Engineering bacterium of fermenting production of optical pure L-lactate by utilizing xylose and construction thereof

An engineering bacteria and optical technology, applied in the fields of microbial fermentation and genetic engineering, to reduce production costs, simplify post-extraction processes, and promote mass accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

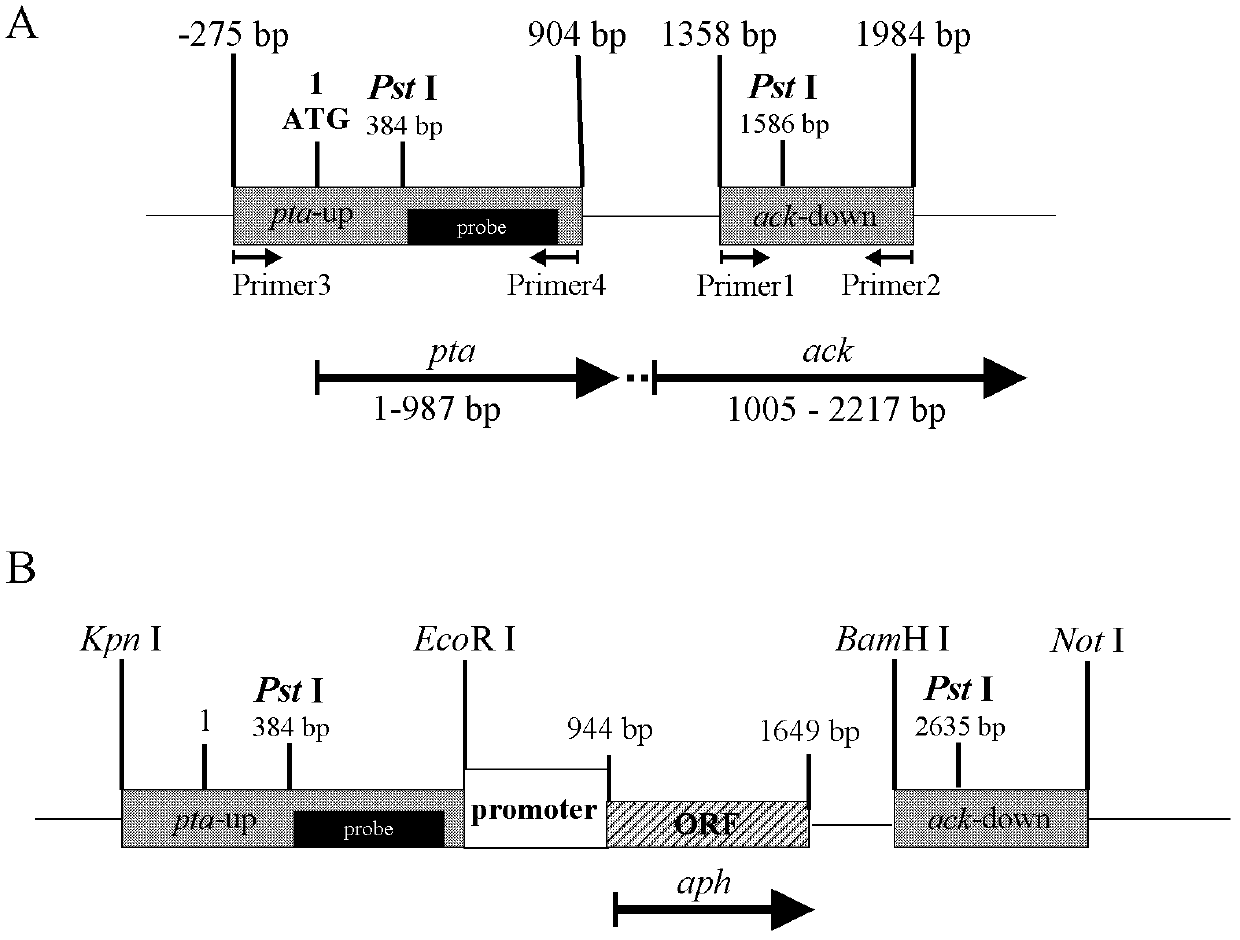

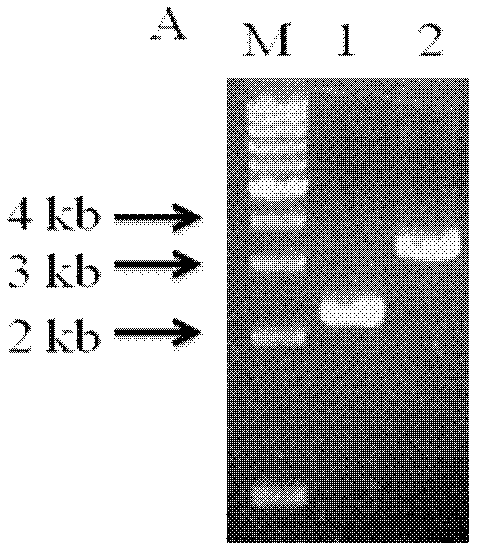

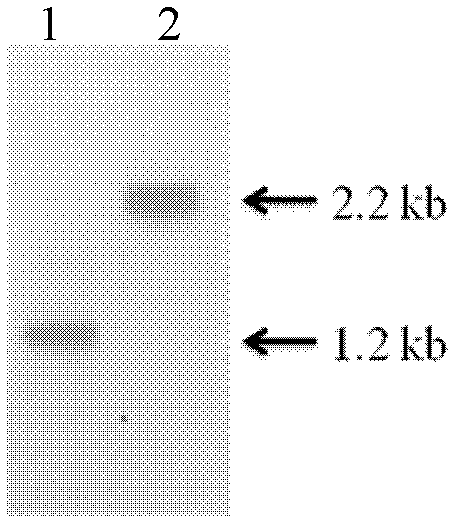

[0031] Construction of an engineering bacterium that can produce optically pure L-lactic acid by fermenting xylose

[0032] An engineering bacterium that can produce optically pure L-lactic acid by xylose fermentation is constructed by inserting a heat-resistant kana resistance coding gene between the genes encoding acetate kinase and phosphotransacetylase to realize acetate kinase and phosphotransferase. Knockout of the gene encoding acetylase can block the branch of acetic acid metabolism, and can preliminarily identify positive recombinants through kana resistance screening. The principle of the specific blocking process is as follows: figure 1 As shown, the specific operation includes the following steps:

[0033] (1) Construction of the Escherichia coli and thermoanaerobic bacillus shuttle vector pBlue-aph carrying the Kana resistance expression cassette: Carry out the whole gene synthesis of the aph gene according to the Kana resistance gene (GenBank: V01547), and inser...

Embodiment 2

[0053] Comparison of engineered bacteria that can ferment xylose to produce optically pure L-lactic acid and wild-type lactic acid

[0054] (1) Seed cultivation

