Flux growth method and application of large-size bismuth tungstate crystal

A growth method and crystal growth technology, which are applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of small light yield, etc., and achieve the effect of low price and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

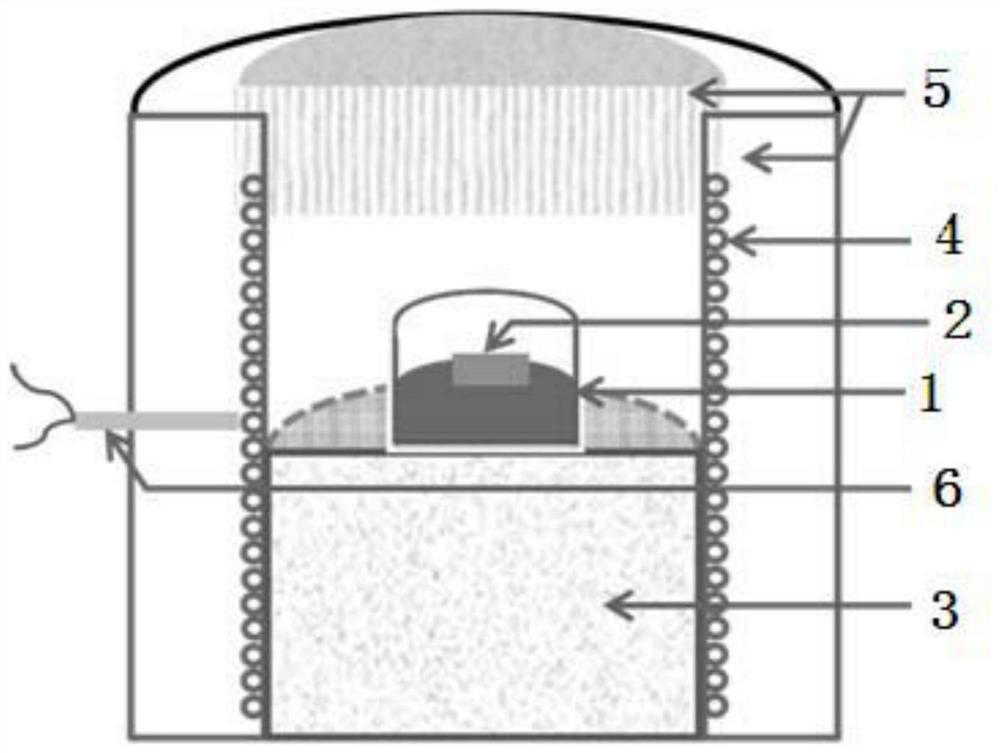

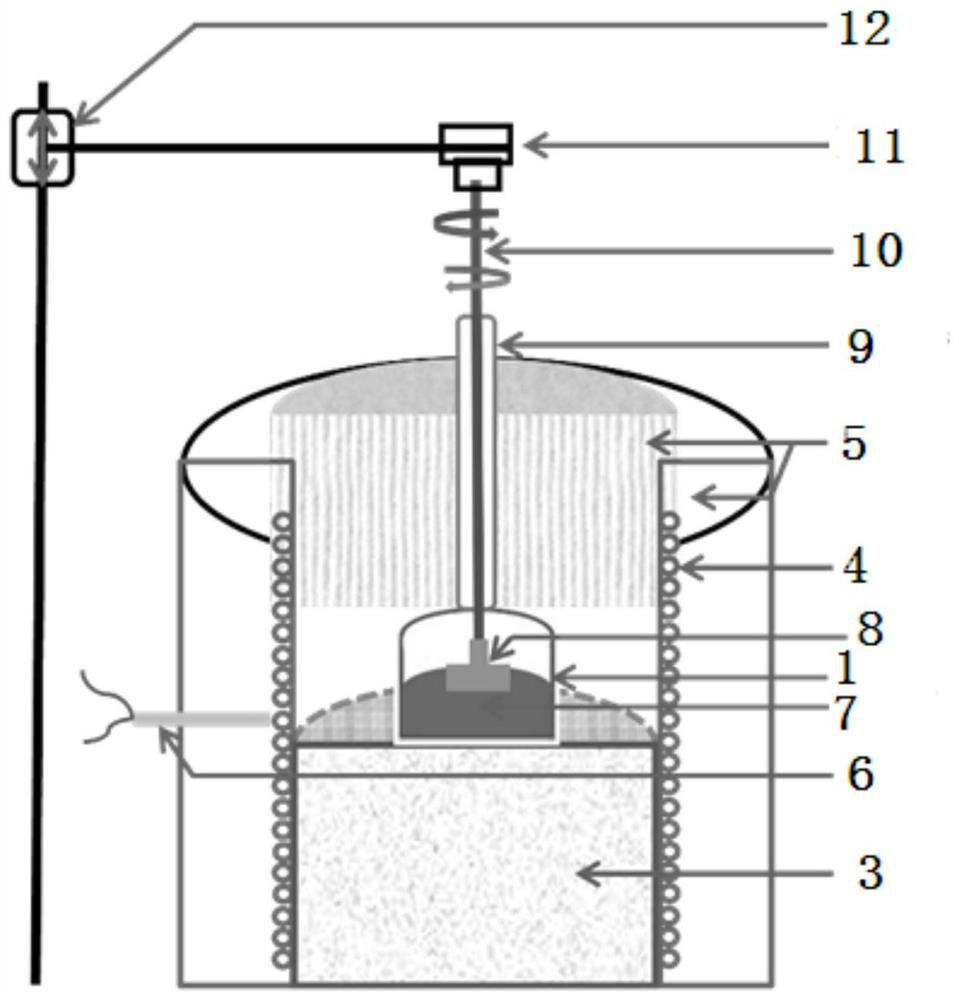

[0064] The present embodiment provides a flux growth method for large-size bismuth tungstate crystals, the method comprising the following steps:

[0065] Step S1, prefabrication of crystal growth material:

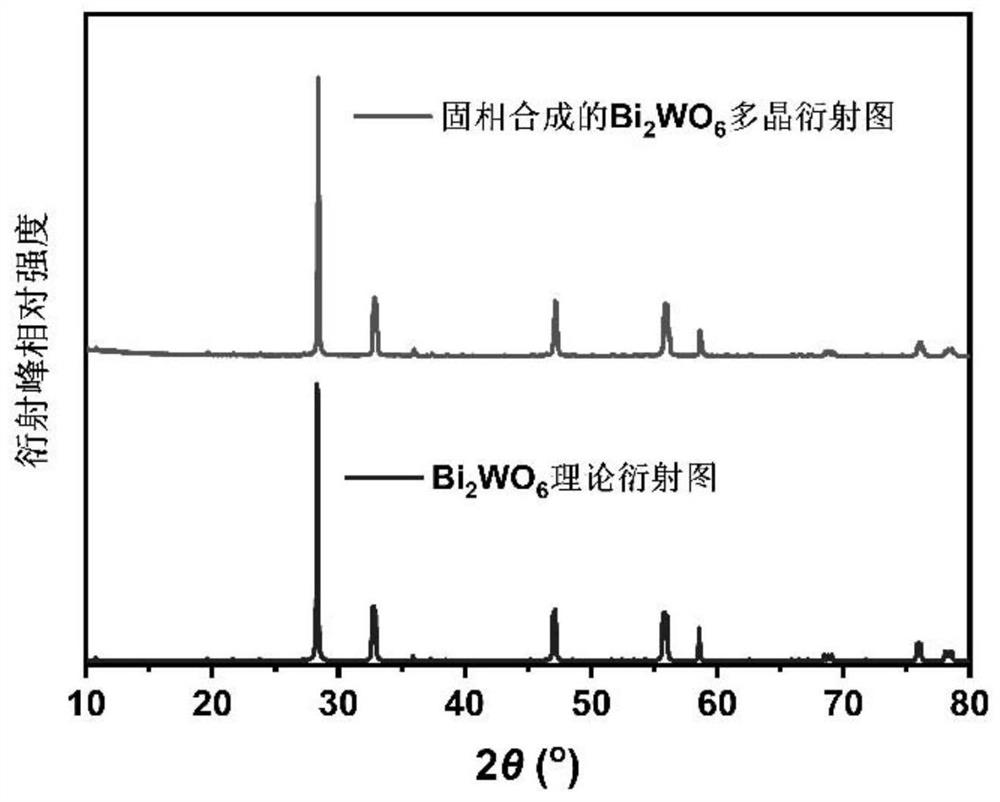

[0066] Bi 2 WO 6 polycrystalline synthesis. Bi 2 o 3 、WO 3 Proportion according to the stoichiometric ratio, after ball milling and full mixing, press on the press machine, transfer to the corundum crucible and sinter in the muffle furnace, the sintering temperature is 850°C, the sintering time is not less than 8 hours, and then the furnace is cooled to room temperature. Repeat grinding, mixing and sintering process no less than 2 times. Powder X-ray diffraction experiments were performed after grinding, such as image 3 As shown, the results are completely consistent with the theoretical diffraction pattern, without additional diffraction peaks, indicating that the Bi 2 WO 6 phase-pure polycrystals.

[0067] Step S2, flux growth of the target crystal:

[0068...

Embodiment 2

[0071] The prefabrication of the crystal growth material in step S1 is the same as that in Example 1.

[0072] Step S2, flux growth of the target crystal:

[0073] Bi 2 WO 6 seed crystal growth. With Li 2 B 4 o 7 -Bi 2 o 3 As a flux, Li in the flux 2 B 4 o 7 with Bi 2 o 3 The molar ratio is 1:0.5. The preparation method of the high-temperature homogeneous solution is the same as in Example 1. Lightly touch the platinum wire to the liquid surface, and by observing the temperature point where crystals are formed on the platinum wire during the cooling process, the saturation temperature of the crystals is accurately determined to be 873°C. After reheating to obtain a clear and homogeneous solution, the temperature was lowered to 873° C. for 10 hours and then kept at constant temperature for 5 hours. Using the single crystal obtained in Example 1 as the seed crystal, the temperature began to drop after lightly touching the liquid surface, and after 20 days of growt...

Embodiment 3

[0075] Bi 2 Mo 0.15 W 0.85 o 6 Crystal seed growth and crystal structure analysis. Bi was synthesized in the manner set forth in Example 1 2 Mo 0.15 W 0.85 o 6 polycrystalline, MoO during synthesis 3 Slightly overdose. With Li 2 B 4 o 7 -Bi 2 o 3 As a flux, Li in the flux 2 B 4 o 7 with Bi 2 o 3 The molar ratio is 1:0.5. The preparation method of the high-temperature homogeneous solution is the same as in Example 1. Lightly touch the platinum wire to the liquid surface, and by observing the temperature point where crystals are formed on the platinum wire during the cooling process, the saturation temperature of the crystals is accurately determined to be 855°C. After reheating to obtain a clear and homogeneous solution, the temperature was lowered to 855° C. for 10 hours and then kept at constant temperature for 5 hours. Using the single crystal obtained in Example 1 as the seed crystal, the temperature began to drop after lightly touching the liquid surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com