Lactobacillus pentosus and application thereof in freeze-thaw resistant silage

A Lactobacillus pentosus and silage technology, applied in the field of microorganisms, can solve the problems of difficulty in storage, environmental temperature difference of species and quantity affecting oat silage, aerobic spoilage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 The separation and screening process of Lactobacillus pentosus 260

[0034] Collected in Haibei, Haidong, Hainan and Xining areas of Qinghai Province from January to the end of April 2021, a total of 57 silage samples and 1 herdsman-made yogurt sample were collected from 19 sampling sites (the information of sample collection sites is shown in Table 1. Show). After sampling, 20 g of the silage samples were respectively weighed into 180 mL of sterile distilled water, shaken at 4 °C for 1 h, and then serially diluted in sterile distilled water for 10 hours. -1 to 10 -5 , respectively take the stock solution, 10 -3 , 10 -5 The sample dilution solution was spread on solid MRS medium (Land Bridge Technology Co., Ltd., Beijing, China) for 48 h. The lactic acid bacteria with fast growth rate were selected and inoculated into the liquid MRS medium for 48 hours at 37°C, followed by continuous streaking and purification to separate the lactic acid bacteria.

[0035...

Embodiment 2

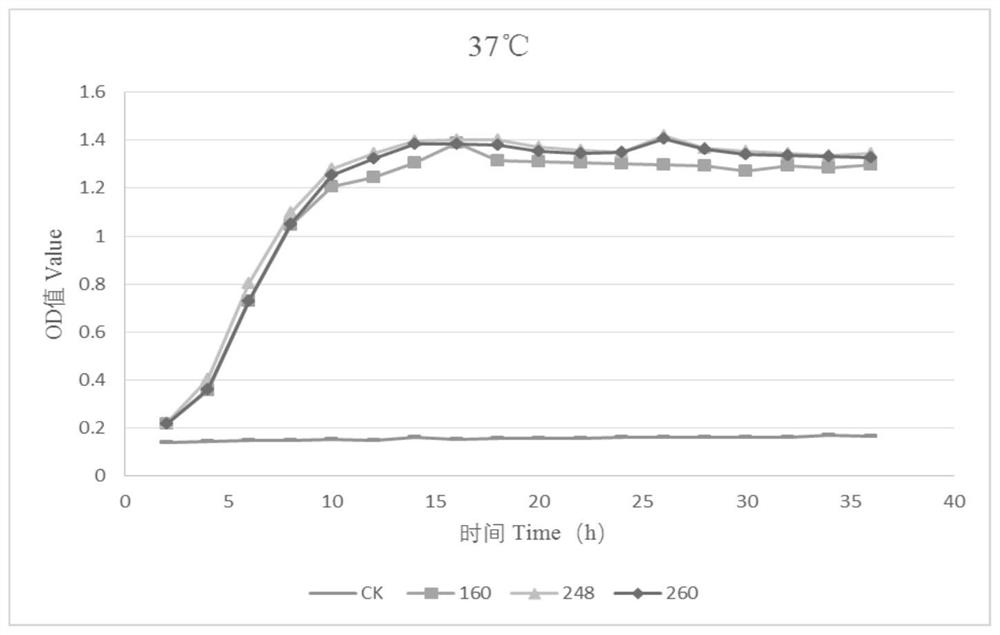

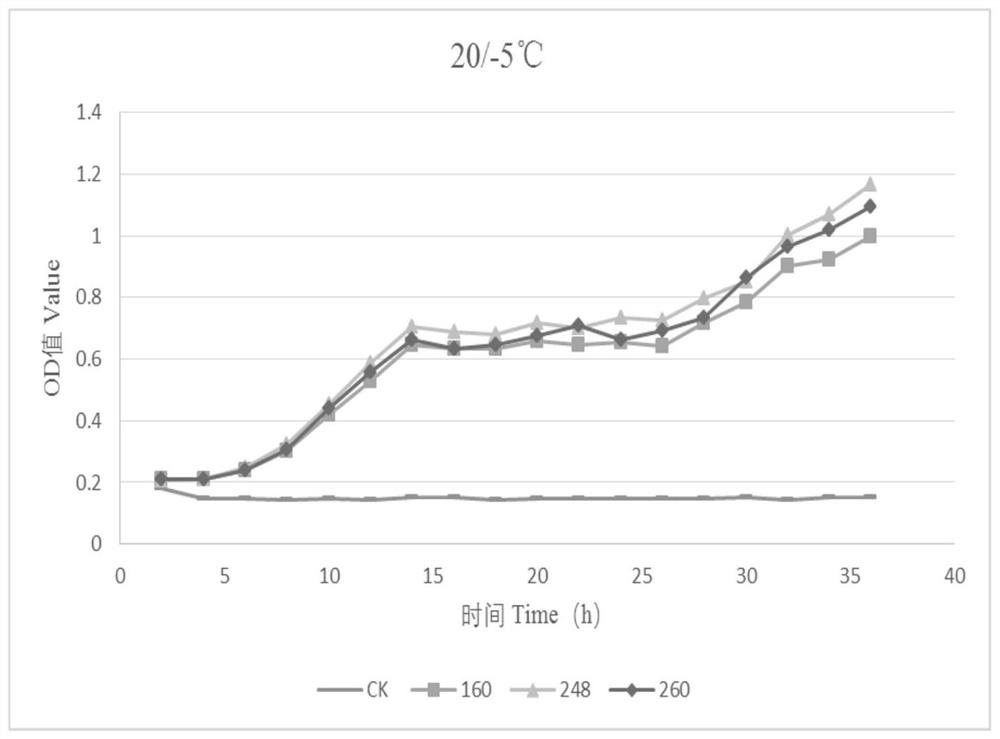

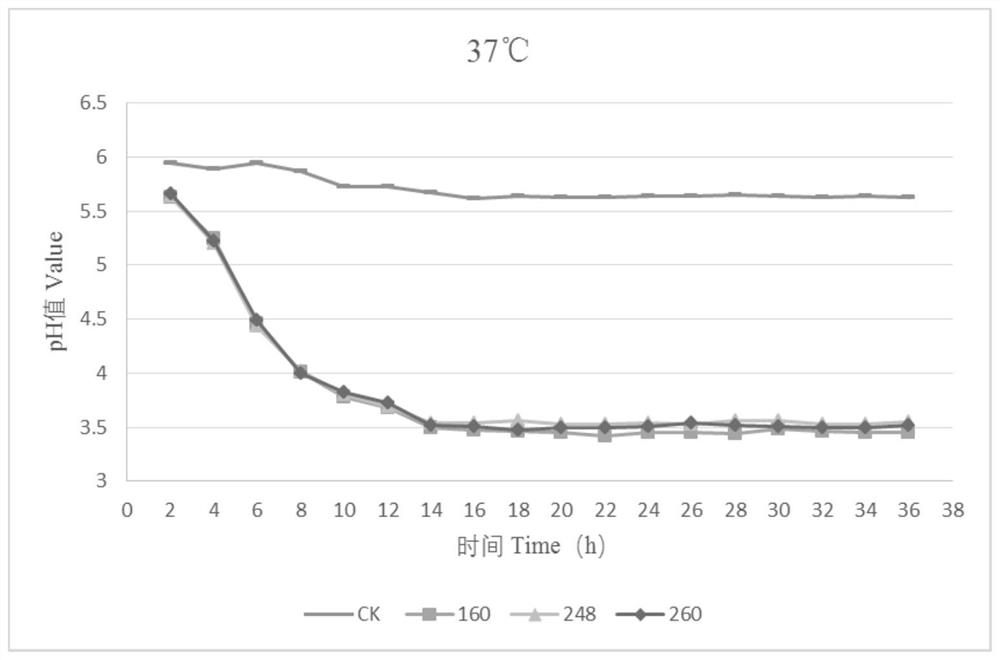

[0071] Example 2 Preparation of silage

[0072] The oats for test were harvested 10cm off the ground at the milk maturity stage. After the shredding machine was cut short and kneaded, the oats were thoroughly mixed after a short drying period. One high-quality freeze-thaw-resistant pentose lactic acid bacteria 260 and commercial bacteria (purchased from Taiwan) were selected. Lactobacillus plantarum from Yaxin Biotechnology Co., Ltd.) was used as an inoculant to dissolve and dilute the strain culture to 10 6 About cfu / mL, every 100g of chopped raw materials (1-2cm) is evenly sprayed with 3mL of bacterial liquid, mixed thoroughly, and the sprayed amount of sterilized distilled water is compared. Put 700 g of the treated oats into polyethylene plastic bags, compact them, and then vacuumize them. Each group of oats was treated for 3 repetitions, and placed in incubators at 20 °C and 20 / -5 °C (alternating, 12 h each), and silaged for 60 hours. The bags were opened, and all sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com