Preparation method of high-specific-energy Zn/AgO small button type secondary battery

A secondary battery and energy technology, which is applied in the manufacture of secondary batteries, alkaline storage batteries, battery electrodes, etc., can solve the problems of low yield, complex process, and inability to meet the needs of ultra-low temperature environments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

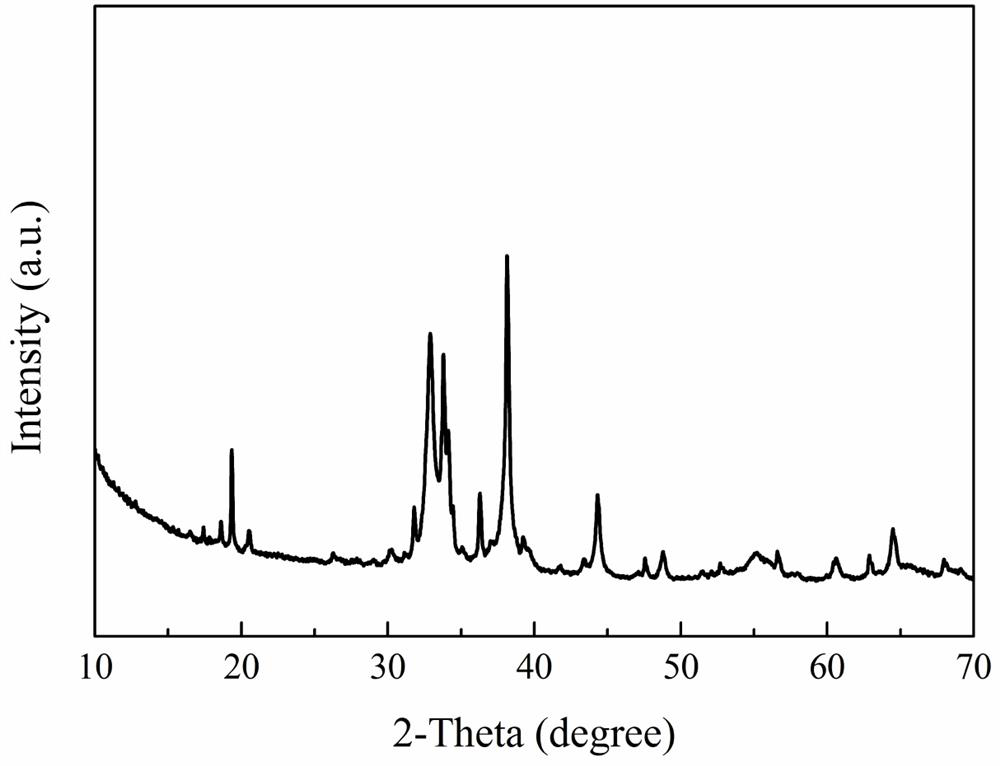

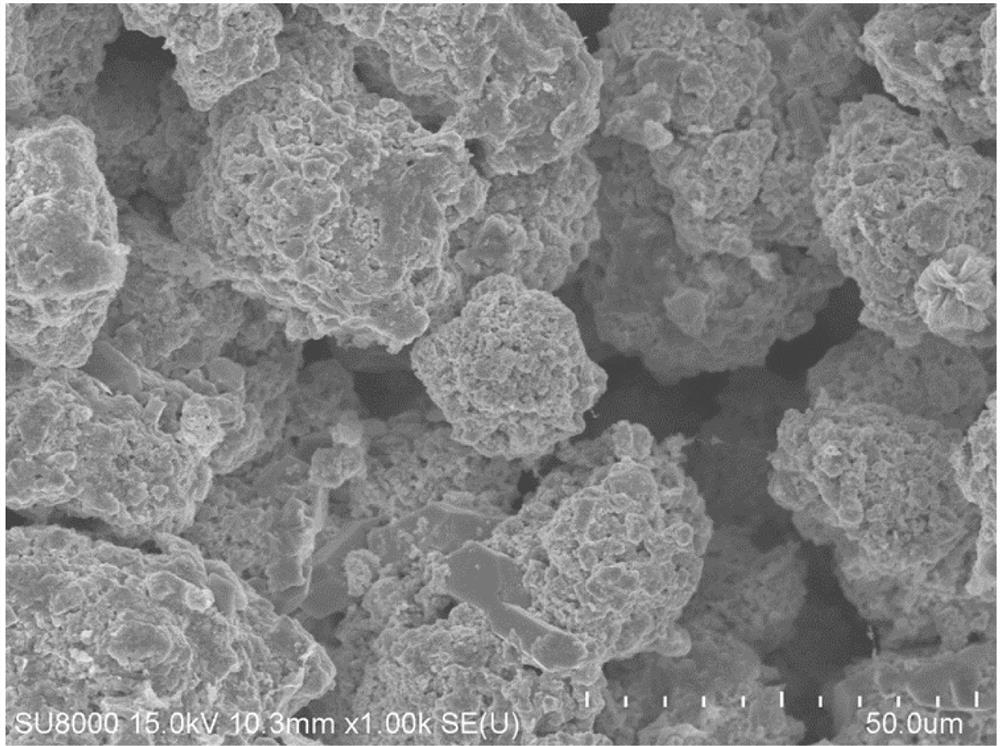

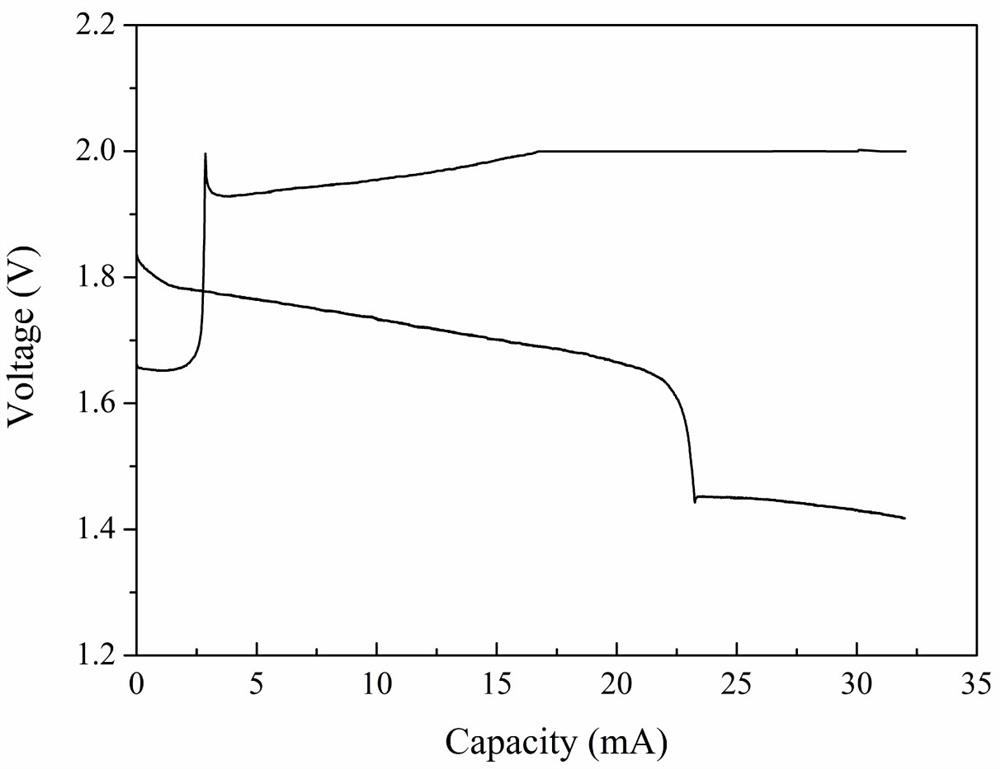

[0031] refer to Figures 1 to 4 As shown, the preparation method of a high specific energy Zn / AgO small button-type secondary battery disclosed in the present invention comprises the following steps:

[0032] Cathode materials were synthesized by chemical methods.

[0033]Disperse spherical silver powder with a particle size of 1-15um is used as the precursor of the electrode material, and the silver powder accounts for 3-30% of the mass of the precursor solution, and the precursor is oxidized to Ag / AgO composite material by using an alkaline sodium persulfate solution as the oxidant , first prepare a highly dispersed aqueous solution with an elemental silver powder content of 5 to 30% in mass, and then prepare a sodium persulfate alkaline solution with a KOH concentration of 2 to 8 mol / L and a sodium persulfate concentration of 0.5 to 5 mol / L. After heating to 50~85℃, mix evenly, keep heating and stirring, the reaction time is 60~120min, finally add PbS alkali solution with ...

Embodiment 2

