Preparation method of modified TiO2 carrier loaded V-Mo denitration catalyst

A denitration catalyst and carrier-loaded technology, which is applied in the field of preparation of denitration catalysts, can solve the problems of catalyst denitration activity reduction, deactivation, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of a Ge-Mn-Ti carrier loaded V-Mo denitration catalyst, the steps are as follows:

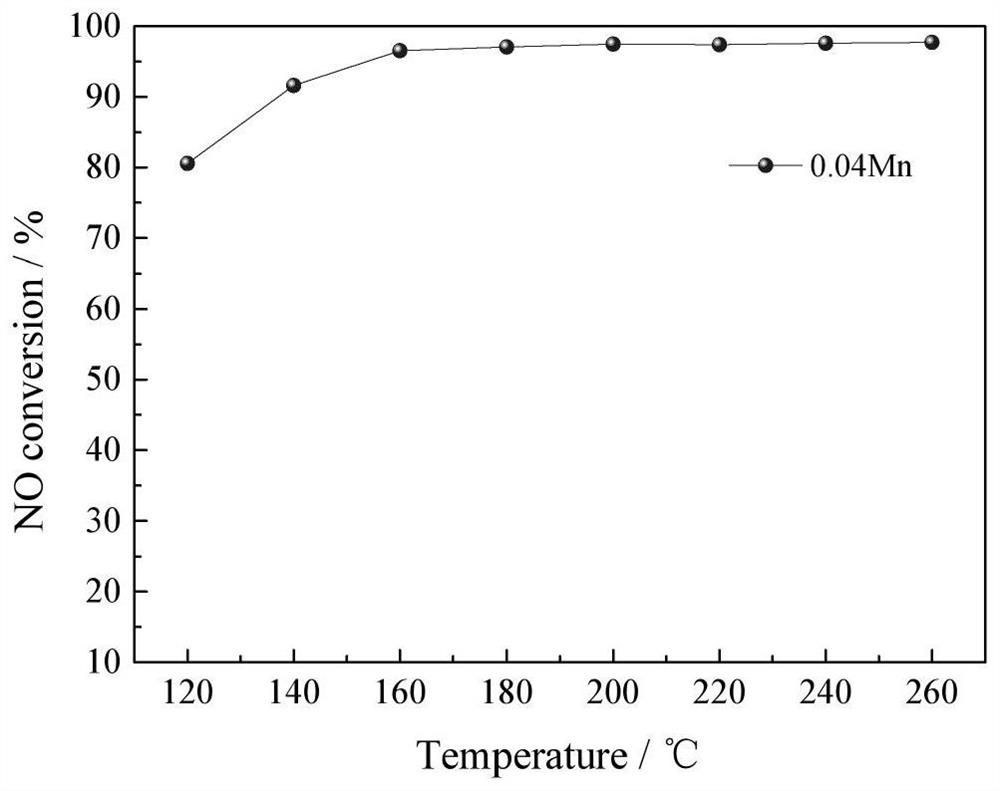

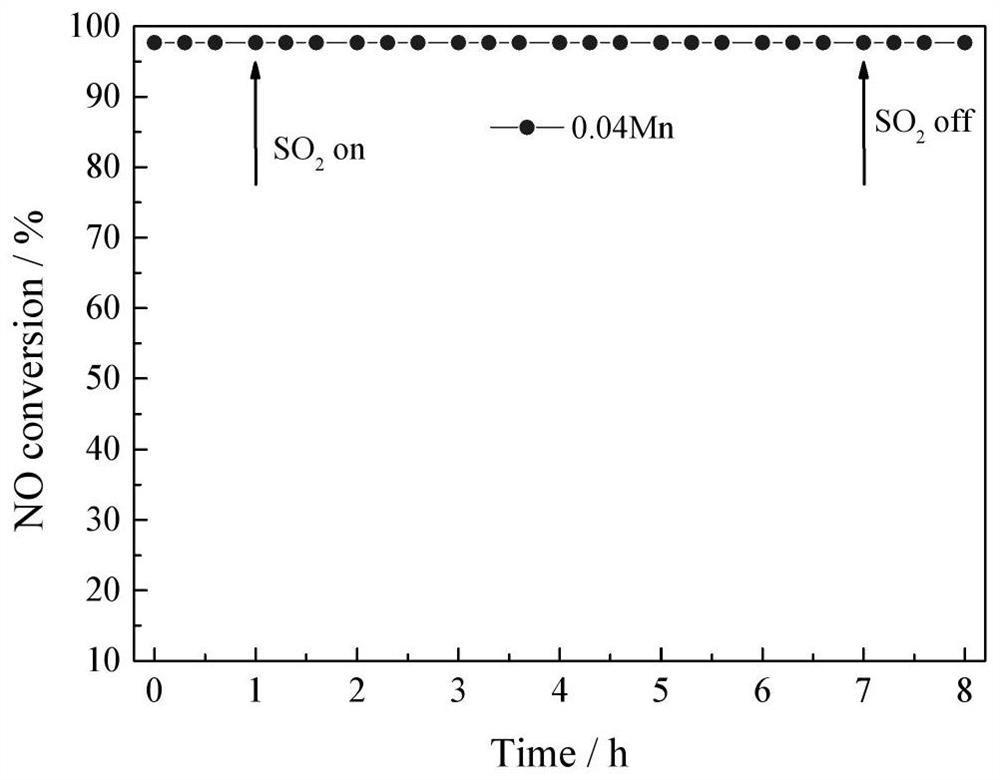

[0028] (1) Preparation of germanium manganese titanium (Ge-Mn-Ti) composite carrier: 10.0158g (according to 5gTiO 2 Calculate the amount of other substances) titanyl sulfate is completely dissolved in 100mL of deionized water, heated and stirred in a water bath at 60°C for 0.5h, and 0.0262g of germanium oxide is dissolved in 10mL of 3.5% ammonium bicarbonate aqueous solution to obtain GeO 2 Solution, 0.6140g manganese acetate (C 4 h 6 MnO 4 4H 2 O) be dissolved in 10mL deionized water to obtain manganese acetate solution, and slowly drop GeO2 into the flask through two titration funnels respectively. 2 (Ge:Ti=0.004:1) solution and manganese acetate (Mn:Ti=0.04:1) solution, then slowly add 30mL of ammonia water (25%) dropwise and keep stirring for 2h, so that the pH value of the solution is greater than 9, and the resulting precipitate Suction filtration and wash...

