Welding method and system for reducing laser welding heat affected zone and refining structure

A laser welding and heat-affected zone technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem that the uniformity and performance consistency of large-thickness welded joints cannot be guaranteed, and the oscillating laser tuning energy field is not used. Unable to meet the problems of one-time forming of medium and thick plates, to achieve the effect of optimizing and regulating laser welding forming and quality, improving the uniformity of structure and properties, and improving welding stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

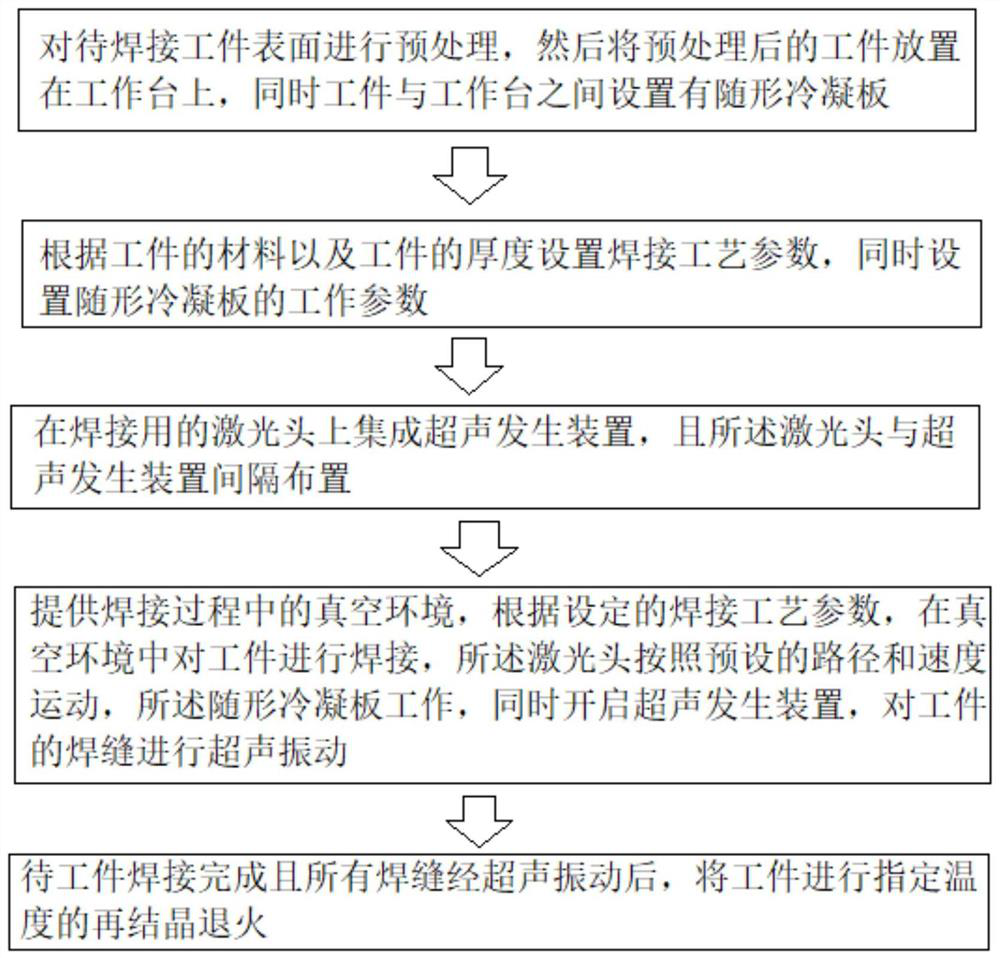

[0072] Step 1: During welding, CO2 gas lasers, YAG solid-state lasers, semiconductor lasers, and fiber lasers can be used as lasers.