[0042] The difference from Example 1 is that in this example, the first preparation of KOH concentration is 2~8mol / L, and the sodium persulfate concentration is the oxidant solution of 0.5~5mol / L; 200mL elemental silver powder dispersion liquid and 300mL persulfuric acid The sodium lye solution is heated to 50~85℃, poured into a 1L beaker and kept stirring at a speed of 150~450rad / min, and the mixed solution is heated at the same time to keep the solution temperature in the range of 55~85℃, stirring and heating time For 60-120 min, the mixed solution was cooled, filtered, washed and dried to obtain the Ag / AgO composite material with spherical structure.

[0043] Take 5~20Ag / AgO composite material and add it to 100mL of lead sulfide alkali solution with a mass ratio of 3~10%, react at 65~75℃ for 15~45min, and after the mixed solution is cooled, filter, wash and dry to obtain spherical structure. Ag / AgO / AgPbO composite cathode material.

[0044] Weigh 0.15~0.5g Ag / AgO / AgPbO com...

Embodiment 3

[0046] The difference from Example 1 is that in this example, 400-1200 g of KOH was first dissolved in 2 L of deionized water, 10-50 g of active zinc powder was heated while hot, and after standing for 24 hours, 4-10 mol / L lye was obtained by filtration. Take 1L of KOH lye and a 2L beaker, add potassium fluoride monohydrate, potassium perfluorobutanesulfonate, zinc trifluoromethanesulfonate, zinc laurate, and zinc oxide in turn, wherein the addition amounts are 0.5-1.50mol, 5 ~30mmol, 20 ~ 100mmol, 10 ~ 100mmol, 0.5 ~ 2.5mol, 150 ~ 300rad / min stirring for 30min, then seal the mouth of the beaker and place the beaker in a 60 ℃ oven, heat for 6h, after the solution is cooled, filter, the filtrate is prepared Zn / AgO battery electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com