Copper-zirconium-based amorphous powder for multiple damage repair, coating and preparation method

A damage repair and amorphous coating technology, which is applied in the field of preparation of copper-zirconium-based amorphous powder and copper-zirconium-based amorphous coating, can solve the problem of poor plastic deformation ability and amorphous formation of copper-zirconium-based amorphous alloys at room temperature Ability to limit the development and application, not suitable for the preparation of easy-to-crystallize copper-zirconium-based amorphous coatings, etc., to achieve the effect of ensuring full utilization, good glass forming ability, and high sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0030] The chemical composition of the copper-zirconium-based amorphous powder used for multiple damage repair of copper alloy parts of the present embodiment is:

[0031] (Cu 46-x Zr 47 Al 7 Ag x ) 100-y co y (x=0~4; y=0~1.5; x, y are at.%), x=3, y=0.5 in the present embodiment.

[0032] The specific chemical composition is: Cu 42.785at.%, Zr: 46.765at.%, Al: 6.965at.%, Ag: 2.985at.%, Co: 0.5at.%.

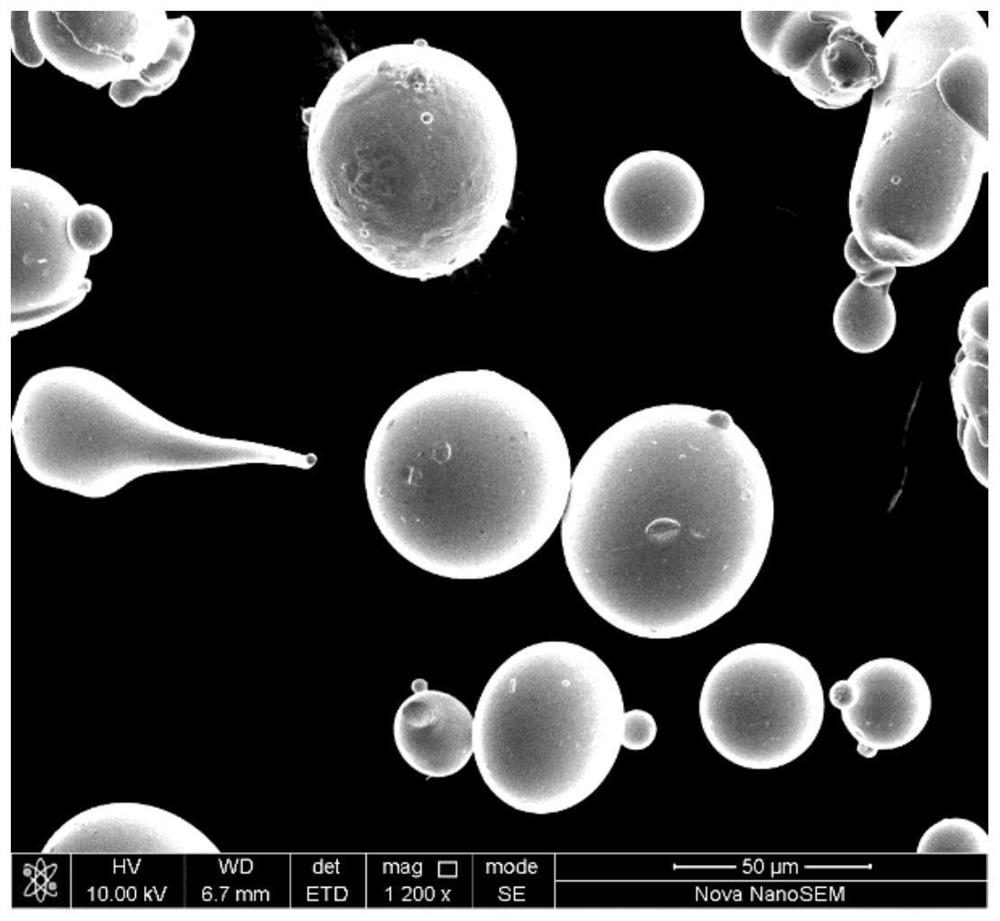

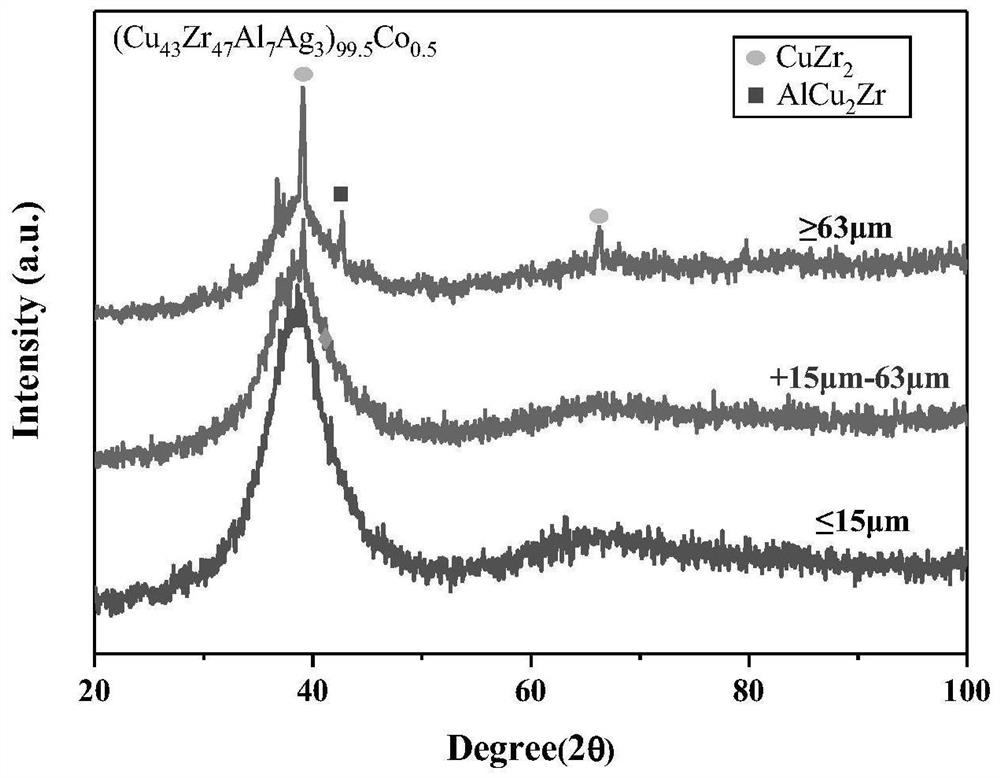

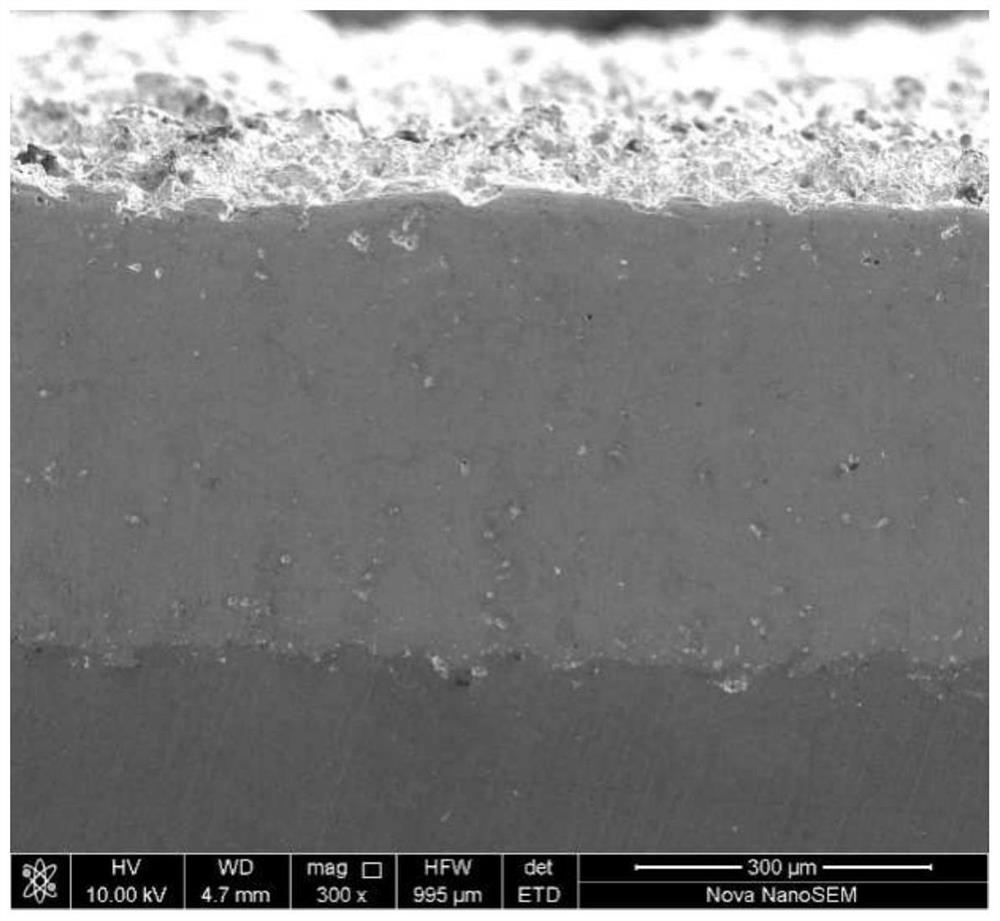

