Light emitting diode epitaxial wafer and preparation method thereof

A technology of light-emitting diodes and epitaxial wafers, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as lattice mismatch and reduce the luminous efficiency of light-emitting diode epitaxial wafers, so as to reduce the degree of influence, facilitate strain relaxation, The effect of enhancing limited abilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

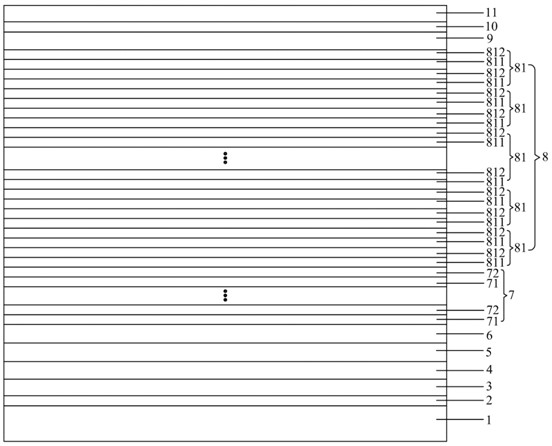

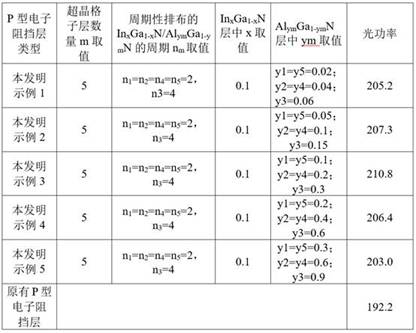

[0038] see figure 1, is a schematic structural diagram of a light-emitting diode epitaxial wafer provided by an embodiment of the present invention. For the convenience of description, only the part related to the embodiment of the present invention is shown. The light-emitting diode epitaxial wafer provided by the embodiment of the present invention includes: a substrate 1 , and a buffer layer 2, a three-dimensional nucleation layer 3, a two-dimensional recovery layer 4, an undoped GaN layer 5, an N-type GaN layer 6, a multiple quantum well layer 7, and a P-type electron blocking layer stacked in sequence on the substrate 1 layer 8, P-type undoped GaN layer 9, P-type Mg-doped GaN layer 10 and P-type contact layer 11; wherein the P-type electron blocking layer 8 includes m superlattice structure sublayers 81; Layer 81 is composed of n m A periodically arranged In x Ga 1-x N / Al ym Ga 1-ym A superlattice structure composed of N; along the direction from the multiple quantum...

Embodiment 2

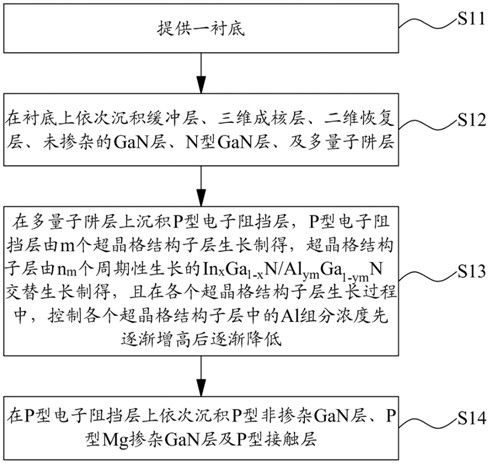

[0067] see figure 2 , which shows a method for preparing a light-emitting diode epitaxial wafer in the second embodiment of the present invention, and the method specifically includes steps S11 to S14 .

[0068] Step S11, providing a substrate.

[0069] Wherein, in this embodiment of the present invention, the selected substrate may be any one of a sapphire substrate, a silicon substrate, a silicon carbide substrate, and a gallium nitride substrate. Specifically, in this embodiment, sapphire is used as the substrate. The epitaxial layer growth substrate, which may specifically be a patterned sapphire substrate or a sapphire flat substrate.

[0070] Further, the present invention uses metal organic chemical vapor deposition (MOCVD) equipment to grow epitaxial wafers. Among them, high-purity ammonia (NH 3 ) as N (nitrogen) source, trimethylgallium (TMGa) and triethylgallium (TEGa) as Ga (gallium) source, trimethylindium (TMIn) as In (indium) source, trimethylaluminum (TMAl) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com