High-voltage low-loss ceramic capacitor dielectric and preparation method thereof

A ceramic capacitor and high-voltage technology, applied in the direction of fixed capacitor dielectric, capacitor, fixed capacitor, etc., can solve the problems of high dielectric loss, harm to human body and environment, small dielectric constant, etc., and achieve small dielectric loss, no pollution to the environment, and dielectric The effect of high electric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

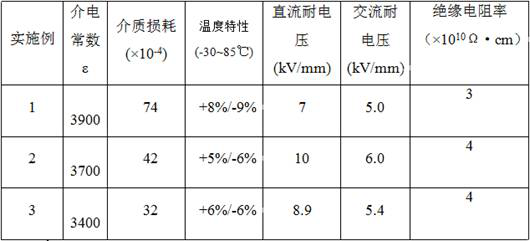

Examples

Embodiment 1

[0023] First, BaTiO was synthesized by the solid-phase method 3 , BaZrO 3 .

[0024] BaTiO 3 Prepared by the following process: Equipped with BaCO in a molar ratio of 1:1 3 and TiO 2 , then for BaCO 3 and TiO 2 Grind and mix well (BaCO 3 and TiO 2 The mixed material is ball-milled, and the weight ratio of the ball-milled mixed material, the ball used, and the water used is: mixed material: ball: water=1:5:1.5, and the ball milling process lasts 4 hours; after the ball milling is completed, the mixed material is dried and passed through an 80-mesh sieve), and then the BaCO 3 and TiO 2 The mixed material was put into an alumina crucible, and kept at 1260 ° C for 180 minutes to obtain BaTiO 3 .

[0025] BaZrO 3 Prepared by the following process: Equipped with BaCO in a molar ratio of 1:1 3 and ZrO 2 , then for BaCO 3 and ZrO 2 Grind and mix well (BaCO 3 and ZrO2 The mixed material is ball-milled, and the weight ratio of the ball-milled mixed material, the ball us...

Embodiment 2

[0038] First, BaTiO was synthesized by the solid-phase method 3 , BaZrO 3 .

[0039] BaTiO in this example 3 , BaZrO 3 The preparation process is the same as in Example 1.

[0040] Then, prepare the high voltage low loss ceramic capacitor dielectric as follows:

[0041] (1) Equipped with BaTiO in proportion 3 , BaZrO 3 , CeO 2 , ZnO, MnCO 3 , La 2 O 3 and W 2 O 3 ;

[0042] The weight percentages of various raw materials prepared in this example are as follows: BaTiO 3 89%, BaZrO 3 6%, CeO 2 0.6%, ZnO 1%, MnCO 3 0.4%, La 2 O 3 2%, W 2 O 3 1%;

[0043] (2) Put the BaTiO prepared in step (1) 3 , BaZrO 3 , CeO 2 , ZnO, MnCO 3 , La 2 O 3 and W 2 O 3 Mix and use a ball mill for ball milling, and then transfer the slurry obtained by ball milling to a sand mill for sand milling;

[0044] In this step (2), a planetary ball mill is used to ball mill the prepared raw materials, and the weight ratio of the ball milled raw materials, the balls used, and ...

Embodiment 3

[0052] First, BaTiO was synthesized by the solid-phase method 3 , BaZrO 3 .

[0053] BaTiO in this example 3 , BaZrO 3 The preparation process is the same as in Example 1.

[0054] Then, prepare the high voltage low loss ceramic capacitor dielectric as follows:

[0055] (1) Equipped with BaTiO in proportion 3 , BaZrO 3 , CeO 2 , ZnO, MnCO 3 , La 2 O 3 and W 2 O 3 ;

[0056] The weight percentages of various raw materials prepared in this example are as follows: BaTiO 3 88.2%, BaZrO 3 7%, CeO 2 0.5%, ZnO 1.2%, MnCO 3 0.5%, La 2 O 3 1.8%, W 2 O 3 0.8%;

[0057] (2) Put the BaTiO prepared in step (1) 3 , BaZrO 3 , CeO 2 , ZnO, MnCO 3 , La 2 O 3 and W 2 O 3 Mix and use a ball mill for ball milling, and then transfer the slurry obtained by ball milling to a sand mill for sand milling;

[0058] In this step (2), a planetary ball mill is used to ball mill the prepared raw materials. The weight ratio of the ball milled raw materials, the balls used, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com