SiO2/gamma-AlOOH compound thin film for toxic Cr(VI) adsorption and preparing method and application thereof

A composite film, toxic technology, applied in the fields of adsorption water/sewage treatment, water/sludge/sewage treatment, silicon compounds, etc., can solve the problems of harsh conditions, high equipment requirements, low adsorption capacity, etc., and achieve good toughness and strength. , The effect of low equipment requirements and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

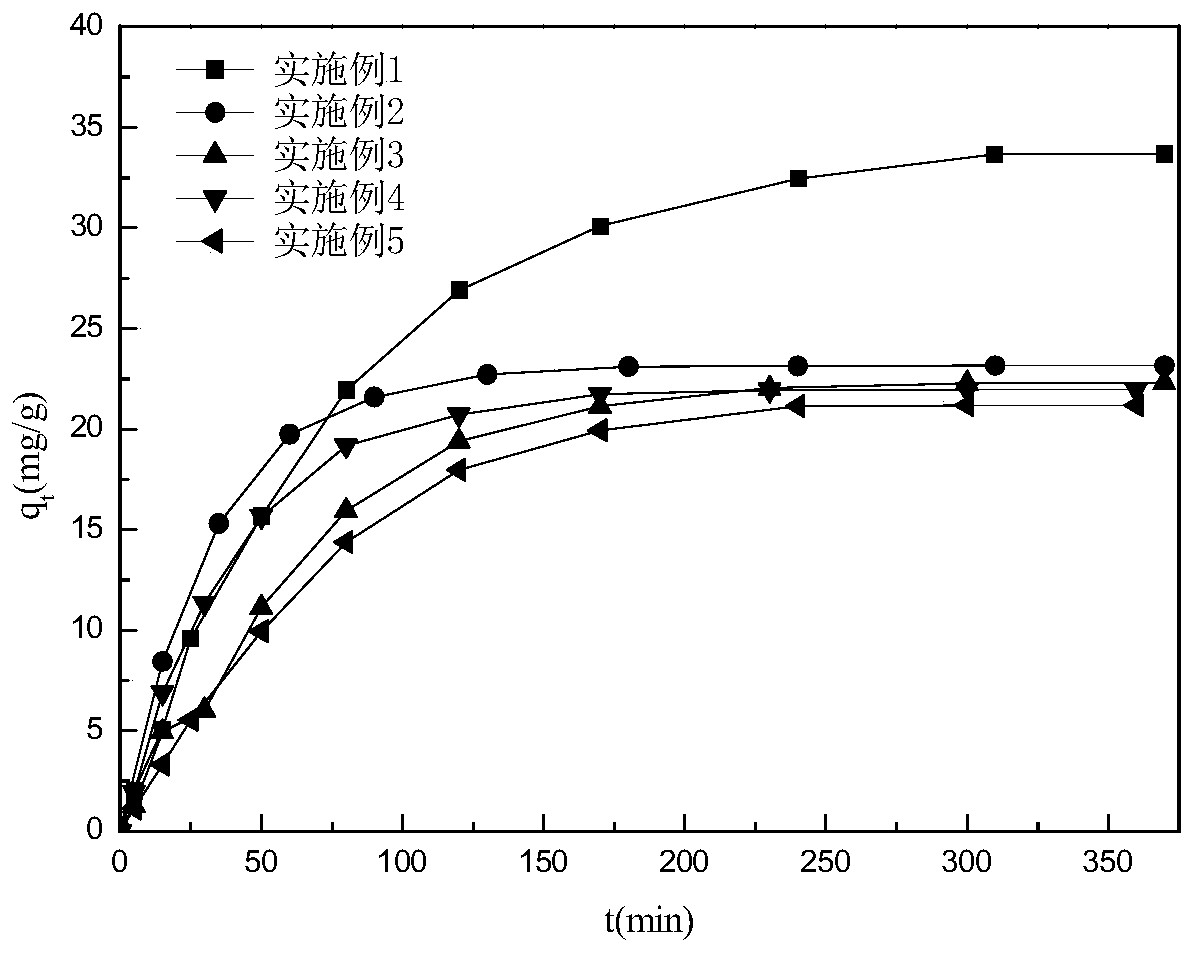

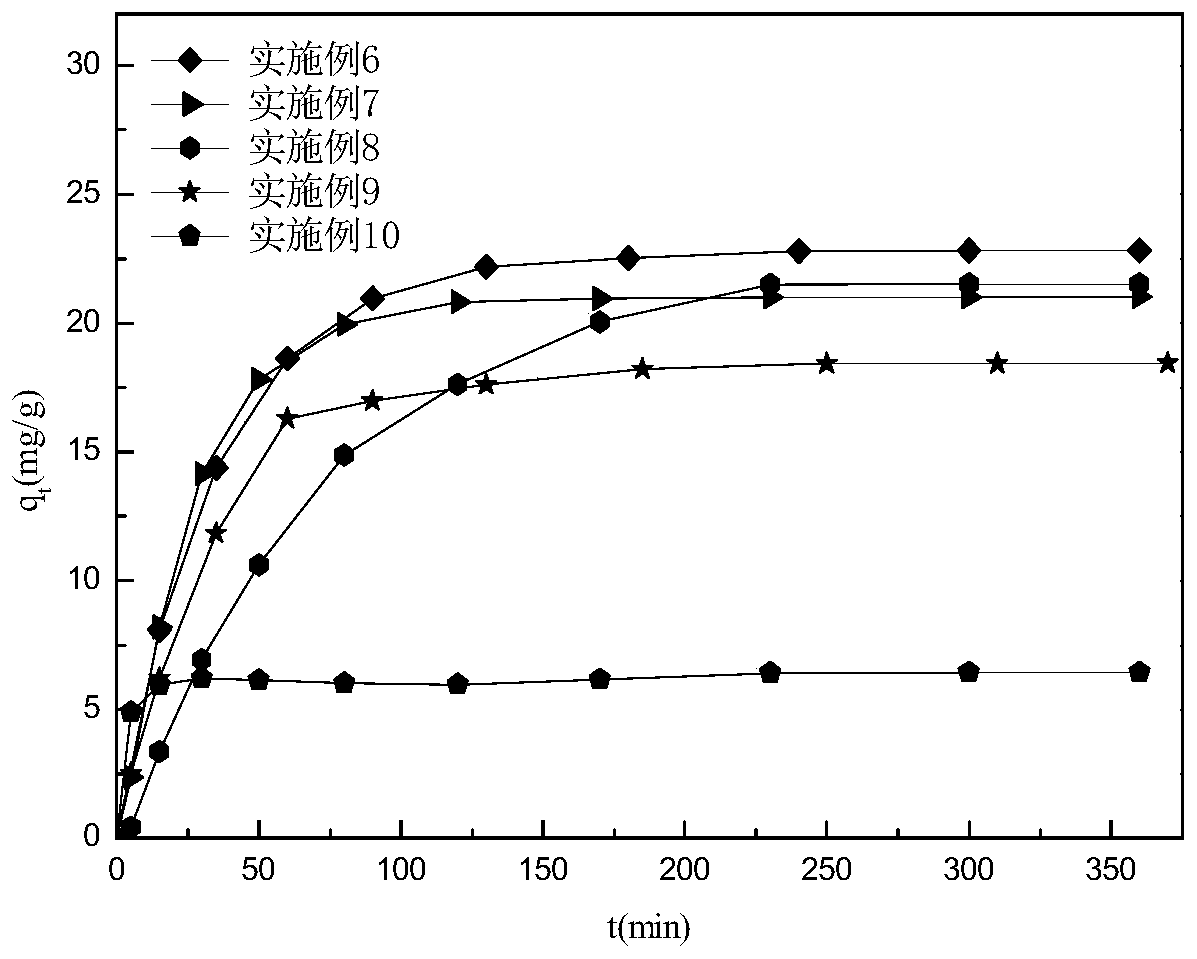

Embodiment 1

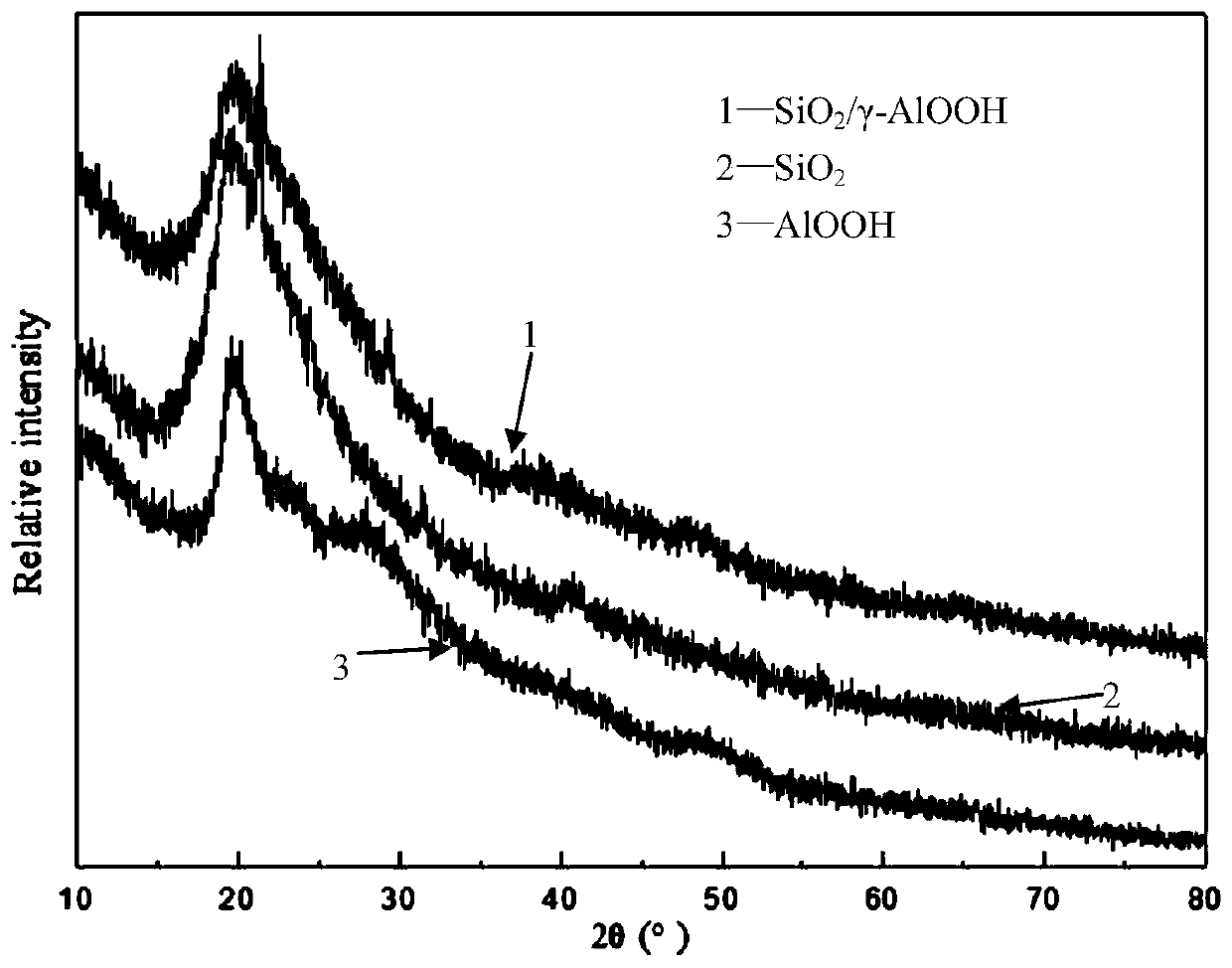

[0048] (1) Dissolve 2.2g CTAB in a mixed solution of 21.6g deionized water and 13.8g absolute ethanol at room temperature at a stirring rate of 500r / min; Add 5 g of tetraethyl orthosilicate dropwise, react at room temperature for 1 h at a stirring rate of 500 r / min, add 50 μL, 12 mol / L concentrated hydrochloric acid for further hydrolysis polymerization for 2 h, and obtain clear, transparent and stable SiO 2 Sol.

