Supergravity regeneration device and system for establishing temperature gradient

A temperature gradient and regeneration device technology, which is applied in separation methods, products, and dispersed particle separation, etc., can solve the problems of enhanced corrosion of equipment and high concentration of lean amine solution, and achieve improved purity, reduced corrosion, and increased contact time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

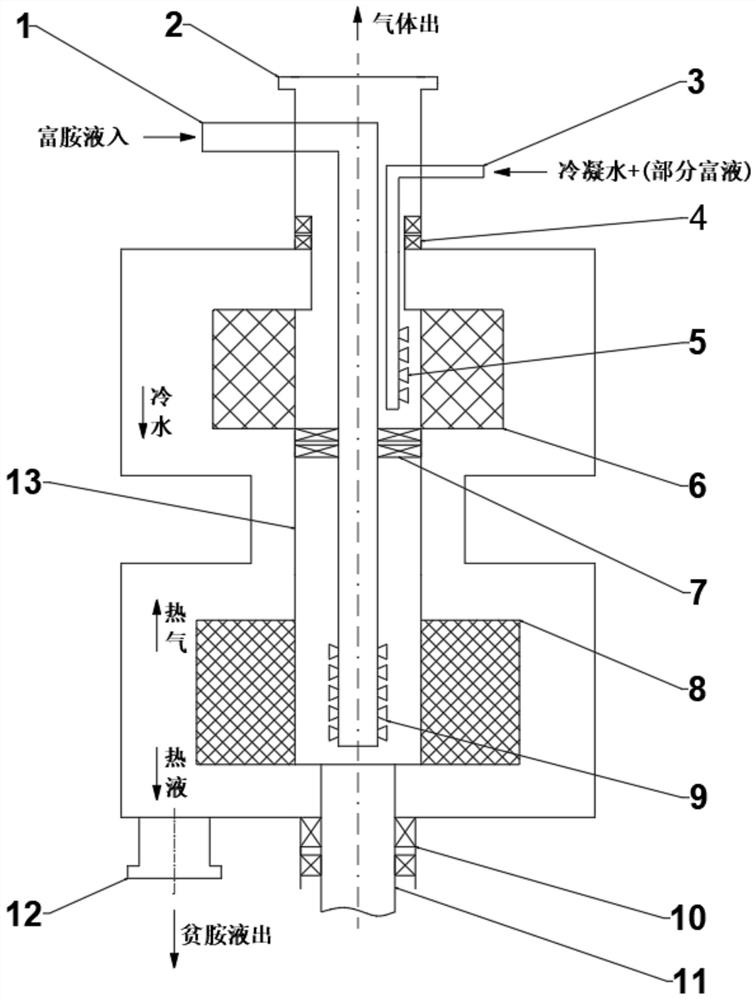

[0032] Embodiment one, such as figure 1 As shown in - 2, a high-gravity regeneration device for establishing a temperature gradient according to an embodiment of the present invention includes a casing, a gas outlet 2 is set at the center of the top of the casing, and a lean Amine liquid outlet 12, a hollow rotating shaft 13 is provided at the center of the housing axial direction, the top of the hollow rotating shaft 13 communicates with the gas outlet 2, and the bottom of the hollow rotating shaft 13 communicates with the solid rotating shaft 11 Fixedly connected, the other end of the solid rotating shaft 11 penetrates to the outside of the housing to connect with the motor, and the two sides of the outer surface of the housing near the end of the gas outlet 2 are respectively inserted with a rich amine liquid infusion tube 1, a condensation Water pipe 3, the ends of the rich amine liquid pipe 1 and the condensed water pipe 3 go deep into the hollow rotating shaft 13, and th...

Embodiment 2

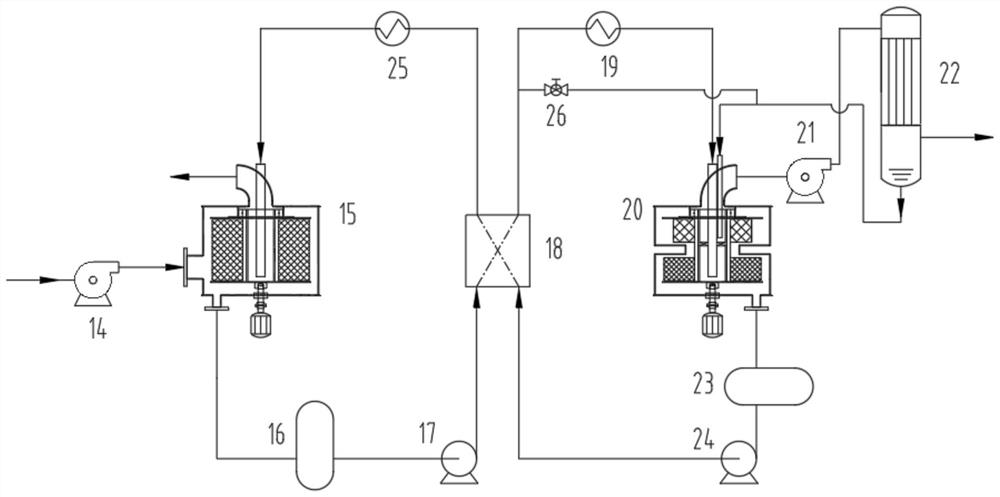

[0036] Embodiment two, such as figure 1 - As shown in 2, a high-gravity regeneration system for establishing a temperature gradient according to an embodiment of the present invention includes a high-gravity regeneration device 20, a first axial flow fan 14, a high-gravity absorption device 15, a rich liquid tank 16, and a rich liquid transport Pump 17, lean-rich liquid heat exchanger 18, rich-liquid heater 19, second axial flow fan 21, condenser 22, lean-liquid tank 23, lean-liquid delivery pump 24, ice machine 25, rich amine liquid regulating valve 26, The supergravity absorbing device 15 is respectively connected with the first axial flow fan 14, the ice machine 25, and the rich liquid tank 16, and the rich liquid tank 16 is connected with the rich liquid delivery pump 17, and the The rich liquid delivery pump 17 is connected to the lean-rich liquid heat exchanger 18, and the high-gravity regeneration device 20 is connected to the rich liquid heater 19, the second axial flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com