[0114] The specific construction process includes: the dosage of high temperature gel sealing channeling agent is 1065m 3 , the displacement is 7.5m 3 / h, the initial injection construction pressure is 5.2MPa, the construction pressure rises slowly during the whole process, and the construction end pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com