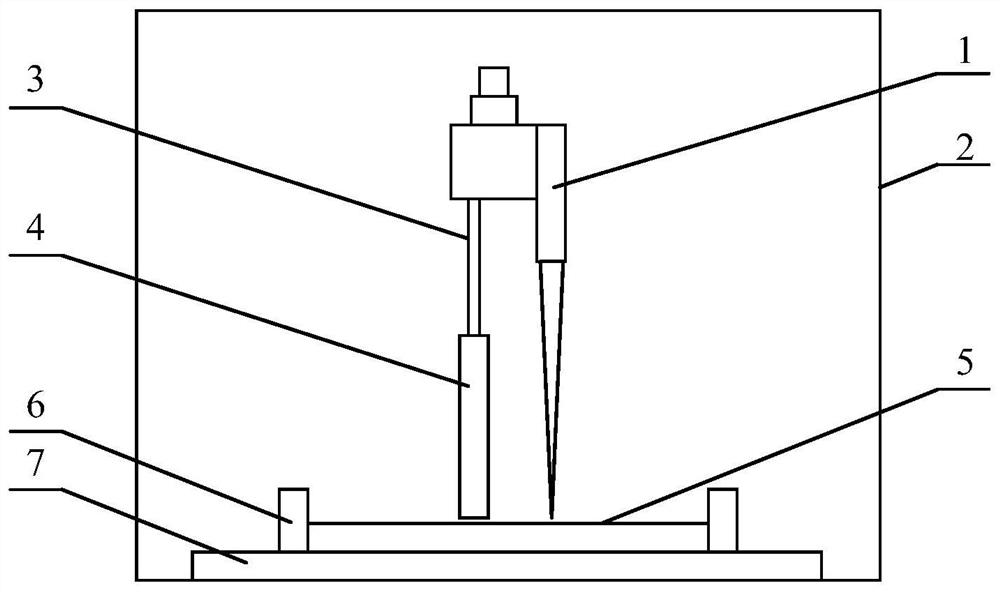

[0073]Step 2: Fix the polished or cleaned workpiece 5 on the welding fixture 6, and place it on the workbench in the vacuum chamber 2, and the workbench is equipped with a conformal condenser plate 7.

[0074] Step 3: Fix the ultrasonic generating device 4 on the laser head 1 with a special fixture 3, so that after the laser welding is completed, it can realize the ultrasonic vibration impact after welding by controlling the laser head without light output.

[0075] Step 4: Evacuate the vacuum chamber 2, and the vacuum pressure is 100-10000Pa.

[0076] Step 5: Vacuum laser welding, specifically:

[0077] S51: According to the thickness of the workpiece 5 to be welded, the laser power is 3500-5500 W, the welding speed is 0.3-1.8 m / min, and the defocusing amount is -10-10 mm.

[0078] S52: the temperature range of the conformal condensing plate...

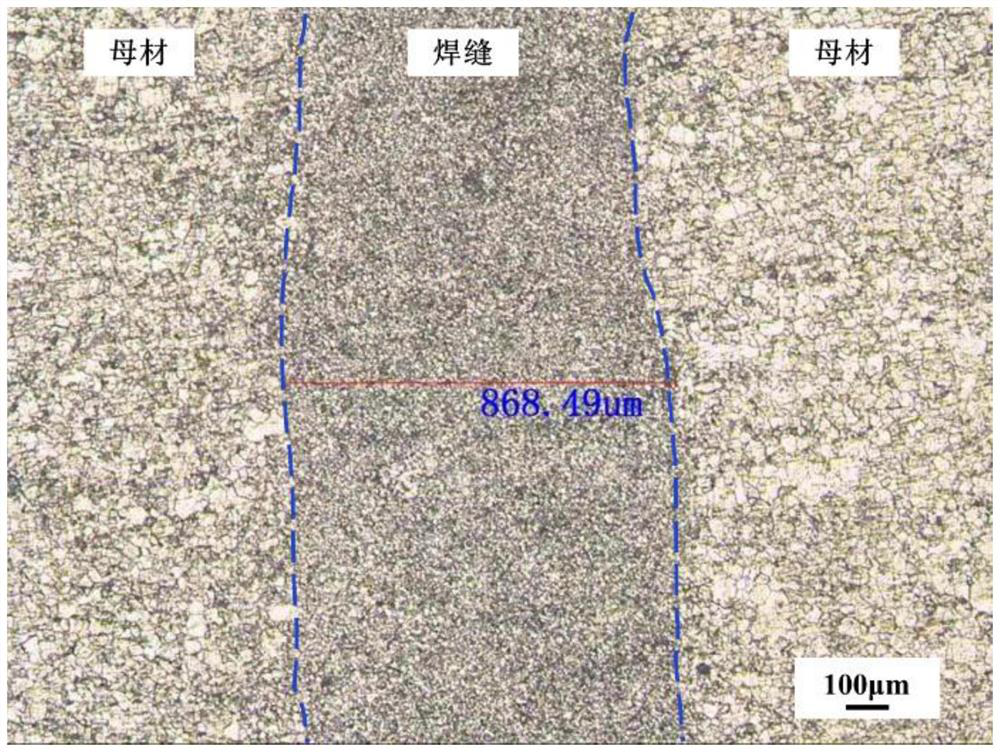

Embodiment 2

[0083] In this example, the 20mm thick aluminum alloy joint is welded by vacuum swing laser welding method. The laser adopts TRUMPF high-power laser with a maximum power of 10000W. The laser head is an IPG swing laser welding head. Other equipment includes a KUKA robot, pumping Vacuum system and vacuum chamber.

[0084] Step 1: Remove the oxide film on the surface of the workpiece to be welded by laser cleaning;

[0085] Step 2: Place the polished, pickled or laser-cleaned workpiece to be welded on the welding workbench in the vacuum chamber, and set the accompanying condensing plate on the workbench. The area of the traveling condensing plate covers at least the aluminum alloy joint. Then fix it with a fixture suitable for the structure and size of the weldment.

[0086] Step 3: Adjust the shape of the oscillating laser spot to a circular spot, align the center of the spot with the center of the starting spot, and adjust the traveling mechanism of the welding platform in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com