High-thermal-conductivity rubber composite modified asphalt and preparation method thereof

A composite modified asphalt, high thermal conductivity technology, applied in building components, building insulation materials, buildings, etc., can solve problems such as poor thermal conductivity and inability to meet application requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A high thermal conductivity rubber compound modified asphalt, in parts by weight, comprises the following raw materials: 2.5 parts of thermally conductive fillers, 13 parts of rubber, 1.5 parts of PE plastics, 83.15 parts of asphalt and 0.15 parts of stabilizers. Among them, carbon fiber T800 is specifically selected as the thermally conductive filler, and the mesh number of the carbon fiber is controlled to be 50-1000 mesh (100 mesh is used in this embodiment). Rubber comes from waste truck tires. In addition to truck tires, sole rubber, waste bicycle tires and car tires can also be used. The material of the rubber can be natural rubber, styrene-butadiene rubber, butadiene rubber, butyl rubber, etc. The main component of the rubber in the truck tire in this embodiment is natural rubber. The truck tires are pulverized into particles with a particle size of 30-40 meshes (30 meshes are used in this embodiment), and then the rubber particles are subjected to conventional d...

Embodiment 2

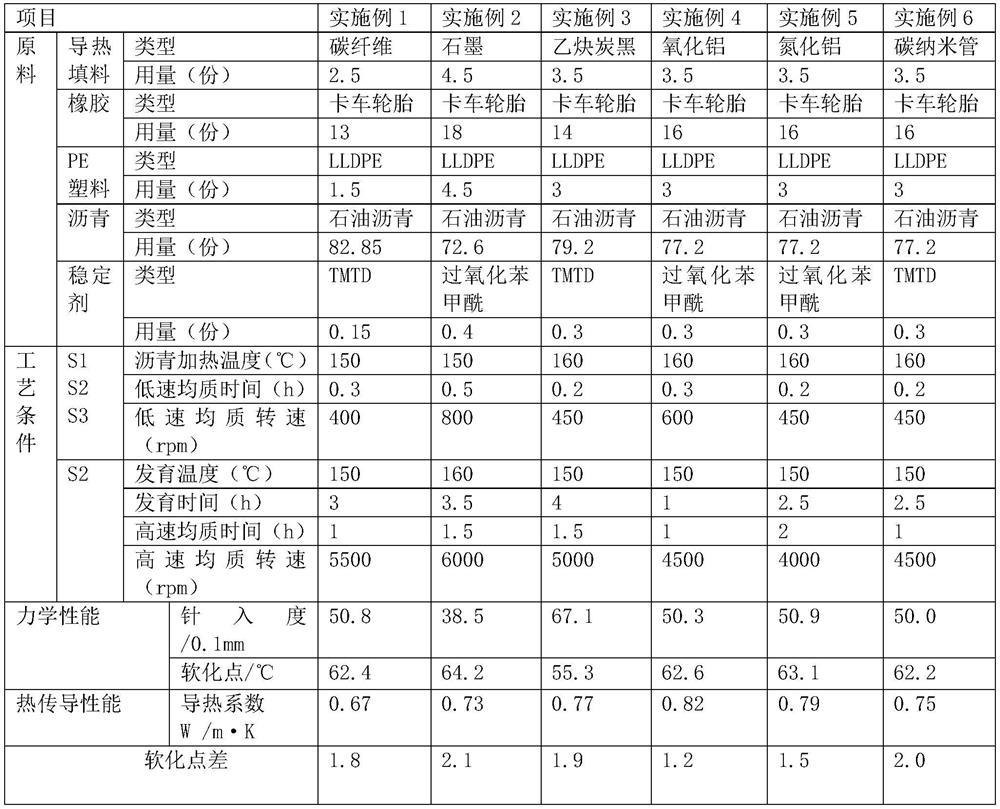

[0031] Example 2-Example 6 are basically the same as Example 1, the difference lies in the selection of the consumption of some raw material types, and the selection of process conditions, see Table 1 for details. In Example 2, the graphite is 300 mesh microcrystalline graphite powder, and the carbon content is 60%; in Example 3, the apparent specific volume (cm 3 / g) is 14-17, resistivity (Ω·m)≤2.5; in Example 5, the carbon nanotubes are walled carbon nanotubes, the purity is >95%, the length is 3-12 μm, the inner diameter is 3-5 nm, and the outer diameter is 3-5 nm. 8-15nm density 0.15g / cm 3 . In Examples 1-6, the particle size of the thermally conductive filler was maintained between 500-2000 nm.

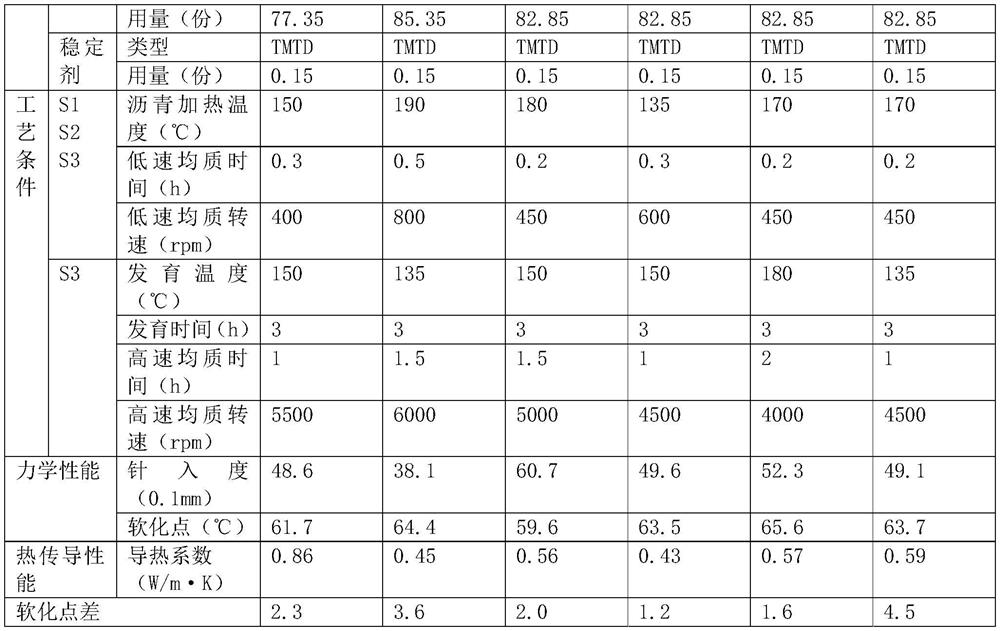

[0032]Comparative Example 1-Example 6 are basically the same as Example 1, the difference lies in the selection of the consumption of some raw material types, and the selection of process conditions, see Table 2 for details. The performance test was carried out on the composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com