Interconnected flexible nano silicon composite powder as well as preparation method and application thereof

A composite powder, interconnected and flexible technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve problems such as poor cycle stability and poor electrical conductivity, and achieve improved negative electrode capacity and improved Effects of electrochemical cycle stability, improved conductivity, and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

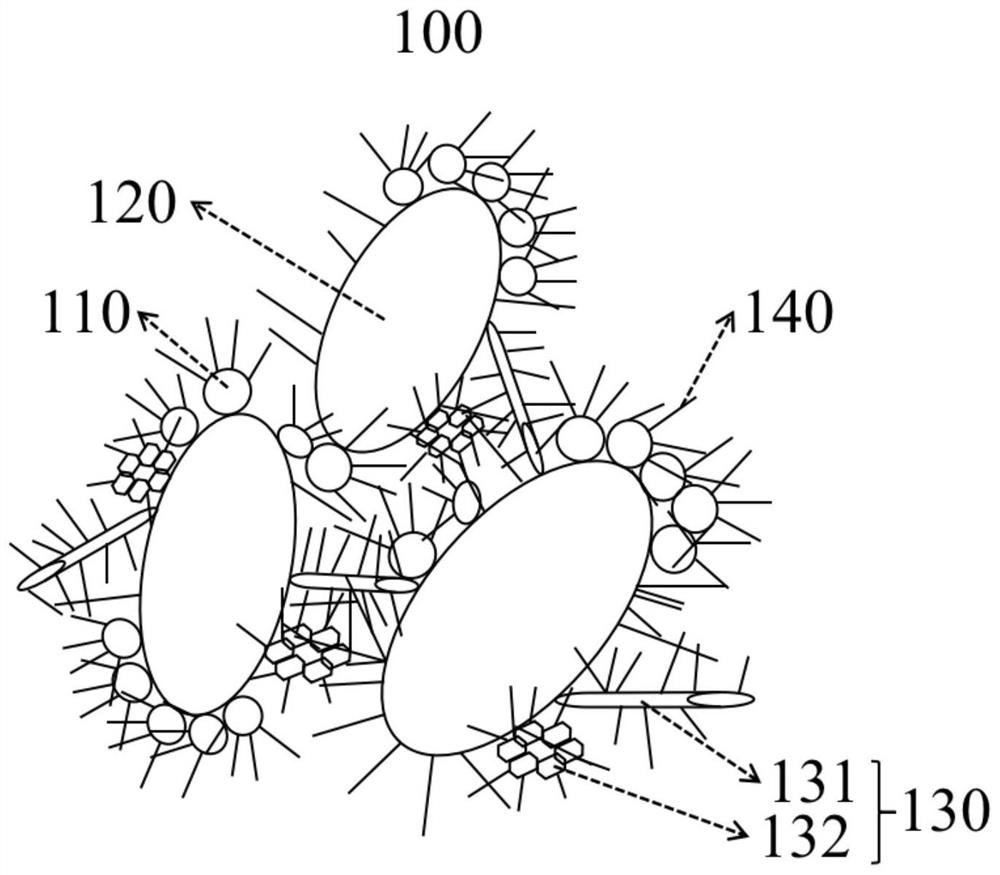

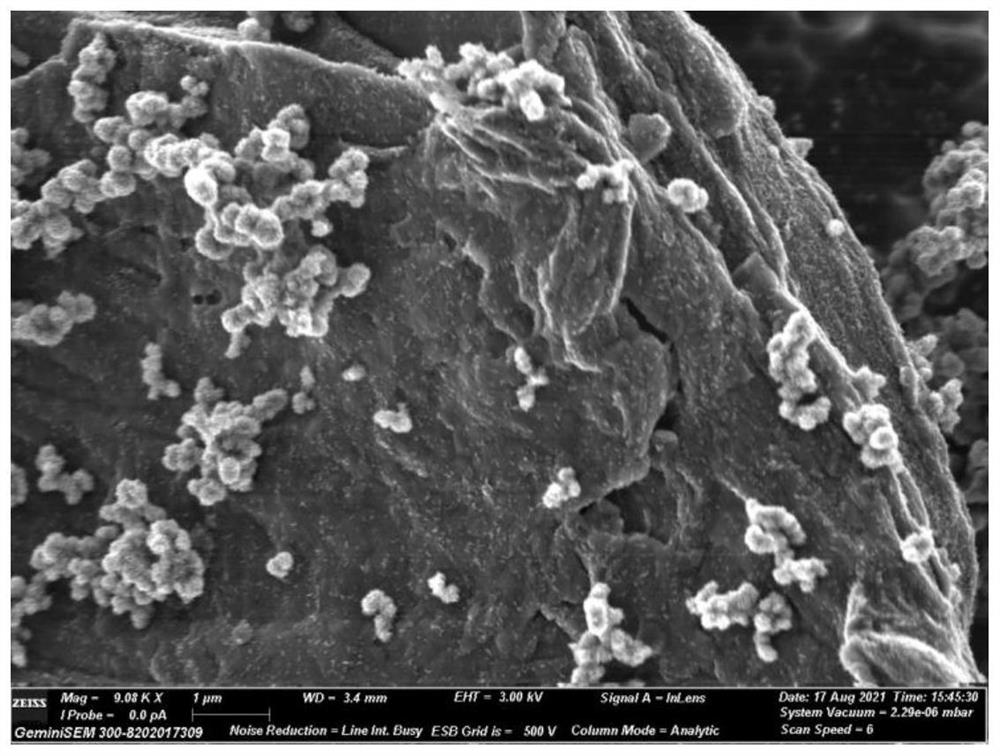

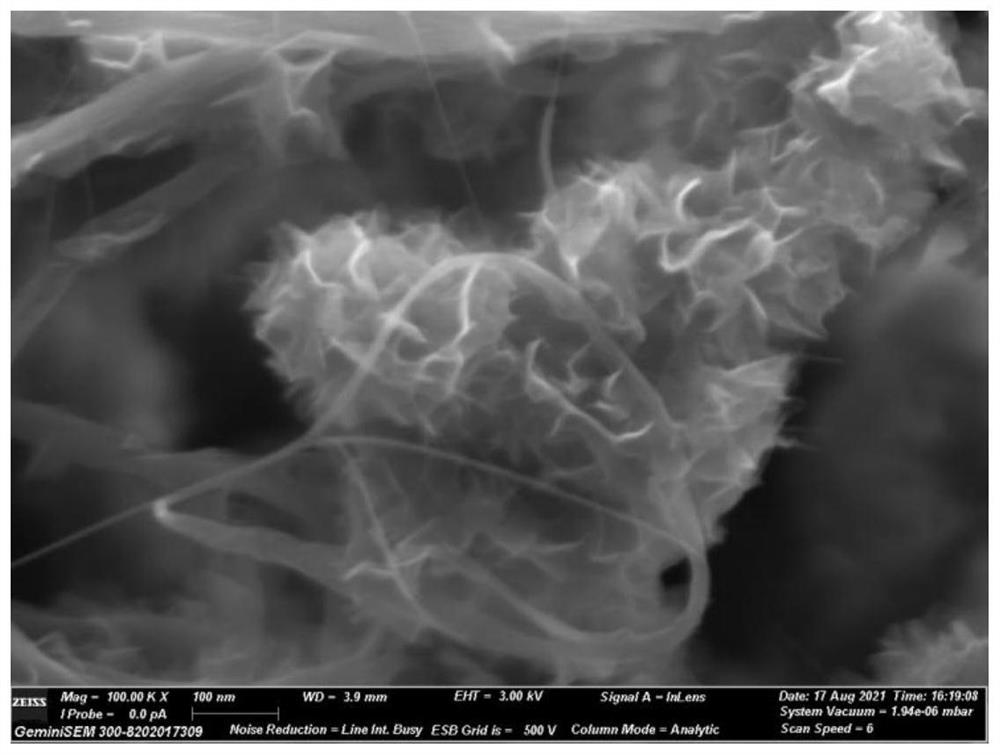

[0041] The present application also provides a method for preparing the above-mentioned interconnected flexible nano-silicon composite powder, which includes first preparing a composite matrix, and then forming a graphene layer with vertical graphene sheets on the surface of the composite matrix. Specifically, the preparation method of the interconnected and flexible nano-silicon composite powder includes: firstly mixing nano-scale silicon powder, micro-scale graphite powder and nano-scale carbon material to prepare a composite matrix; graphene sheets.

[0042] The vertical graphene sheets prepared by chemical vapor deposition have good crystallinity, which is beneficial to improve the conductivity and flexibility of the graphite layer.

[0043] In the embodiment of the present application, the step of preparing the composite matrix includes: dissolving nano-scale silicon powder, micro-scale graphite powder, nano-scale carbon material and dispersant in a solution, mixing unifo...

Embodiment 1

[0062] This embodiment provides an interconnected flexible nano-silicon composite powder and a preparation method thereof, comprising the following steps:

[0063] (1) 50g of silicon powder with D50 of 50nm, 24g of carbon nanotubes with D50 of 10nm, 1g of graphene powder with D50 of 10μm, 510g of graphite powder with D50 of 15μm and 14g of polyvinylpyrrolidone were added to 2000ml in anhydrous ethanol, stir and disperse evenly and then dry to obtain a composite matrix;

[0064] (2) placing the composite matrix obtained in step (1) in a tube furnace, and heating up to 1050°C at 10°C / min under an argon protective atmosphere;

[0065](3) under the temperature condition of step (2), pass methane at 20mL / min and pass hydrogen at 80mL / min, close the protective gas, keep the temperature for 4h, close the methane and hydrogen, open the protective gas, and then naturally cool to room temperature to obtain Interconnected flexible nano-silicon composite powder.

Embodiment 2

[0067] This embodiment provides an interconnected flexible nano-silicon composite powder and a preparation method thereof, comprising the following steps:

[0068] (1) Add 50g of silicon powder with D50 of 30nm, 16g of carbon nanotubes with D50 of 10nm, 110g of graphite powder with D50 of 15μm and 10g of citric acid into 800ml of absolute ethanol, stir and disperse evenly and then bake dry to obtain a composite matrix;

[0069] (2) placing the composite matrix obtained in step (1) in a tube furnace, and heating up to 1000°C at 10°C / min under an argon protective atmosphere;

[0070] (3) under the temperature condition of step (2), pass methane at 20mL / min and pass hydrogen at 40mL / min, close the protective gas, keep the temperature for 3h, close the methane and hydrogen, open the protective gas, and then naturally cool to room temperature to obtain Interconnected flexible nano-silicon composite powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com