Moisture-proof refractory fiber spray coating and spraying method thereof

A refractory fiber and coating technology, applied in the field of refractory materials, can solve the problems of easy clogging of spraying equipment, single type of fiber, unreasonable fiber gradation, etc., and achieve the effect of improving strength and energy saving, reducing thermal conductivity, and improving moisture resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

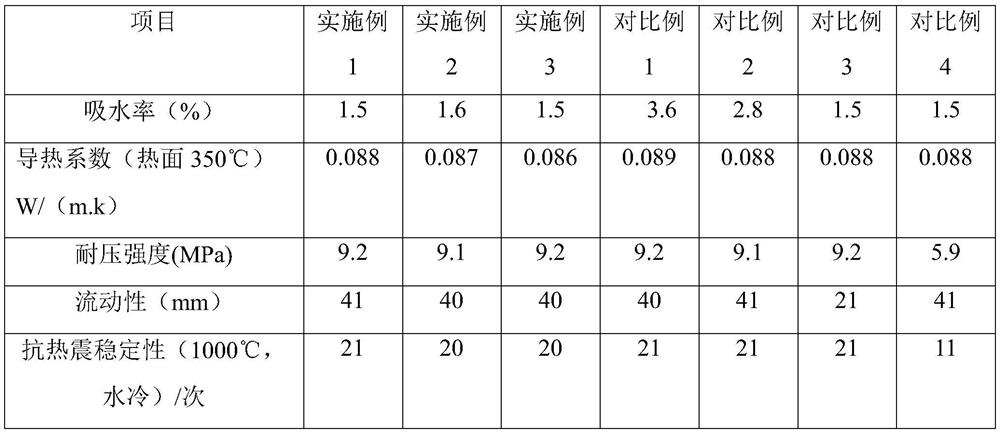

Examples

Embodiment 1

[0039] The moisture-proof refractory fiber spray coating is composed of the following components:

[0040] Refractory fiber 37wt.%; wood fiber 8wt.%; deionized water 25wt.%; inorganic binder 13wt.%; organic binder 0.6wt.%; inorganic powder 8wt.%; alumina hollow ball 4wt.%; Cr 2 o 3 Micropowder 4.4wt.%.

[0041] Among them, the refractory fiber is high alumina fiber; the inorganic binder is silica sol; the organic binder is polyacrylamide; the inorganic powder is a mixture of kaolin and silica powder; the mass ratio is 8:1.5; the particle size of the inorganic powder is 65 μm; The particle size of alumina hollow spheres is 0.4mm; Cr 2 o 3 The particle size of the fine powder is 3 μm.

[0042] The spraying method of described moisture-proof type refractory fiber spray coating is carried out according to the following steps:

[0043] S1: Put the refractory fiber and wood fiber into the fiber grinder and process them into short fibers with lengths of 15mm, 8mm and 2mm respect...

Embodiment 2

[0051] The moisture-proof refractory fiber spray coating is composed of the following components:

[0052] Refractory fiber 40wt.%; wood fiber 7wt.%; deionized water 28wt.%; inorganic binder 11wt.%; organic binder 0.3wt.%; inorganic powder 6wt.%; alumina hollow ball 4.2wt.%; Cr 2 o 3 Micropowder 3.5wt.%.

[0053] Among them, the refractory fiber is a mixture of high alumina fiber and glass fiber, and the mass ratio of the two is 2:1; the inorganic binder is sodium silicate; the organic binder is polyacrylamide; the inorganic powder is a mixture of kaolin and silica powder; The mass ratio is 9:2; the particle size of the inorganic powder is 70 μm; the particle size of the alumina hollow sphere is 0.2 mm; Cr 2 o 3 The particle size of the fine powder is 2.8 μm.

[0054] The spraying method of described moisture-proof type refractory fiber spray coating is carried out according to the following steps:

[0055] S1: Put the refractory fiber and wood fiber into the fiber grind...

Embodiment 3

[0063] The moisture-proof refractory fiber spray coating is composed of the following components:

[0064] Refractory fiber 43wt.%; wood fiber 6wt.%; deionized water 27wt.%; inorganic binder 12wt.%; organic binder 0.8wt.%; inorganic powder 3wt.%; alumina hollow ball 6wt.%; Cr 2 o 3 Micropowder 2.2wt.%.

[0065] Among them, the refractory fiber is zirconium-containing fiber; the inorganic binder is silica sol; the organic binder is acrylic resin; the inorganic powder is a mixture of kaolin and silicon micropowder; the mass ratio is 10:1; the particle size of the inorganic powder is 80 μm; The particle size of the aluminum hollow sphere is 0.5mm; Cr 2 o 3 The particle size of the fine powder is 4 μm.

[0066] The spraying method of described moisture-proof type refractory fiber spray coating is carried out according to the following steps:

[0067] S1: Put the refractory fiber and wood fiber into the fiber grinder and process them into short fibers with lengths of 10mm, 5mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap