Zinc negative electrode and preparation method and application thereof

A zinc negative electrode and zinc flake technology, applied in the direction of negative electrodes, electrode manufacturing, battery electrodes, etc., can solve the problems of decreased conductivity of the protective layer, limited battery power density, battery polarization that cannot meet high power density, etc., and achieve stability Improved performance, reduced electrochemical reaction impedance, and facilitated large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

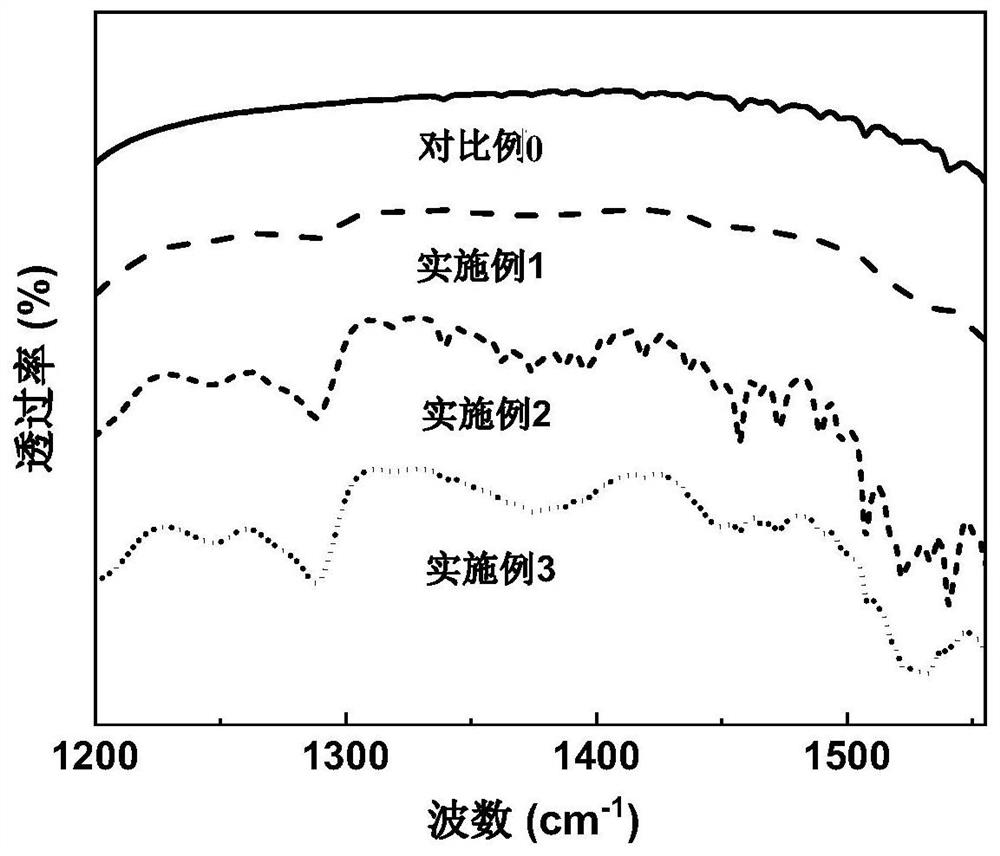

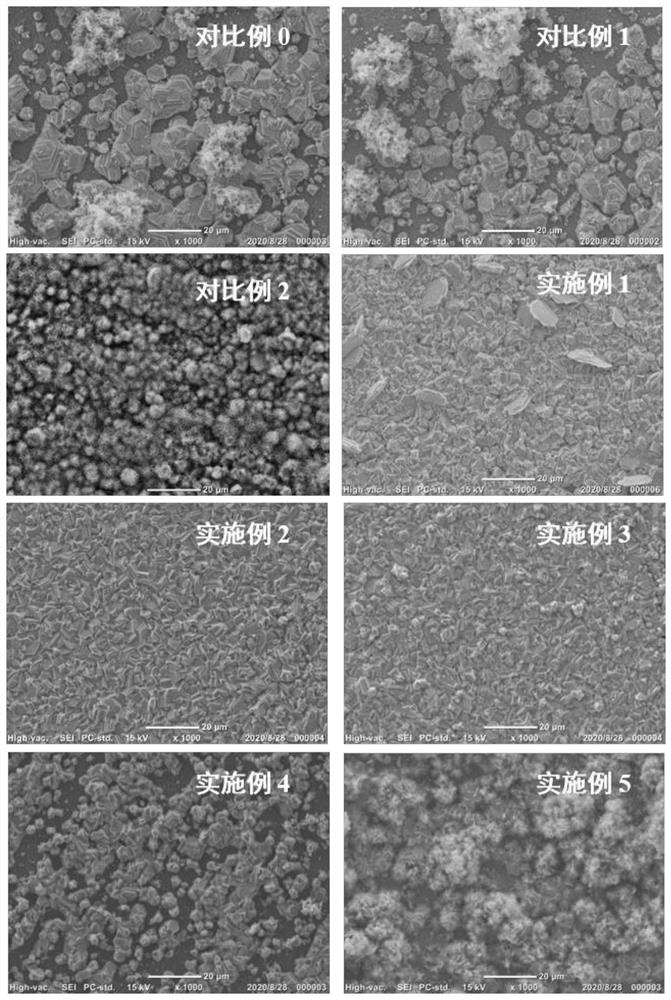

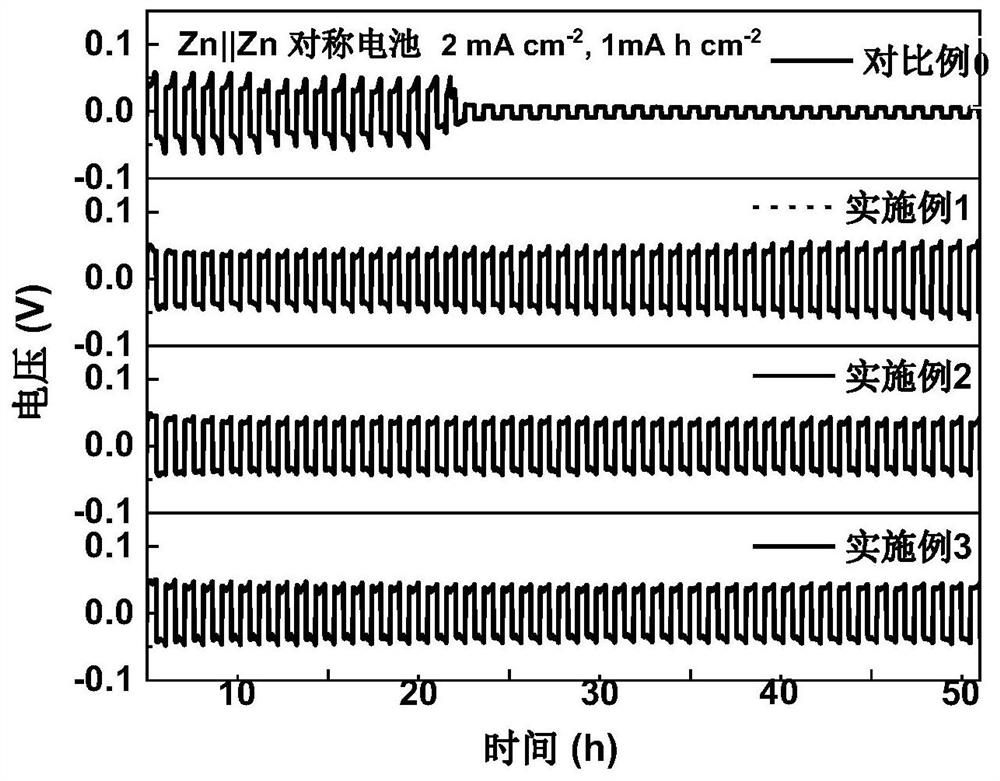

Embodiment 1

[0072] Choose zinc foil with a thickness of 50μm, sand it with 5000-grit sandpaper, and cut it into Electrode pieces of different sizes were ultrasonically cleaned with acetone, ethanol, and water for 10 min in turn. Prepare Tris-HCl (10mmol L -1 ) buffer solution 100 mL, adjust its pH to about 8.5, add dopamine monomer (3 g) and PEG600 (1.5 g) to the solution, and stir until the solution is clear. Take out the cleaned zinc foil, put it into the above-prepared solution, and stir and soak in the air for 24 hours at room temperature. The reacted zinc foil was taken out, rinsed with distilled water for 5 times, and then placed in a freeze dryer for vacuum drying at -40 °C for 6 h. The thickness of the obtained film was determined to be 1 μm.

Embodiment 2