Embodiment 2

[0032]A preparation method of a Ge-Ti carrier loaded V-Mo denitration catalyst, the steps are as follows:

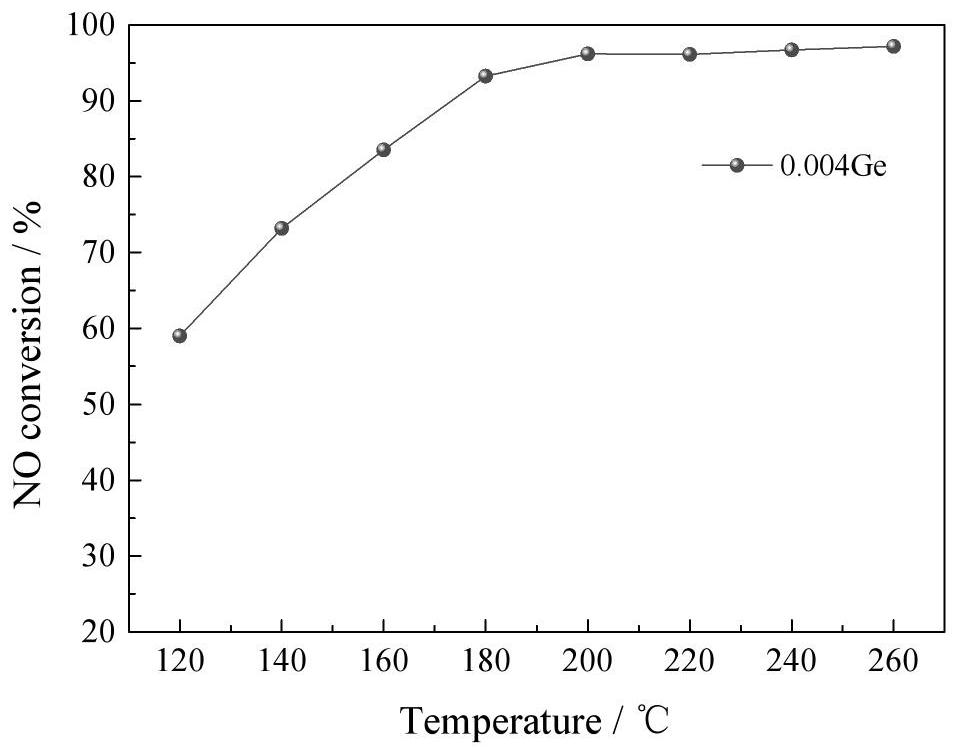

[0033] (1) Preparation of germanium-titanium (Ge-Ti) composite carrier: 10.0161g of titanium source (titanyl sulfate) was completely dissolved in 100mL of deionized water, heated and stirred in a water bath at 60°C for 0.5h, and 0.0263g of germanium oxide was dissolved in 3.5% ammonium bicarbonate in water to get GeO 2 Solution, slowly drop GeO into the flask through the titration funnel 2 Solution and ammonia solution (30mL, 25%) were stirred for 2h to make the pH value of the solution greater than 9, and the precipitate was suction-filtered and washed with deionized water until neutral to obtain a germanium-titanium composite precipitate, which was then dried in a drying oven at 120°C 12h, and then placed in an air atmosphere tube furnace at a constant temperature of 500°C for 4h to prepare a catalyst carrier. use N 2 The BET specific surface area of the carrier m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com