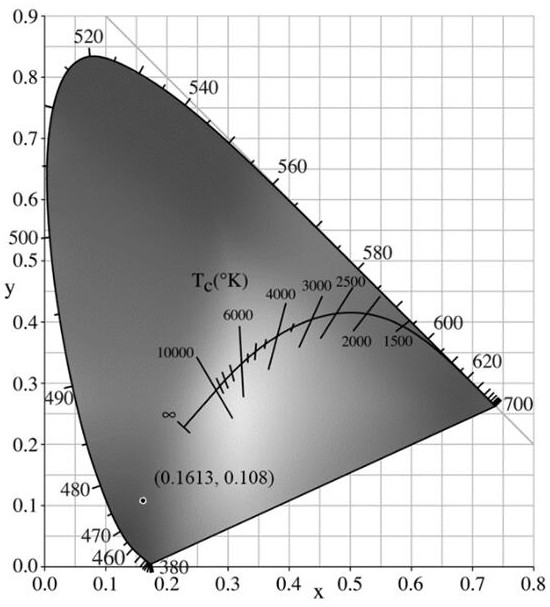

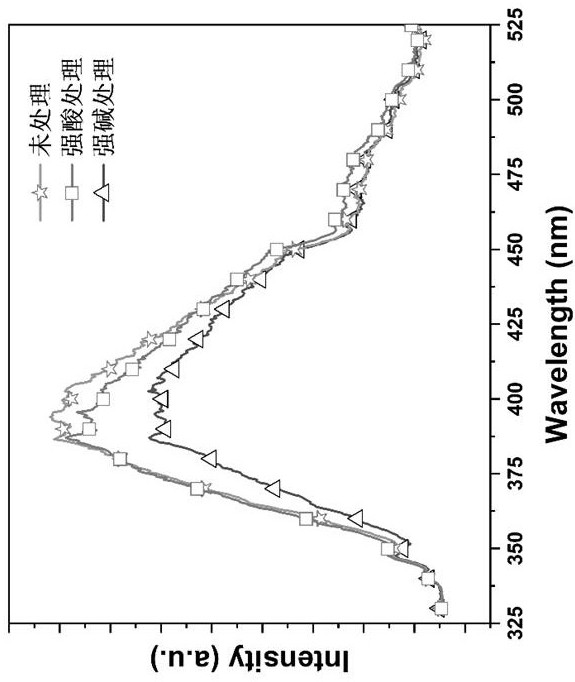

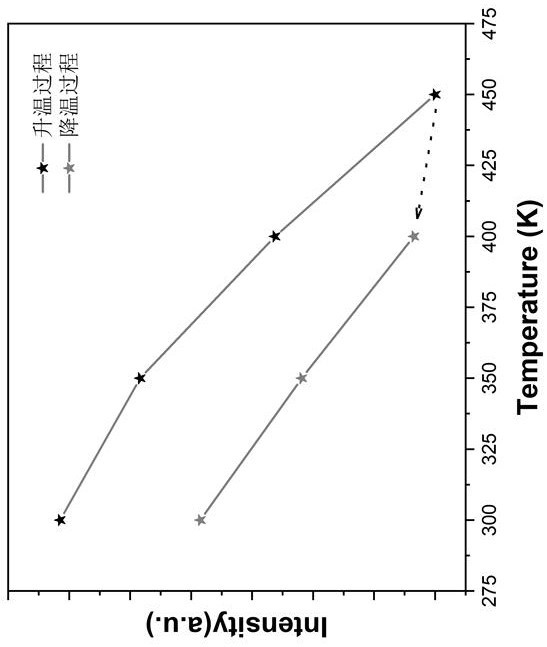

Method for obtaining acid-resistant and alkali-resistant blue fluorescent powder by coating 5-sulfosalicylic acid with barium sulfate

A technology of sulfosalicylic acid and blue phosphor, which is applied in chemical instruments and methods, luminescent materials, agricultural machinery and equipment, etc., can solve difficult problems and achieve the effect of simple method, low cost and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

Step 1: According to H 3 SSA and BaSO 4 The coating is in a molar ratio of 1:3, using an analytical balance to weigh a predetermined amount (eg 0.254g, (0.001 mol)) of H 3 SSA, predetermined amount (0.24 g, (0.006 mol)) NaOH, predetermined amount (0.426 g, (0.003 mol)) Na 2 SO 4 , a predetermined amount (eg 0.625 g, (0.003 mol)) BaCl 2 as a raw material.

[0018] Step 2: Put H 3 Put SSA in a beaker, measure 20 mL of deionized water, add it to the beaker, and use magnetic stirring to completely dissolve the drug to obtain a clear and transparent solution; mix NaOH, Na 2 SO 4 , BaCl 2 They were placed in beakers, respectively, and 20 mL of a predetermined amount of deionized water were added to dissolve the drug completely using the same method, and then prepared into a predetermined amount (20 mL, 0.3 mol / L) of NaOH solution, and a predetermined amount (20 mL, 0.15 mol) of NaOH solution. / L)Na 2 SO 4 solution and a predetermined amount (20 mL, 0.15 mol / L) of BaCl 2 so...

Embodiment 2

Step 1: According to H 3 SSA and BaSO 4 The coating is in a molar ratio of 1:4, and a predetermined amount (such as 0.254g, (0.001 mol)) of H is weighed using an analytical balance. 3 SSA, predetermined amount (0.24g, (0.006 mol)) NaOH, predetermined amount (0.568g, (0.004 mol)) Na 2 SO 4 , a predetermined amount (eg 0.833 g, (0.004 mol)) BaCl 2 as a raw material.

[0023] Step 2: Put H 3 Put SSA in a beaker, measure 20 mL of deionized water, add it to the beaker, and use magnetic stirring to completely dissolve the drug to obtain a clear and transparent solution; mix NaOH, Na 2 SO 4 , BaCl 2 They were placed in beakers, respectively, and 20 mL of a predetermined amount of deionized water were added to dissolve the drug completely using the same method, and then prepared into a predetermined amount (20 mL, 0.30 mol / L) of NaOH solution, a predetermined amount (20 mL, 0.20 mol / L) of NaOH solution. / L)Na 2 SO 4 solution and a predetermined amount of (20 mL, 0.20 mol / L) B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com