[0074] Choose zinc foil with a thickness of 50μm, sand it with 5000-grit sandpaper, and cut it into Electrode pieces of different sizes were ultrasonically cleaned with acetone, ethanol, and water for 10 min in turn. Prepare Tris-HCl (10mmol L -1 ) buffer solution 100mL, adjust its pH to about 8.5, add dopamine monomer (5g) and PEG600 (2.5g) to the solution, and stir until the solution is clear. Take out the cleaned zinc foil, put it into the above-prepared solution, and stir and soak in the air for 24 hours at room temperature. The reacted zinc foil was taken out, rinsed with distilled water for 3 times, and then placed in a freeze dryer for vacuum drying at -18 °C for 6 h. The thickness of the obtained film was determined to be 3 μm.

Embodiment 3

[0076] Choose zinc foil with a thickness of 50μm, sand it with 5000-grit sandpaper, and cut it into Electrode pieces of different sizes were ultrasonically cleaned with acetone, ethanol, and water for 10 min in turn. Prepare Tris-HCl (10mmol L -1 ) buffer solution 100mL, adjust its pH to about 8.5, add dopamine monomer (7g) and PEG600 (3.5g) to the solution, and stir until the solution is clear. Take out the cleaned zinc foil, put it into the above-prepared solution, and stir and soak in the air for 24 hours at room temperature. The reacted zinc foil was taken out, rinsed with distilled water for 4 times, and then placed in a freeze dryer for vacuum drying at -19 °C for 6 h. The thickness of the obtained film was determined to be 5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com