A kind of preparation method of amine functionalized mesoporous γ-al2o3 adsorbent

An amine-based function, adsorbent technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of poor acid and alkali resistance, harsh conditions, toxic prices, etc., and achieve adsorption kinetics. The effect of fast, mild dipping conditions and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

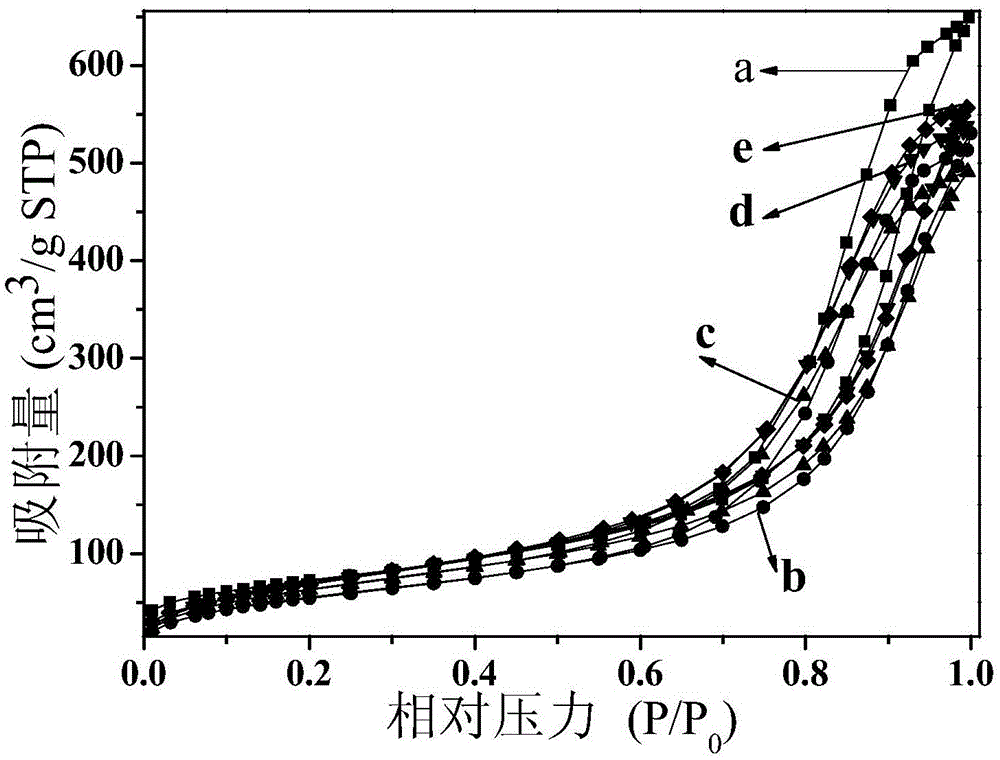

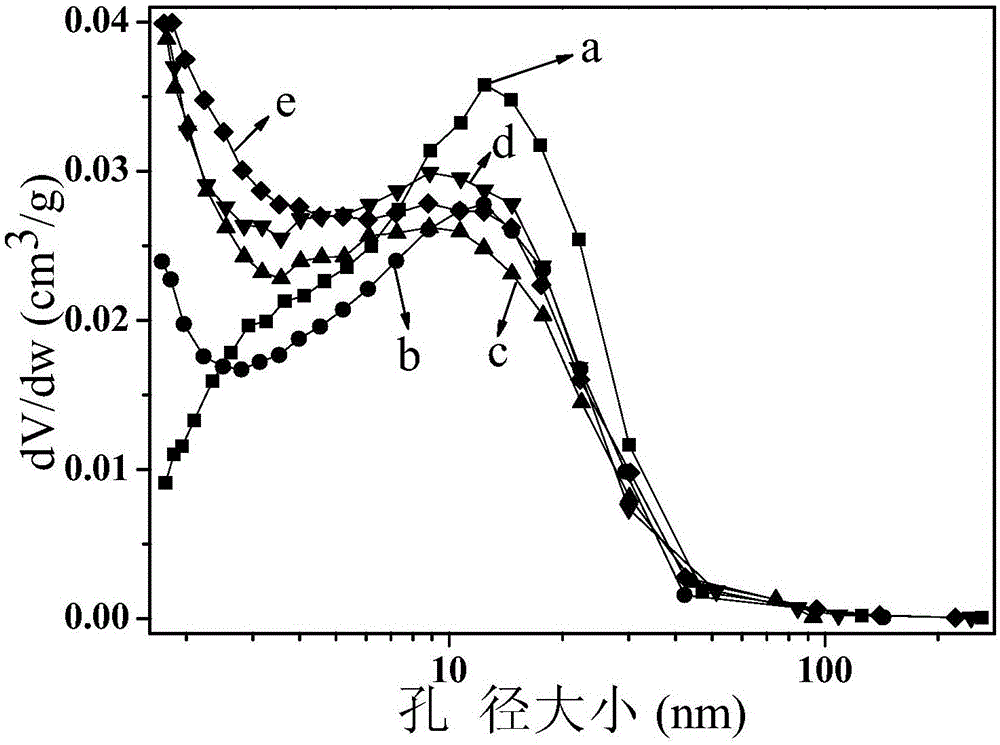

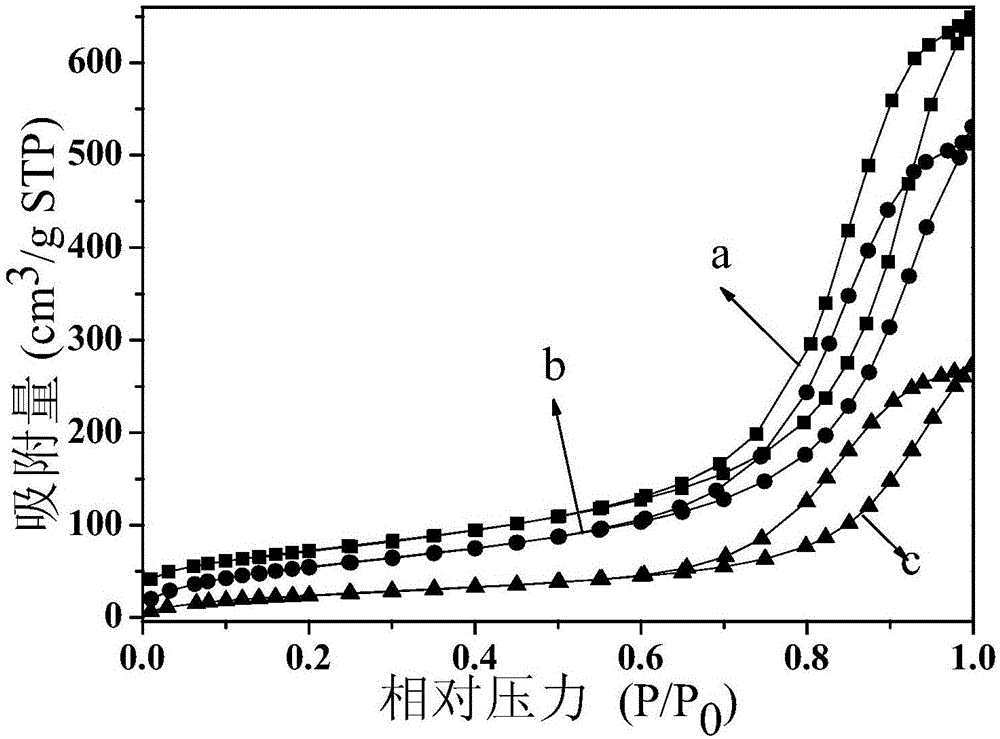

[0035] First, stir well at room temperature, dissolve 3g of F127 in 40ml of ethanol, and add 40ml of dilute nitric acid made of 0.68ml, 65wt% concentrated nitric acid to 3g of Shandong Senchi pseudoboehmite, degumming for 1h, at room temperature Stir them down to mix well. Then, the above solution was put into an oven at 60°C, evaporated at constant temperature for 24 hours, then dried in vacuum at 80°C, and finally roasted at 500°C for 4 hours to obtain the product, which was analyzed by X-ray powder diffraction (X-ray diffraction, XRD) as γ- Al 2 o 3 Phase, N 2 The specific surface area of adsorption-desorption test is 262.6m 2 / g, the pore volume is 0.96cm 3 / g, the average pore diameter is 14.6nm.

[0036] Application: Prepare 100ml, 50mg / L Cr(VI) solution with potassium dichromate, and adjust its pH to 3.0 with hydrochloric acid solution, then add 0.1g of the above-mentioned adsorbent under medium-intensity stirring, and after reaching adsorption equilibrium for a ...

Embodiment 2