[0033] The scanning electron microscope photo of the above-mentioned copper-zirconium-based amorphous powder is shown in figure 1 , XRD pattern see figure 2 ; Powder particle size 15μm ~ 63μm, good fluidity, completely amorphous powder.

[0034] The preparation method of the copper-zirconium-based amorphous coating for multiple damage repair in this embodiment comprises the following steps:

[0035] ①Put the gas-atomized copper-zirconium-based amorphous powder with a particle size of 15 µm to 63 µm in an oven at 80°C for 3 hours.

[0036] ② Degreasing, derusting and san...

Embodiment 2)

[0046] The chemical composition of the copper-zirconium-based amorphous powder used for multiple damage repair of copper alloy parts of the present embodiment is:

[0047] (Cu 46-x Zr 47 al 7 Ag x ) 100-y co y (x=0~4; y=0~1.5; x, y are at.%), x=1, y=1 in this embodiment.

[0048] The preparation method of the coating is the same as in Example 1.

Embodiment 3)

[0050] The chemical composition of the copper-zirconium-based amorphous powder used for multiple damage repair of copper alloy parts of the present embodiment is:

[0051] (Cu 46-x Zr 47 al 7 Ag x ) 100-y co y (x=0~4; y=0~1.5; x, y are at.%), x=2, y=0.5 in the present embodiment.

[0052] The preparation method of the coating is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com