Magnetic ceramic pigment used as printing supplies and preparation method thereof

A technology for magnetic ceramics and printing consumables, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve the problems of loss of color, high preparation cost, poor conductivity, etc. The effect of migration controllability and strong wave absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

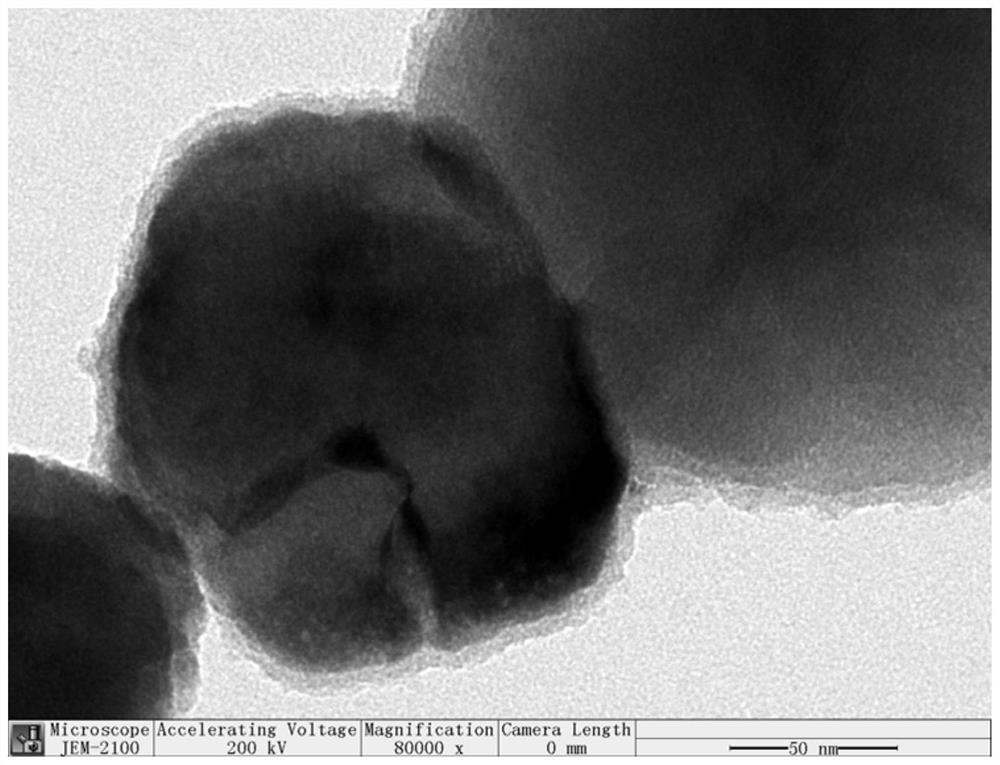

Image

Examples

Embodiment 1

[0029] The present embodiment is used as the preparation method of the magnetic ceramic color material of printing consumables, and its steps are as follows:

[0030] (1) Preparation of encapsulated core powder

[0031] Weigh 5g Fe with an average particle size of 0.5μm 3 O 4 Soft magnetic material particles, add 0.5g 10wt% PEG solution and 25g water, put it into a 500mL beaker, stir vigorously for 1h to form a stable suspension; then add 25g 27.48wt% ammonium zirconium carbonate solution, continue stirring for 1h, use household Microwave oven, heat in medium fire mode for 18 times, each time for 10s, then put the microwave-treated suspension into a 60°C oven to dry to obtain powder; move the powder into an alumina crucible, heat it at 900°C, N 2 The calcination was carried out under the protection of the atmosphere, and the temperature was kept for 2 hours. After cooling to room temperature, Fe coated with a dense zirconia layer was obtained after grinding. 3 O 4 powder (...

Embodiment 2

[0040] The present embodiment, as the preparation method of the magnetic ceramic colorant of printing consumables, differs from the first embodiment in that:

[0041] The preparation of step (1) encapsulated inner core powder is:

[0042] Add 80 mL of ethanol, 16 mL of deionized water and 1 g of Fe with an average particle size of 0.5 μm after sonication in a 1000 mL beaker 3 O 4 Soft magnetic material particles, stir with a polytetrafluoroethylene stirring rod, add 1 mL of 1 wt% triblock polymer P123, stir for 0.5 h, add 3 mL of 25 wt % ammonia water, and stir for 0.5 h, add 1 mL of ethyl orthosilicate ester TEOS; after the reaction for 1 h, the obtained precipitate was washed three times with deionized water and ethanol each, and the powder after drying was dried at 1100 ° C under N 2 The calcination was carried out under the protection of the atmosphere, and the temperature was kept for 20 minutes. After cooling to room temperature, Fe coated with a dense silica layer was...

Embodiment 3

[0044] The present embodiment, as the preparation method of the magnetic ceramic colorant of printing consumables, differs from the first embodiment in that:

[0045] The preparation of step (1) encapsulated inner core powder is:

[0046] Weigh 5g Fe with an average particle size of 0.5μm 3 O 4 Soft magnetic material particles, add 0.5g 10wt% PEG solution and 25g water, put it into a 500mL beaker, stir vigorously for 1h to form a stable suspension; then add 25g 27.48wt% ammonium zirconium carbonate solution, continue stirring for 1h, use In a household microwave oven, heat 18 times in medium heat mode, each time for 10s; use a magnet to adsorb the powder on the bottom of the beaker, remove excess solution, and wash it with distilled water 3 times; finally add 20mL of distilled water, and ultrasonically form suspension A;

[0047] Prepare solution A: 9mL 28% concentrated ammonia water + 16.25mL ethanol + 24.75mL water, place in a 150mL beaker and stir magnetically; prepare so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com