[0038] First, fully stir at room temperature, dissolve 3gF127 in 40ml ethanol, and add 40ml dilute nitric acid made of 0.68ml, 65wt% concentrated nitric acid to 3g Shandong Senchi pseudoboehmite, degumming for 1h, in Stir them at room temperature to mix well. Then, the above solution was put into an oven at 60°C, evaporated at a constant temperature for 24 hours, then dried in vacuum at 80°C, and finally roasted at 500°C for 4 hours to obtain the product, which was γ-Al by XRD analysis. 2 o 3 Phase, N 2 Adsorption-desorption test has a specific surface area of 191.2m 2 / g, the pore volume is 0.77cm 3 / g, the average pore diameter is 14.4nm. Further dissolve 0.1111g PEI in 1.8ml ethanol under room temperature shaking to form PEI ethanol solution, add 1g mesoporous γ-Al 2 o 3 The powder was impregnated in equal volume at room temperature, and after standing for 24 hours, it was dried in vacuum at 80°C for 24 hours to prepare a composite adsorbent 10%PEI / γ-Al with a loadi...

Embodiment 3

[0041] First, fully stir at room temperature, dissolve 3gF127 in 40ml ethanol, and add 40ml dilute nitric acid made of 0.68ml, 65wt% concentrated nitric acid to 3g Shandong Senchi pseudoboehmite, degumming for 1h, and then Stir them at room temperature to mix well. Then, the above solution was put into an oven at 60°C, evaporated at a constant temperature for 24 hours, then dried in vacuum at 80°C, and finally roasted at 500°C for 4 hours to obtain the product, which was γ-Al by XRD analysis. 2 o 3 Phase, N 2 Adsorption-desorption test has a specific surface area of 247.2m 2 / g, the pore volume is 0.71cm 3 / g, and the average pore diameter is 11.4nm. Further dissolve 0.1111g TEOA in 1.8ml ethanol under shaking at room temperature to form an ethanol solution of TEOA, then add 1g mesoporous γ-Al 2 o 3 The powder was impregnated in equal volume at room temperature, and after standing for 24 hours, it was vacuum-dried at 80°C for 24 hours to prepare a composite adsorbent 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com