Coating aluminum alloy template and coating process thereof

An aluminum alloy template and process technology, which is applied in metal material coating process, mold shell/template components, fusion spray plating, etc., can solve the problems of slow turnover efficiency of aluminum alloy templates, scratches on the coating layer, and easy erosion. , to reduce the risk of scratches, protect the film layer, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

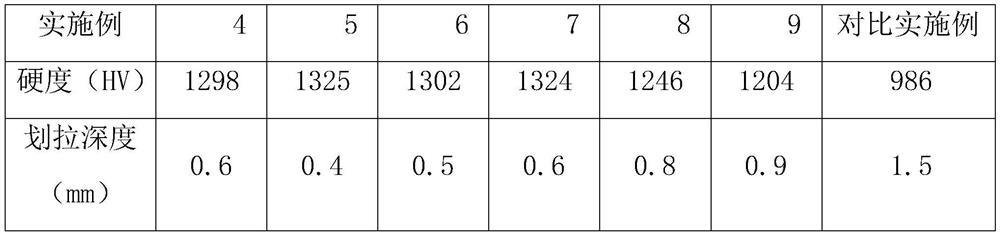

Examples

Embodiment 1

[0028] The present embodiment of the preparation of titanium / nickel-clad aluminum powder, the steps are as follows: the titanium dioxide powder and silane coupling agent, iron trioxide powder mixed, at a frequency of 1500r / min vibration grinding 1h, and then add nickel-clad aluminum powder, stirred evenly after calcination at a high temperature of 800 ° C for 10min, taken out, cooled to 200 ° C, followed by ultrasonic oscillation for 20min, frequency of 20kHz, to obtain titanium / nickel-clad aluminum powder; The mass of nickel-clad aluminum powder and ferric trioxide powder is 1.5kg, 1kg, 0.1kg, respectively, the particle size of the titanium dioxide powder is 15μm, and the particle size of nickel-clad aluminum powder is 25μm.

Embodiment 2

[0030] The present embodiment of the preparation of titanium - nickel-clad aluminum powder, the steps are as follows: the titanium dioxide powder and silane coupling agent, iron trioxide powder mixed, at a frequency of 1750r / min vibration grinding 1.5h, followed by the addition of nickel-clad aluminum powder, stirred evenly at 900 ° C high temperature calcination for 15min, taken out, cooled to 250 ° C, followed by ultrasonic oscillation 25min, frequency of 23kHz, to obtain titanium - nickel-clad aluminum powder; The mass of nickel-clad aluminum powder and ferric trioxide powder is 2.25kg, 1.25kg, 0.3kg, respectively, the particle size of the titanium dioxide powder is 20μm, and the particle size of nickel-clad aluminum powder is 32μm.

Embodiment 3

[0032]The present embodiment of the preparation of titanium / nickel-clad aluminum powder, the steps are as follows: the titanium dioxide powder and silane coupling agent, iron trioxide powder mixed, at a frequency of 2000r / min vibration grinding 2h, and then add nickel-clad aluminum powder, stirred evenly after calcination at a high temperature of 1000 ° C for 20min, take out, cooled to 300 ° C, followed by ultrasonic oscillation for 30min, frequency of 25kHz, to obtain titanium / nickel-clad aluminum powder; The mass of nickel-clad aluminum powder and ferric trioxide powder is 3kg, 1.5kg, 0.5kg, respectively, the particle size of the titanium dioxide powder is 25μm, and the particle size of nickel-clad aluminum powder is 40μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com