Cu-doped bismuth sulfide material as well as preparation method and application thereof

A bismuth chloride and raw material technology, applied in the field of Bi2S3 materials, to achieve the effect of improving electrocatalytic activity, simple process conditions, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

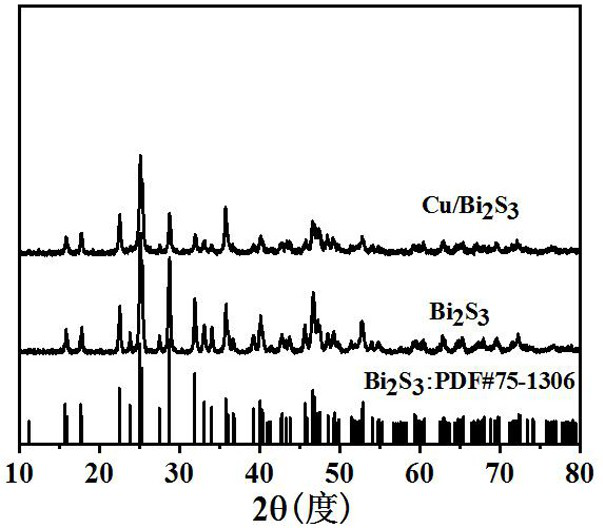

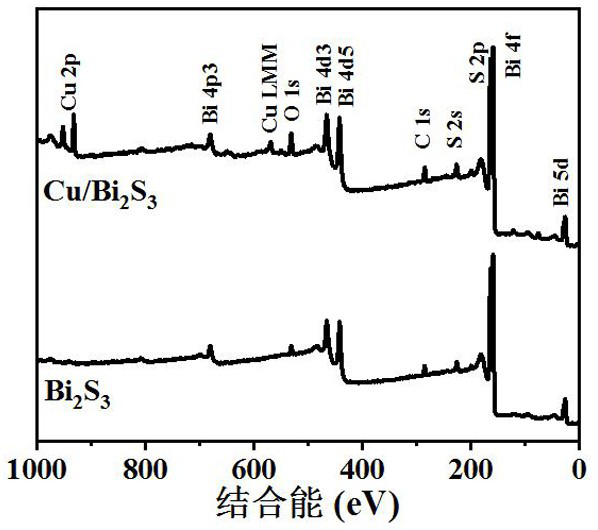

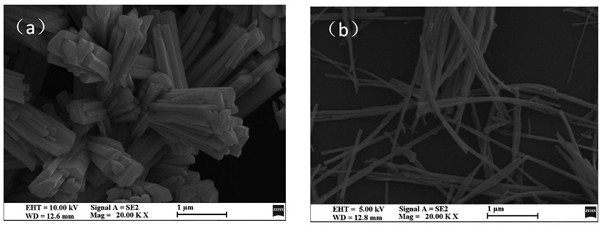

[0027] Put 0.01 g of copper chloride dihydrate and 0.121 g of bismuth chloride in a 250 mL beaker, add 150 mL of deionized water, and then add 8 mL of concentrated hydrochloric acid (37% by mass), stir to make it clear solution, then add 0.687g of thioacetamide, stir vigorously for 20 minutes, then place it in a polytetrafluoroethylene hydrothermal reactor, and then place the reactor in an oven and keep it at 160 °C for 6 hours. The obtained samples were washed with ethanol, centrifuged three times, and vacuum dried to obtain Cu / Bi 2 S 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com