Method for flotation of copper from low-grade copper sulfide ore with high pyrrhotite content

A pyrite, low-grade technology, applied in flotation, process efficiency improvement, solid separation, etc., can solve the problems of high copper loss rate, low copper recovery rate, etc., to reduce adverse effects, high product quality, production The effect of process stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

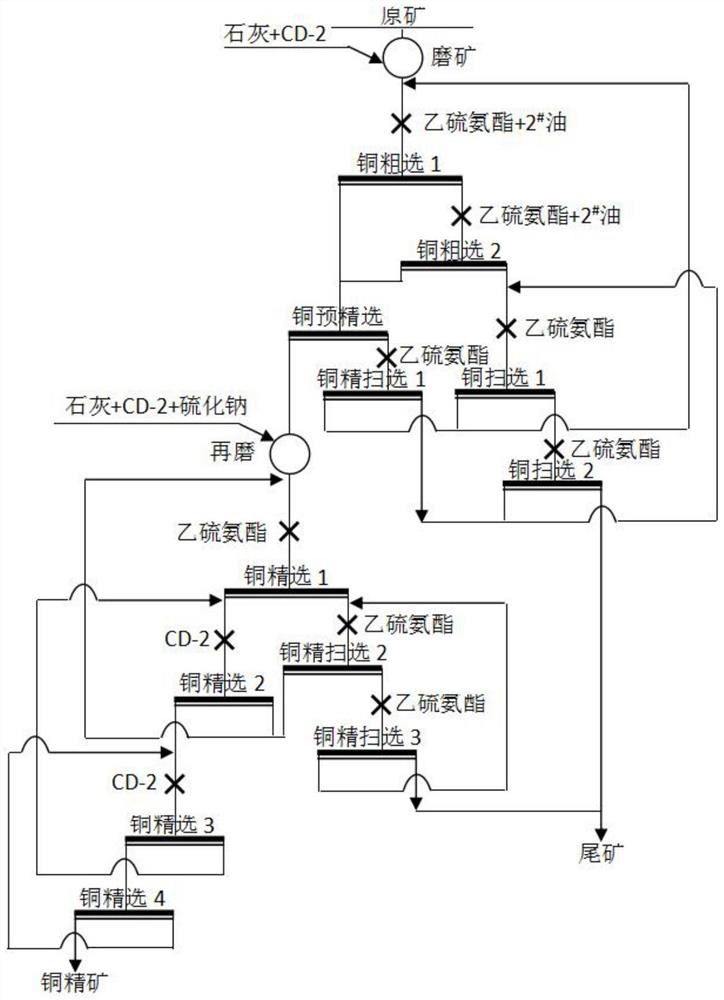

Image

Examples

Embodiment 1

[0051] This embodiment provides a method for flotation of copper from low-grade and high-pyrrhotite copper sulfide ore, the raw ore used is high-pyrrhotite copper sulfide ore, containing 1.11% chalcopyrite, Iron ore 39.91%, pyrite 6.44%; specifically including the following steps:

[0052] S1. Crushing the high pyrrhotite copper sulfide ore to obtain ore powder, adding 2000g / t lime and 300g / t CD-2 inhibitor for wet grinding during the grinding process, so that the particle size in the ore powder is less than 0.074mm The solid particles of the ore powder account for 75% of the mass of the ore powder, and water is added to adjust the slurry concentration to 33% to obtain a primary ore slurry;

[0053] S2, add 42g / t of ethyl thiourethane, 4g / t of 2# oil to the primary pulp of step S1 to carry out the first copper roughing to obtain a rough concentrate and a roughing tailings; to a roughing Add 18g / t of ethyl thiocarbamate and 4g / t of 2# oil to the tailings for the second copper ...

Embodiment 2

[0085] This embodiment provides a method for flotation of copper from low-grade and high-pyrrhotite copper sulfide ore, the raw ore used is high-pyrrhotite copper sulfide ore, containing 1.08% chalcopyrite, 40.75% of iron ore, 5.98% of pyrite; compared with Example 1, the difference is that the dosage of the agents in each step is adjusted, as follows; the rest are roughly the same as Example 1, and will not be repeated here.

[0086] In step S1, adding 1500g / t lime and 400g / t CD-2 inhibitor for wet grinding,

[0087] In step S2, add 40g / t thiocarbamate, 3g / t 2# oil to carry out the first copper roughing, add 15g / t thiocarbamate, 3g / t 2# oil to carry out the second Secondary copper rough selection;

[0088] In step S3, add 2g / t of thiocarbamate to carry out the first copper sweep, and add 2g / t of thiocarbamate to carry out the second copper sweep;

[0089] In step S4, add 2g / t of thiourethane to carry out a copper fine sweep;

[0090] In step S5, add 200g / t lime, 120g / t CD-...

Embodiment 3

[0097] This embodiment provides a method for flotation of copper from low-grade and high-pyrrhotite copper sulfide ore. The raw ore used is high-pyrrhotite copper sulfide ore containing 1.23% chalcopyrite and Iron ore 30.46%, pyrite 13.75%; compared with Example 1, the difference is that the concentration of the primary slurry in step S1 and the mass percentage of ore with a particle size of less than 0.074mm in step S1 are adjusted, and step S5 is less than 0.038 The mass percentage of the ore of mm, the dosage of the medicament in each step, are as follows; the rest are roughly the same as in Example 1, and will not be repeated here.

[0098] In step S1, 3000g / t lime and 200g / t CD-2 inhibitor are added for wet grinding, so that the solid particles with a particle size of less than 0.074mm in the mineral powder account for 70% of the mass of the mineral powder, and water is added to adjust the slurry concentration to 31%;

[0099] In step S2, add 45g / t thiocarbamate, 5g / t 2#...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com