Sponge-supported porphyrin covalent organic framework integral material as well as preparation method and application thereof

A covalent organic framework, monolithic material technology, applied in separation methods, material excitation analysis, chemical instruments and methods, etc., can solve the problems of poor Cd2+ affinity, hindering the large-scale practical application of adsorption materials, slow adsorption kinetics, etc. Excellent physical and chemical stability, short adsorption equilibrium time, fast adsorption kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for synthesizing a sponge-supported porphyrin covalent organic framework material, comprising the steps of:

[0042] A polyurethane sponge (50 mg) was immersed in a 0.1 mol / L dopamine solution (Tris-HCl buffer, pH=8.5), and after magnetic stirring for 24 hours, the sponge was taken out and vacuum-dried.

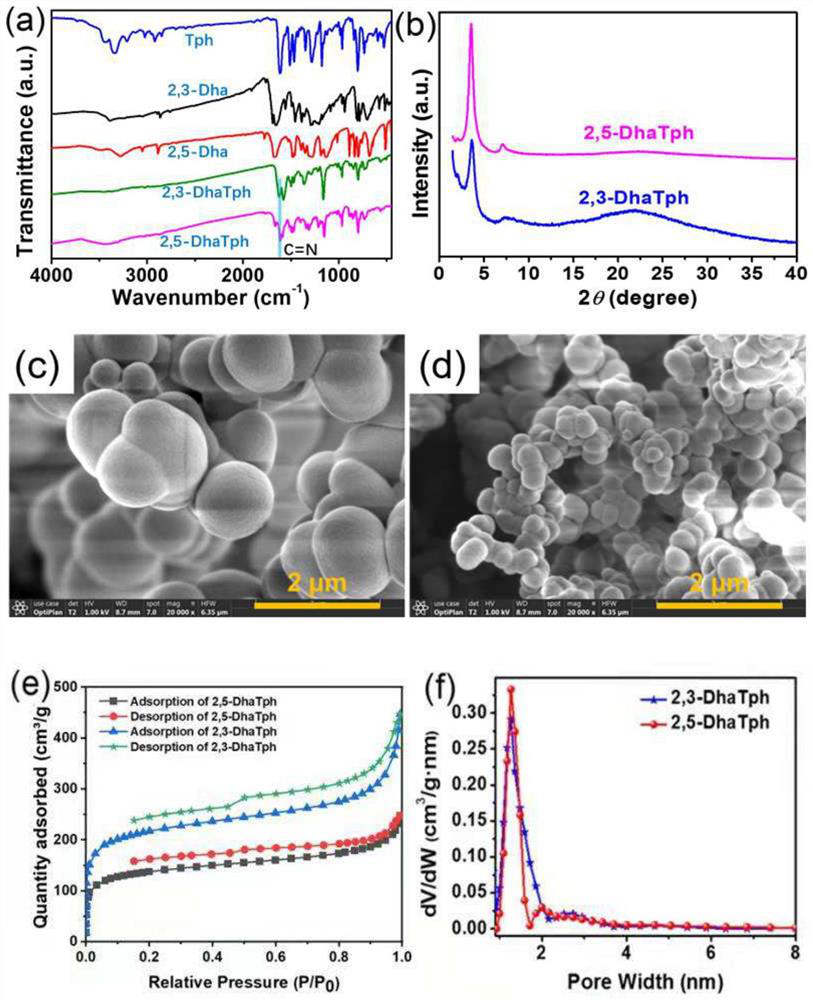

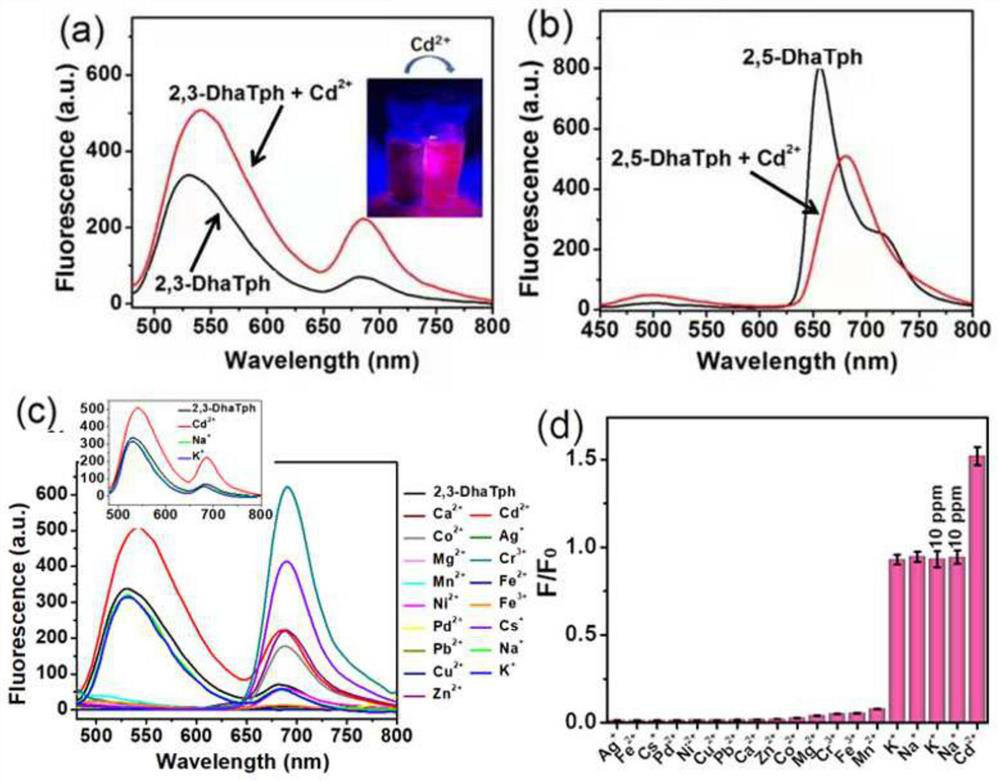

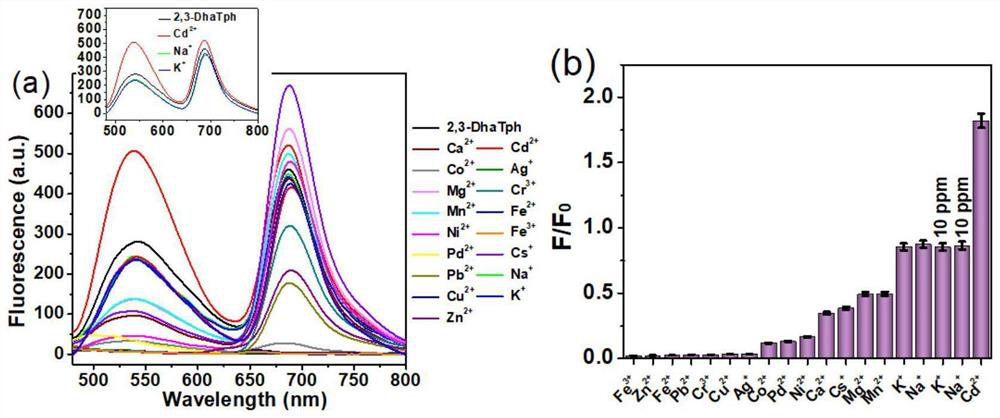

[0043] Starting with meso-tetrakis(4-aminophenyl)porphyrin (Tph) (67.5 mg, 0.1 mmol) and 2,3-dihydroxyterephthalaldehyde (2,3-Dha) (33.2 mg, 0.2 mmol) The starting materials were mixed in a 20 mL reaction vessel with o-dichlorobenzene (6 mL) and n-butanol (6 mL) as solvent and glacial acetic acid solution (6 M, 1 mL) as catalyst. The mixture was sonicated for 5 minutes. The treated dry sponge was added, then the reaction vessel was sealed and heated at 120°C for 3 days. After cooling to room temperature, the precipitate of the crude product was obtained by filtration. The precipitate was washed with tetrahydrofuran in a Soxhlet extractor for 12 hours, washed...