[0049] (2) Add 25mL of 5wt% ammonia water dropwise to 25mL, 0.96mol / L aluminum nitrate nonahydrate solution to obtain aluminum hydroxide precipitate, wash with deionized water several times to neutrality, and filter under reduced pressure to obtain aluminum hydroxide filter cake; ultrasonically disperse it in 50mL deionized water in an ultrasonic cleaning machine for 15-20min; press n(H + ) / n(Al 3+ )=0.3mol / mol adding HNO 3 , heated to 90 ° C for 2 h to obtain a stable γ-AlOOH sol.

[0050] (3) Take 5mL of SiO 2 The sol, 5mL of γ-AlOOH sol and 5mL of PVA aqueou...

Embodiment 2

[0053] (1) Dissolve 2.2g CTAB in a mixed solution of 21.6g deionized water and 13.8g absolute ethanol at room temperature at a stirring rate of 500r / min; Add 5 g of tetraethyl orthosilicate, react at room temperature for 1 h at a stirring rate of 500 r / min, add dropwise 50 μL, 12 mol / L concentrated hydrochloric acid for further hydrolysis and polymerization for 2 h, and obtain clear, transparent and stable SiO 2 Sol.

[0054] (2) Add 25mL, 5wt% ammonia water dropwise to 25mL, 0.96mol / L aluminum nitrate nonahydrate solution, obtain aluminum hydroxide precipitate, centrifuge and wash with deionized water several times until neutral, filter under reduced pressure to obtain aluminum hydroxide filter cake ; Ultrasonic in an ultrasonic cleaning machine for 15-20min to make it evenly dispersed in 50mL deionized water; press n(H + ) / n(Al 3+ )=0.3mol / mol adding HNO 3 , the temperature was raised to 90° C. for 2 h, and a stable γ-AlOOH sol was obtained.

[0055] (3) Take 5mL SiO 2 ...

Embodiment 3

[0060] (1) Dissolve 2.2g of CTAB in a mixed solution of 21.6g of deionized water and 13.8g of absolute ethanol at room temperature at a stirring rate of 500r / min; Add 5 g of tetraethyl orthosilicate dropwise, react at room temperature for 1 h at a stirring rate of 500 r / min, add 50 μL of 12 mol / L concentrated hydrochloric acid for further hydrolysis and polymerization for 2 h, and obtain clear, transparent and stable SiO 2 Sol.

[0061] (2) Add 25mL, 5wt% ammonia water dropwise to 25mL, 0.96mol / L aluminum nitrate nonahydrate solution to obtain aluminum hydroxide precipitate, wash with deionized water several times to neutrality, and filter under reduced pressure to obtain aluminum hydroxide filter cake; ultrasonically disperse it in 50mL deionized water in an ultrasonic cleaning machine for 15-20min; press n(H + ) / n(Al 3+ )=0.3mol / mol adding HNO 3 , the temperature was raised to 90° C. for 2 h, and a stable γ-AlOOH sol was obtained.

[0062] (3) Take 5mL of SiO 2 The sol,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com