Pigment yellow 139 synthesis process

A synthesis process and a technology for pigment yellow, applied in the field of pigment production, can solve the problems of complex production process route of phthalonitrile, environmental protection, large safety impact, insufficient product supply, etc., to avoid a large amount of waste acid water and save a lot of The effect of energy consumption and shortening of process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Pigment Yellow 139 synthesis process, including the following steps:

[0031] (1) The use of solid melting method to use batch or continuous or batch and continuous combination of phthalic anhydride and urea, under the action of the catalyst to synthesize 1,3-diiminoisoindoleline,

[0032] (2) The crude pigment Yellow 139 was synthesized by the reaction of 1,3-diiminoisoindoleline with barbiturate acid.

[0033] The steps described (1) are specifically:

[0034] Urea, ammonium salts were added to the reactor, heated to melt and then a catalyst was added, dehydrated at 120-135 °C for 2 to 3 hours, phthalic anhydride was added after dehydration, and the iminoline reaction was carried out at 130 ~150 °C for 3 hours, and the heating was continued to 160 ~ 180 ° C for 5 to 7 hours for condensation, and after the condensation was completed, the cooling was reduced to 60 ° C or less, and the water was added to add sodium hydroxide, until the material dissolution was dissolved and d...

Embodiment 2

[0042] Pigment Yellow 139 synthesis process, including the following steps:

[0043] (1) The use of solid melting method to use batch or continuous or batch and continuous combination of phthalic anhydride and urea, under the action of the catalyst to synthesize 1,3-diiminoisoindoleline,

[0044](2) The crude pigment Yellow 139 was synthesized by the reaction of 1,3-diiminoisoindoleline with barbiturate acid.

[0045] The steps described (1) are specifically:

[0046] Urea, ammonium salts were added to the reactor, heated to molten after the catalyst was added, dehydrated at 120-135 ° C for 2 to 3 hours, phthalic anhydride was slowly added to the above reactor after dehydration, and the iminoidation reaction was carried out at 130 ~ 150 ° C for 3 hours, and the heating was continued to 160 ~ 180 ° C for 5 to 7 hours of condensation, and after the condensation was completed, the vacuum was evacuated and cooled below 60 ° C, and the 1,3-diiminoisoindoline was adhered to the molten c...

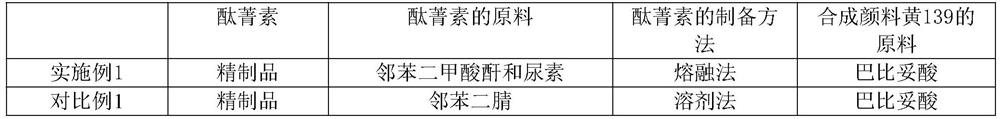

Embodiment 1 and comparative example 1

[0081] (2) Example 1 compared to the counter-proportional 1:

[0082]Example 1: 1,3-Diiminoisoindole is dissolved in an alkaline methanol solution, facilitating the reaction; In particular, the reaction system is methanol and a large number of anhydrous solvents are added, with the distillation of methanol, the residual acidic wastewater is very small, and after separation by pressure filtration, the amount of waste liquid produced is small and easy to treat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com