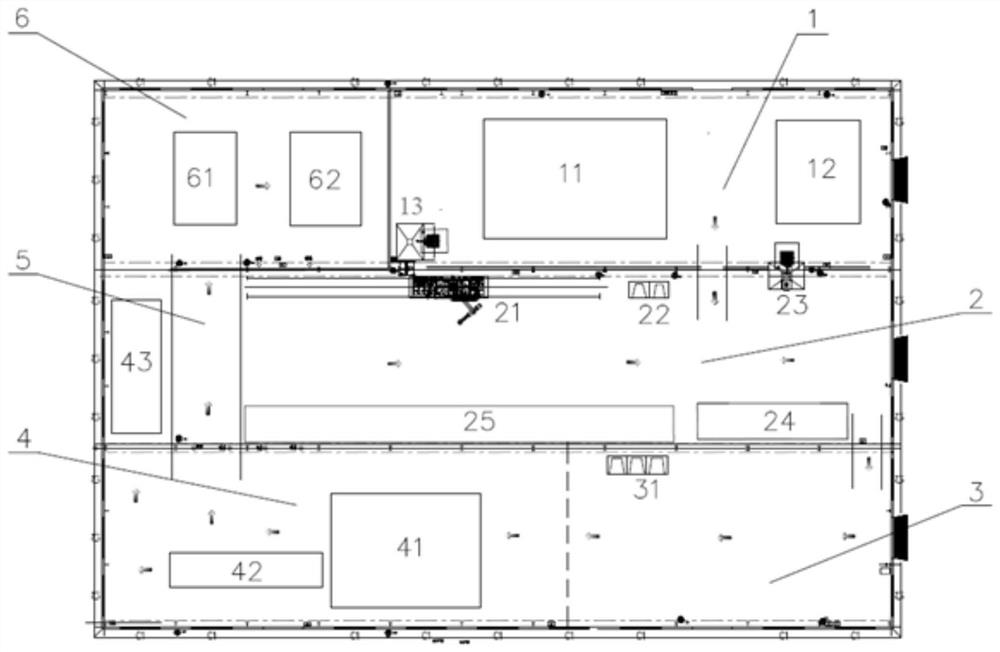

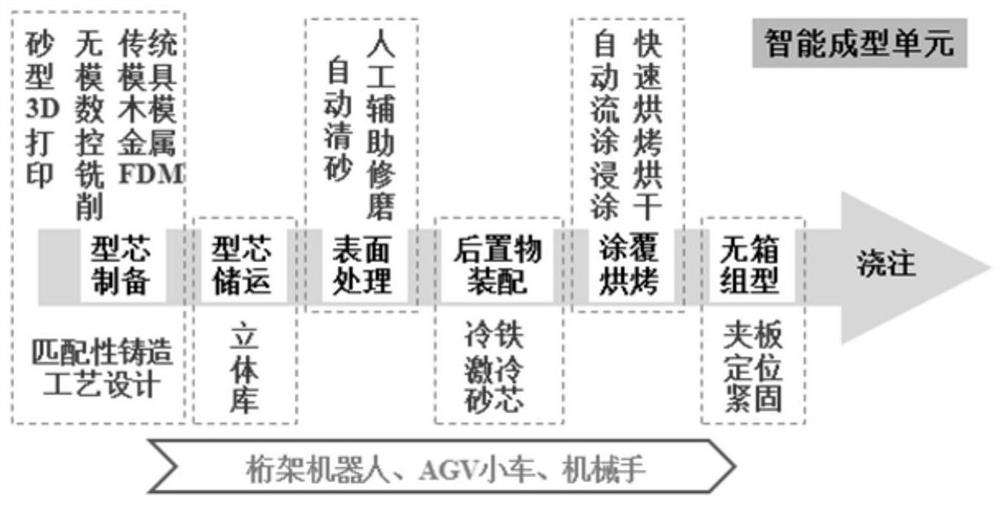

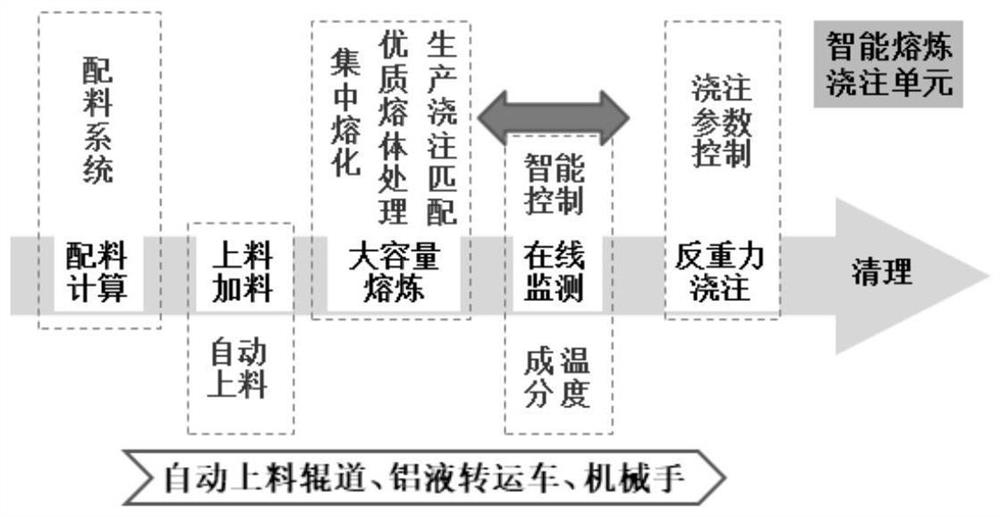

Aluminum alloy casting workshop and production scheduling method thereof

A technology of foundry and aluminum alloy, applied in foundry, mold shop, foundry equipment, etc., can solve problems such as capacity bottleneck, gap between production automation and intelligence, and key process links have not been fully opened up, achieving strong applicability , the effect of reducing labor intensity and improving circulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0159] Shell 1, a simple cylindrical casting, with a diameter of 400mm and a height of 700mm, has been mass-produced, with a production quantity of 100 pieces. The specific process flow is as follows:

[0160] Use mold making → mobile sand mixer to mix sand to form cores → box closing → smelting and pouring → mold cooling → falling sand cleaning.

[0161] Figure 4 It is the production process and workshop production flow chart of Example 1.

Embodiment 2

[0163] Shell 2, complex casting with special-shaped curved surface, height 1500mm, new product, the production quantity is 15 pieces. The specific process flow is as follows:

[0164] Using sand 3D printing modeling → box closing → smelting and pouring → mold cooling → falling sand cleaning.

[0165] Figure 5 It is the production process and workshop production flow chart of Example 2.

Embodiment 3

[0167] Shell 3, complex casting, the size is 500mm×800mm×1000mm, the local performance requirements are high, and the production quantity is 10 pieces. The specific process flow is as follows:

[0168] The combination of sand 3D printing and sand CNC cutting is used to manufacture → box closing → smelting and pouring → mold cooling → falling sand cleaning.

[0169] Image 6 It is the production process and workshop production flow chart of Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com