Zirconium oxide-based metal texture crystal diamond material, ceramic tile and preparation method of ceramic tile

A zirconia and base metal technology, applied in the field of ceramic tiles, can solve the problems of high temperature resistance and inertness, unstable metallic luster, etc., achieve good stability, solve the effect of unstable metallic luster and strong inertness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Preparation of green fragmented zirconia-based metallic diamond material:

[0089] After mixing 85 parts of zirconia powder, 2 parts of chromium oxide and 3 parts of magnesium oxide, a mixed powder was obtained;

[0090] Mix 40 parts of mixed powder, 7.5 parts of polyvinyl butyral, 1.5 parts of polyethanol alkyl ether, 3 parts of fatty acid, and 40 parts of toluene to make a slurry, add the slurry to the hopper of the casting machine, The thickness is controlled by a scraper, and it is conveyed out through the feeding nozzle to form a thin-layer blank on the conveyor belt of the casting machine. After the solvent is gradually volatilized, it is punched to obtain a sheet-like blank;

[0091] The flake-shaped green body is sintered at 1450° C. for 3 hours, then polished and crushed to obtain a green fragmented zirconia-based metal texture crystal diamond material.

[0092] Preparation of ceramic tiles with green flaky metallic texture crystal diamond sparkle effect:

[...

Embodiment 2

[0111] Preparation of blue granular zirconia-based metallic diamond material:

[0112] After mixing 85 parts of zirconia powder, 2 parts of cobalt oxide and 3 parts of magnesium oxide, a mixed powder was obtained;

[0113] 40 parts of mixed powder, 7.5 parts of cellulose acid butylene, 1.5 parts of dibutylphthalic acid, 3 parts of benzenesulfonic acid, and 40 parts of toluene were mixed uniformly, and pressed into a block-shaped body by using a press;

[0114] The block green body was sintered at 1450 ℃ for 3 hours for crushing treatment, and the blue granular zirconia-based metal texture crystal diamond material with metallic texture was obtained.

[0115] Preparation of ceramic tiles with blue granular metallic texture crystal diamond sparkle effect:

[0116] (1) Provide ceramic tile body;

[0117] (2) The bottom glaze slurry is 600g / m2 2 The amount of glazing applied is poured onto the surface of the ceramic tile body, and after drying, the ceramic tile body with bottom ...

Embodiment 3

[0134] Preparation of ceramic tiles with green flaky metal texture crystal diamond flash effect and blue granular metal texture crystal diamond flash effect at the same time:

[0135] (1) Provide ceramic tile body;

[0136] (2) Make the bottom glaze slurry at 550g / m2 2 The amount of glazing applied is poured onto the surface of the ceramic tile body, and after drying, the ceramic tile body with bottom glaze decoration is obtained;

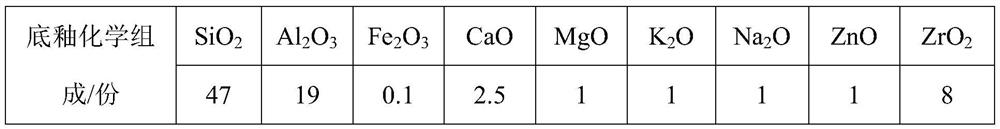

[0137] Wherein, by weight, the chemical composition of the bottom glaze is as shown in Table 9:

[0138] The chemical composition of the bottom glaze in the embodiment 3 of table 9

[0139]

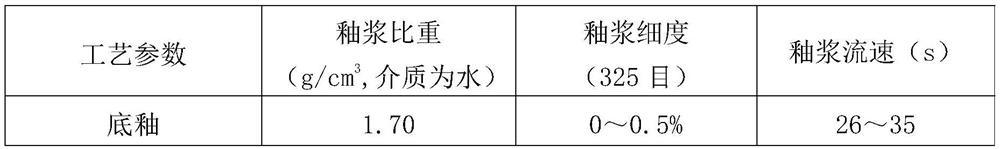

[0140] The process parameters of the base glaze paste are shown in Table 10:

[0141] The process parameters of the bottom glaze slurry in the embodiment 3 of table 10

[0142]

[0143] (3) mixing the green flaky zirconia-based metal texture crystal diamond material in Example 1 and the blue granular zirconia-based metal texture crystal diamond mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com