Continuous production process and device for anhydrous lithium hydroxide

A technology of anhydrous lithium hydroxide and monohydrate lithium hydroxide, applied in lithium oxide;/hydroxide, chemical industry, sustainable manufacturing/processing, etc., can solve high energy consumption, high labor intensity, easy to be damaged carbonization and other issues, to achieve the effects of reduced energy consumption, low labor intensity, and increased output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

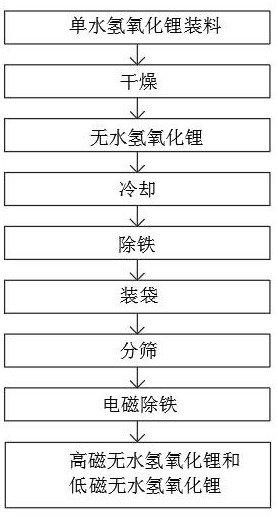

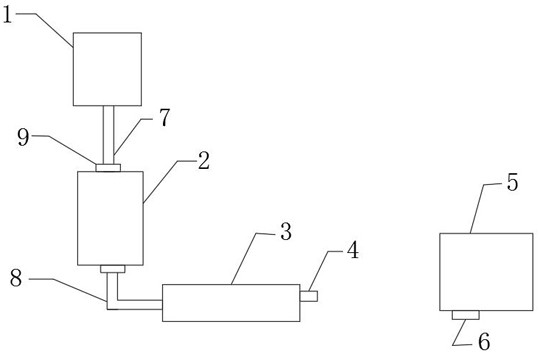

[0017] Embodiment: a kind of anhydrous lithium hydroxide continuous production process, such as figure 1 As shown, it includes the following steps: S1: charging, charging lithium hydroxide monohydrate into the silo 1; S2: drying, adding the lithium hydroxide monohydrate in the silo 1 to the vertical tray through the feeding spiral pipe 7 In the dryer 2, the lithium hydroxide monohydrate performs indirect heat exchange with the heating medium in the vertical tray dryer 2, so that the lithium hydroxide monohydrate absorbs the hot water and evaporates to obtain anhydrous lithium hydroxide; S3: cooling, through water cooling The jacketed screw conveyor 3 cools the anhydrous lithium hydroxide; S4: removes iron, and removes iron from the cooled anhydrous lithium hydroxide through the iron remover 4; S5: packs the bag, and removes the anhydrous hydrogen after iron removal Lithium is packed in bags; S6: sieve, put tons of anhydrous lithium hydroxide into linear vibrating screen silo 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com