[0055] Insert the engineering bacteria of Example 1 into a 20ml serum bottle containing 10ml of seed culture medium, and cultivate at 55°C and 150r / min for 12h, so that the OD value reaches above 0.8. Inoculate into a 125ml serum bottle containing 50ml seed medium at a ratio of 1:5, culture at 55°C and 150r / min for 12h, and make the OD value reach above 1.0.

[0056] (2) shake flask culture

[0057] The seed solution cultivated in step (1) is connected to a 125ml serum bottle equipped with 50ml fermentation medium according to 10% inoculum amount, and nitrogen gas is filled to a pressure of 0.04MPa. The culture was continued for 24 hours with 10g / L xylose as the substrate.

[0058] The operation of the wild-type strain was the same as above.

[0059] The metabolites were detected by HPLC, and the comparison resul...

Embodiment 3

[0084] Whether the culture medium is sterilized affects the engineering bacterium fermentation product of the present invention

[0085] According to 10% inoculum amount, the seed liquid of embodiment engineering bacteria is inserted in the 5L automatic reaction kettle of NBS company that 3L fermentation medium is housed. Before inoculation, the reaction kettle was first fed with nitrogen for 30 minutes, and then nitrogen was fed for 30 minutes after inoculation to ensure that the fermentation environment was oxygen-free. During the fermentation process, 5mol / L NaOH was used to control the pH value to 6.8.

[0086] Lactic acid, acetic acid, ethanol and sugar concentrations in the fermentation products were determined (Table 2).

[0087] Using 50g / L glucose as substrate for continuous fermentation for 72 hours, the concentration of lactic acid can reach 47.2g / L, the conversion rate can reach 0.95g / g, and the optical purity of L-lactic acid can exceed 99.5%.

[0088] Using 50g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com