Coating method of nickel cobalt lithium manganate positive electrode material

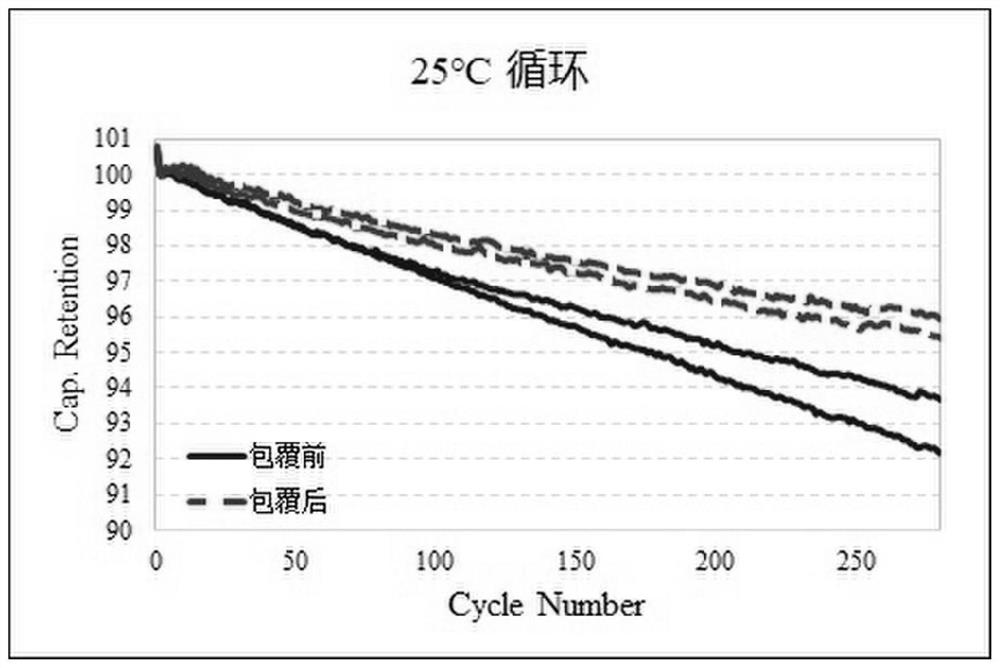

A technology of nickel-cobalt-lithium-manganese-manganese oxide and positive electrode materials, applied in battery electrodes, structural parts, electrical components, etc., can solve the problems of battery cycle attenuation, increased processing costs, damage, etc., to avoid irreversible loss of lithium and improve comprehensive performance , reduce the effect of premature chalking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a method for coating a cathode material of nickel cobalt lithium manganate.

[0036] (1) dissolving aluminum dihydrogen phosphate in deionized water to obtain a uniform aqueous solution containing Al element, preparing a concentration of 2 mol / L, and then cross-linking to obtain an Al-containing saline gel;

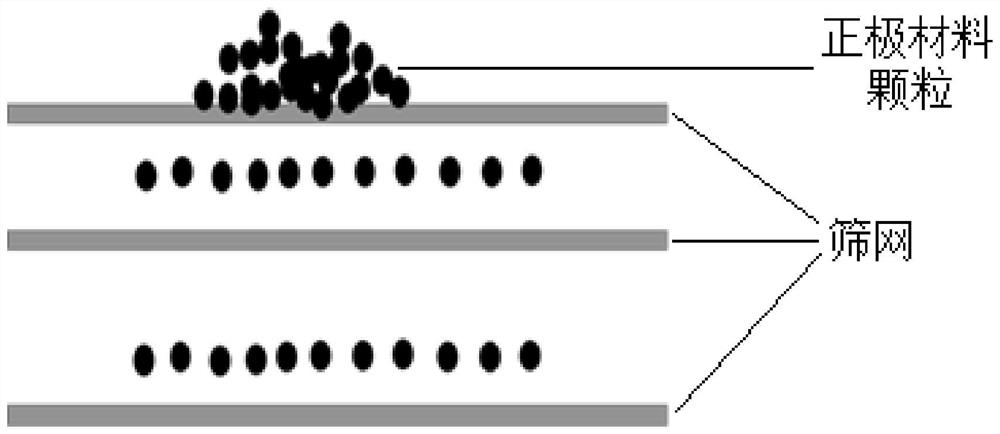

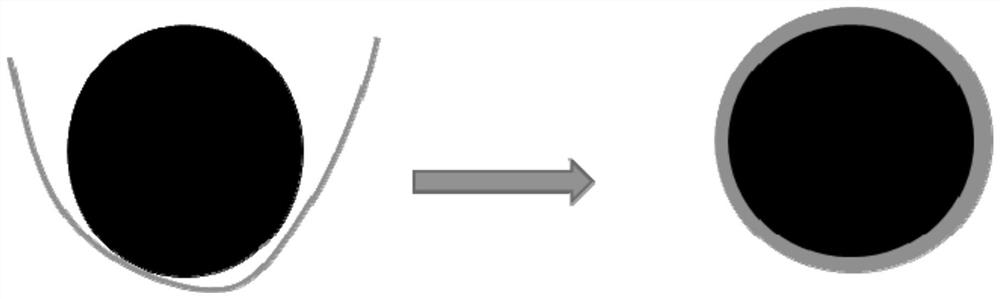

[0037] (2) Coating the Al-containing saline gel obtained in step (1) on the screen, forming a thin film with the screen holes of the screen, and coating the nickel-cobalt lithium manganate cathode material particles; nickel-cobalt lithium manganate; When the positive electrode material particles are in contact with the film, the film stretches and completely wraps the nickel-cobalt lithium manganate positive electrode material particles, and the nickel-cobalt lithium manganate positive electrode material particles fall off (such as figure 1 described); obtain the nickel-cobalt lithium manganate cathode material encapsulated by the initial A...

Embodiment 2

[0042] This embodiment provides a method for coating a cathode material of nickel cobalt lithium manganate.

[0043] (1) dissolving aluminum dihydrogen phosphate in deionized water to obtain a uniform aqueous solution containing Al element, preparing a concentration of 0.5 mol / L, and then cross-linking to obtain an Al-containing hydrogel;

[0044] (2) Coating the Al-containing saline gel obtained in step (1) on the screen, forming a thin film with the screen holes of the screen, and coating the nickel-cobalt lithium manganate cathode material particles; nickel-cobalt lithium manganate; During the falling process of the positive electrode material particles, the film contacts the film, the film stretches and completely wraps the nickel-cobalt lithium manganate positive electrode material particles, and the nickel-cobalt lithium manganate positive electrode material particles fall off; the nickel-cobalt lithium manganate positive electrode wrapped by the initial Al-containing bri...

Embodiment 3

[0048] This embodiment provides a method for coating a cathode material of nickel cobalt lithium manganate.

[0049](1) dissolving aluminum dihydrogen phosphate in deionized water to obtain a uniform aqueous solution containing Al element, preparing a concentration of 5 mol / L, and then cross-linking to obtain an Al-containing saline gel;

[0050] (2) Coating the Al-containing saline gel obtained in step (1) on the screen, forming a thin film with the screen holes of the screen, and coating the nickel-cobalt lithium manganate cathode material particles; nickel-cobalt lithium manganate; During the falling process of the positive electrode material particles, the film contacts the film, the film stretches and completely wraps the nickel-cobalt lithium manganate positive electrode material particles, and the nickel-cobalt lithium manganate positive electrode material particles fall off; the nickel-cobalt lithium manganate positive electrode wrapped by the initial Al-containing brin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com