Preparation method of nano composite material and lithium ion electrode negative electrode material thereof

A nanocomposite material and nanomaterial technology, applied in the field of nanocomposite materials, can solve problems such as poor electrochemical performance, achieve low toxicity, relieve volume expansion, and shorten the electron and ion transmission path.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

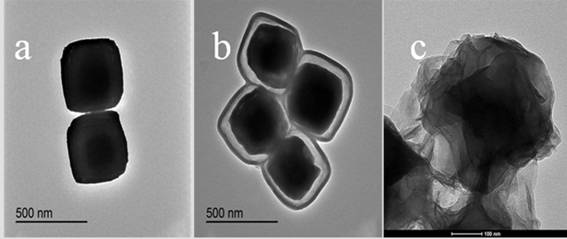

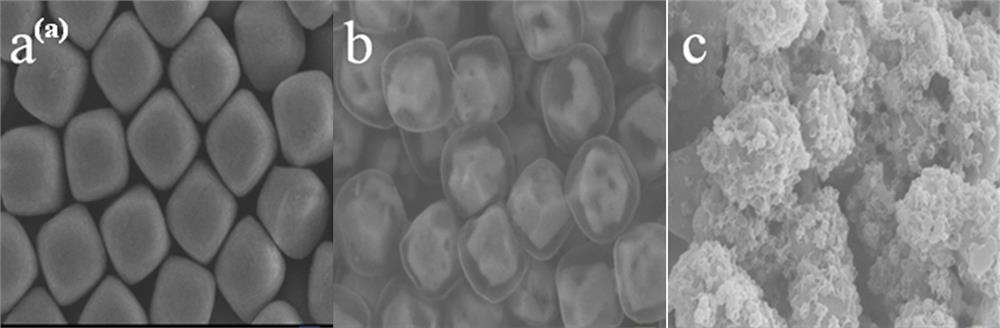

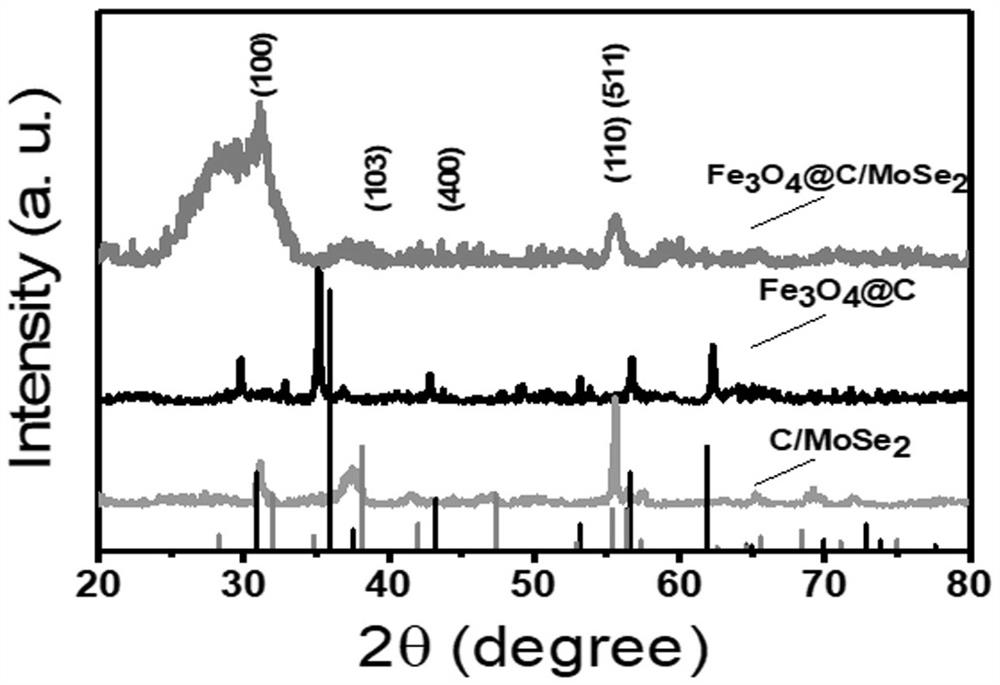

[0025] The first step is to prepare core-shell Fe 3 O 4 @C : 80mg made in the laboratory α -Fe 2 O 3 Nano-cubes, water and ammonia water are uniformly dispersed in ethanol under ultrasound, wherein the volume ratio of water, ammonia water and anhydrous ethanol is 2.5:1:20, α -Fe 2 O 3 The dispersion concentration was 50 mg / 100 mL, the mixed solution was placed in a 250 mL three-necked flask, mechanically stirred at a water bath temperature of 30 °C, and then 30 mg of resorcinol and 64 μL of formaldehyde solution were added, and stirred for 24 h. , the precipitate was collected by centrifugation, and dried in a vacuum drying oven at 60 °C for 12 h. Then annealed at 700 °C for 3 h under the protection of argon in a tube furnace, the annealed sample was etched with 40 mL of hydrochloric acid (4 mol / L) for 30 min, then washed with water, centrifuged to separate the etched solid phase, and finally moved to vacuum Dry in a drying oven at 60 °C for 12 h to obtain a carbon box ...

Embodiment 2

[0028] (1) Preparation of core-shell Fe 3 O 4 @C: Preparation of core-shell Fe 3 O 4 @C : 80mg made in the laboratory α -Fe 2 O 3 Nano-cubes, water and ammonia water are uniformly dispersed in ethanol under ultrasound, wherein the volume ratio of water, ammonia water and anhydrous ethanol is 2:1:25, α -Fe 2 O 3 The dispersion concentration of the solution was 50 mg / 100 mL, the mixture was poured into a 250 mL three-necked flask, mechanically stirred at a water bath temperature of 25 °C, and then 25 mg of resorcinol and 54 μL of formaldehyde solution were added, and stirred for 30 h until the reaction was over. After that, the precipitate was collected by centrifugation, dried in a vacuum drying box at 60 °C for 12 h; then annealed at 750 °C for 5 h under the protection of argon in a tube furnace, and the annealed sample was etched with 40 mL of hydrochloric acid (4 mol / L) for 30 min. , washed twice with deionized water, and finally moved to a vacuum drying oven at 60 °...

Embodiment 3

[0031] (1) Preparation of core-shell Fe 3 O 4 @C: 80mg made in the lab α -Fe 2 O 3 Nano-cubes, water and ammonia water are uniformly dispersed in ethanol under ultrasound, wherein the volume ratio of water, ammonia water and absolute ethanol is 2:1:23, α -Fe 2 O 3 The dispersion concentration was 50 mg / 100 mL, the mixture was poured into a 250 mL three-necked flask, mechanically stirred at a water bath temperature of 35 °C, and then 75 mg of resorcinol and 160 μL of formaldehyde solution were added, and stirred for 24 h. , the water precipitate was collected by centrifugation, and dried in a vacuum drying oven at 60 °C for 12 h. Then annealed at 720 °C for 4 h under the protection of argon in a tube furnace, the annealed samples were etched with 40 mL of hydrochloric acid (4 mol / L) for 30 min, washed with deionized water for 3 times, and finally moved to a vacuum drying box to dry at 60 °C 12h, obtain the ferric tetroxide as the core carbon box as the shell (Fe 3 O 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com