Embodiment 2

[0045] A method for synthesizing a sponge-supported porphyrin covalent organic framework material, comprising the steps of:

[0046] A polyurethane sponge (50 mg) was immersed in a 0.1 mol / L dopamine solution (Tris-HCl buffer, pH=8.5), and after magnetic stirring for 24 hours, the sponge was taken out and vacuum-dried.

[0047] Starting with meso-tetrakis(4-aminophenyl)porphyrin (Tph) (67.5 mg, 0.1 mmol) and 2,5-dihydroxyterephthalaldehyde (2,5-Dha) (33.2 mg, 0.2 mmol) The starting materials were mixed in a 20 mL reaction vessel with o-dichlorobenzene (6 mL) and n-butanol (6 mL) as solvent and glacial acetic acid solution (6 M, 1 mL) as catalyst. The mixture was sonicated for 5 minutes. The treated dry sponge was added, then the reaction vessel was sealed and heated at 120°C for 3 days. After cooling to room temperature, the precipitate of the crude product was obtained by filtration. The precipitate was washed with tetrahydrofuran in a Soxhlet extractor for 12 hours, washed...

Embodiment 3

[0049] The synthetic method of 2,3-DhaTph comprises the following steps:

[0050] Tph (67.5 mg, 0.1 mmol), 2,3-Dha (33.2 mg, 0.2 mmol), o-dichlorobenzene (6 mL), n-butanol (6 mL) and aqueous glacial acetic acid (6 M, 1 mL) in a 20 mL Mix in reaction vessel. The mixture was sonicated for 5 minutes. Then, the reaction vessel was sealed and heated at 120°C for 3 days. After cooling to room temperature, a precipitate of crude product was obtained by filtration. The precipitate was washed in a Soxhlet extractor with tetrahydrofuran for 12 hours, dichloromethane for 12 hours, and then dried at 60°C for 5 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com